Trainee Guide TR-L2-M2000

Level 2 Maintenance Training – M2000 Dispensing Systems 4-2-36 P/N 73-0018-00 (Revision B)

Information Sheet 4-8-13

DJ-2000 Troubleshooting (Continued)

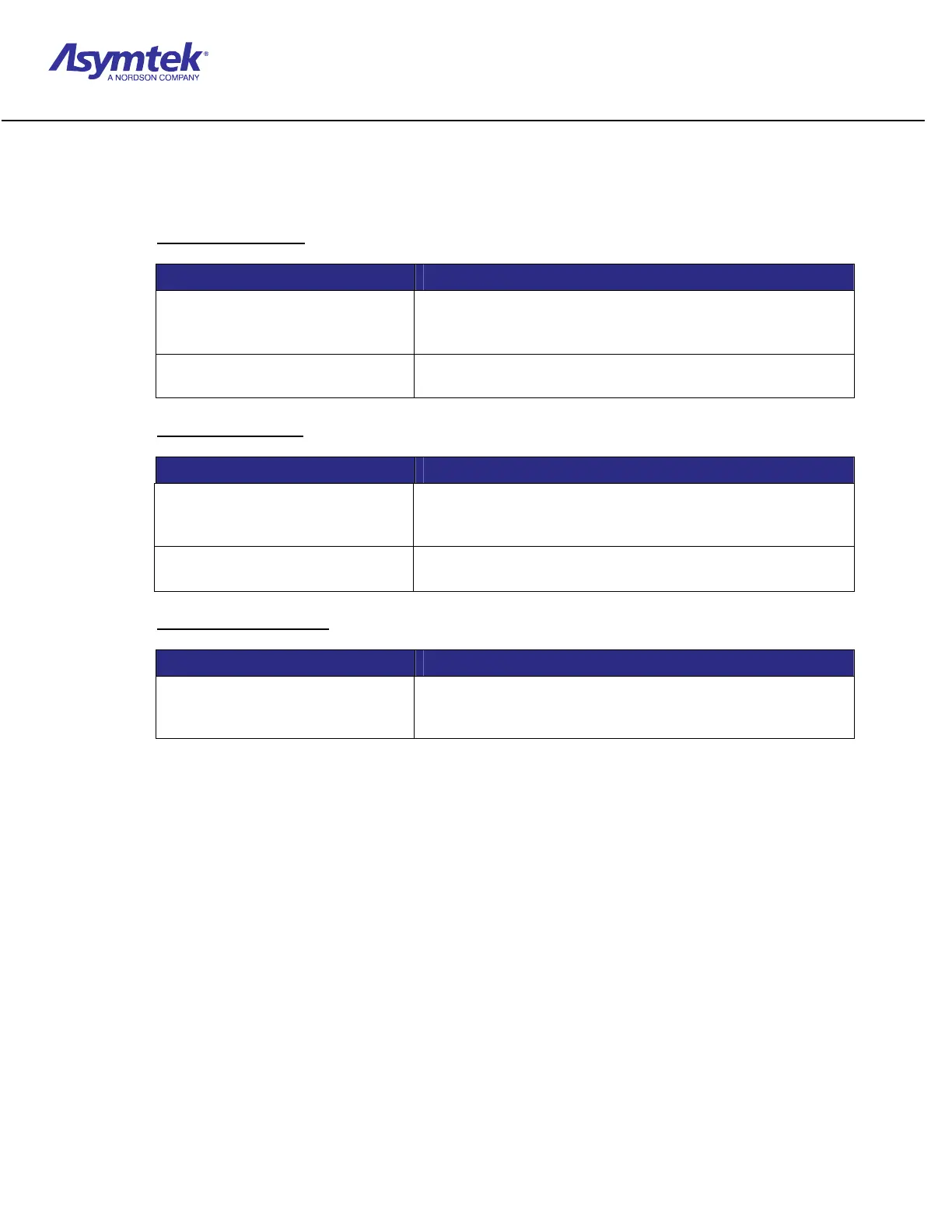

Q. Dots Are Too Flat

Possible Cause Recovery

1. Dispenser heater temperature

too high

1. Reduce temperature 2°C (3.6°F) at a time. Refer to

Section 4 – Heater Control for Windows (HCW) of the

Fluidmove for Windows Installation and User Guide.

2. Micrometer setting is too high

2. Reduce the needle stroke by rotating the micrometer

clockwise.

