MC_TimeStampToPos

The MC_TimeStampToPos instruction calculates the position of the axis for the specified time stamp.