R. Dots Are Too Tall

Possible Cause Recovery

1. Dispenser heater temperature

is too low

1. Increase the temperature 2°C (3.6°F) at a time. Refer to

Section 4 – Heater Control for Windows (HCW) of the

Fluidmove for Windows Installation and User Guide.

2. Micrometer setting is too low

2. Increase the needle stroke by rotating the micrometer

counterclockwise.

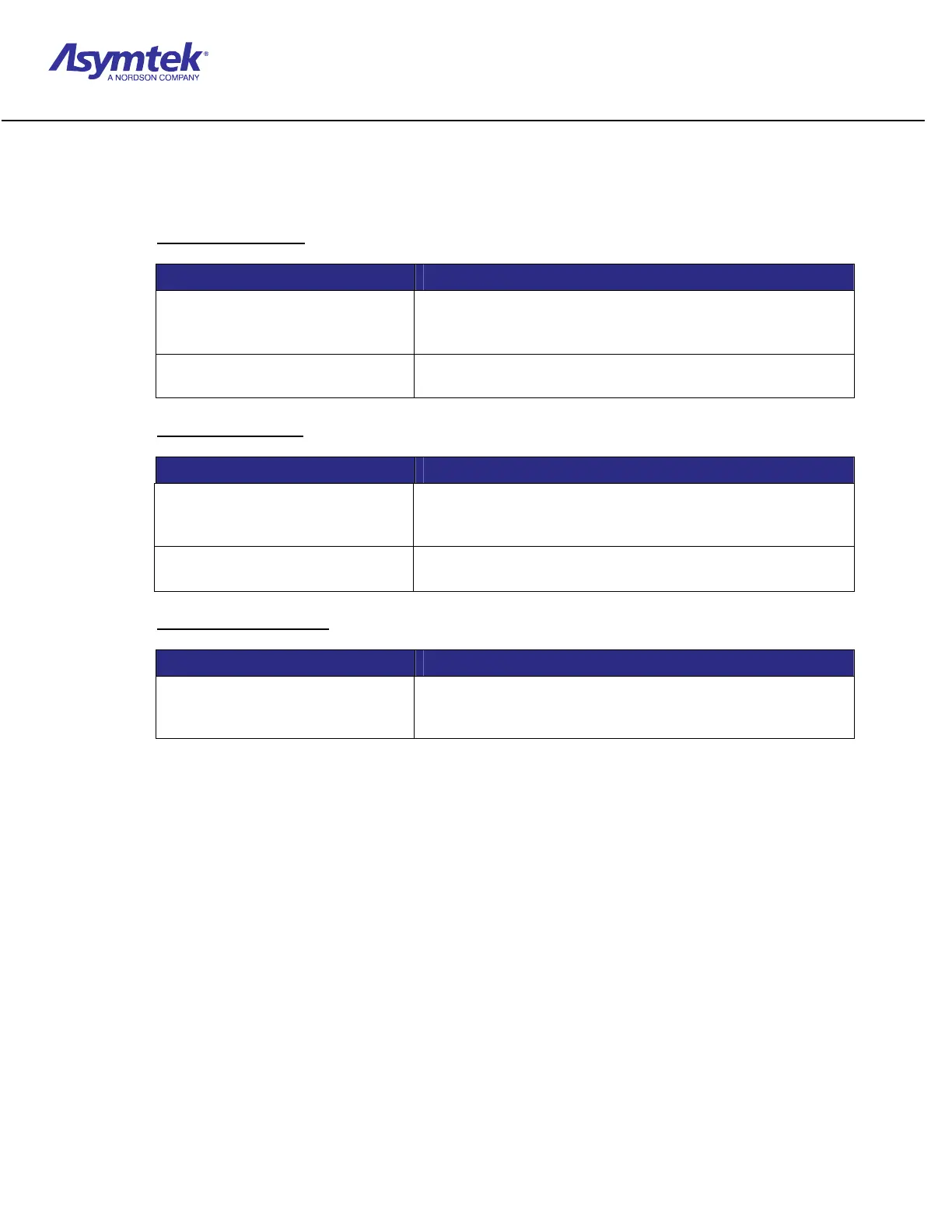

S. Skipping Some Dots

Possible Cause Recovery

1. Air has gotten into the pump,

possibly from disassembly.

1. Prime the DJ-2000. Refer to the procedure, “To

manually prime the DJ-2000” in DJ-2000 Operations

Manual.

Loading...

Loading...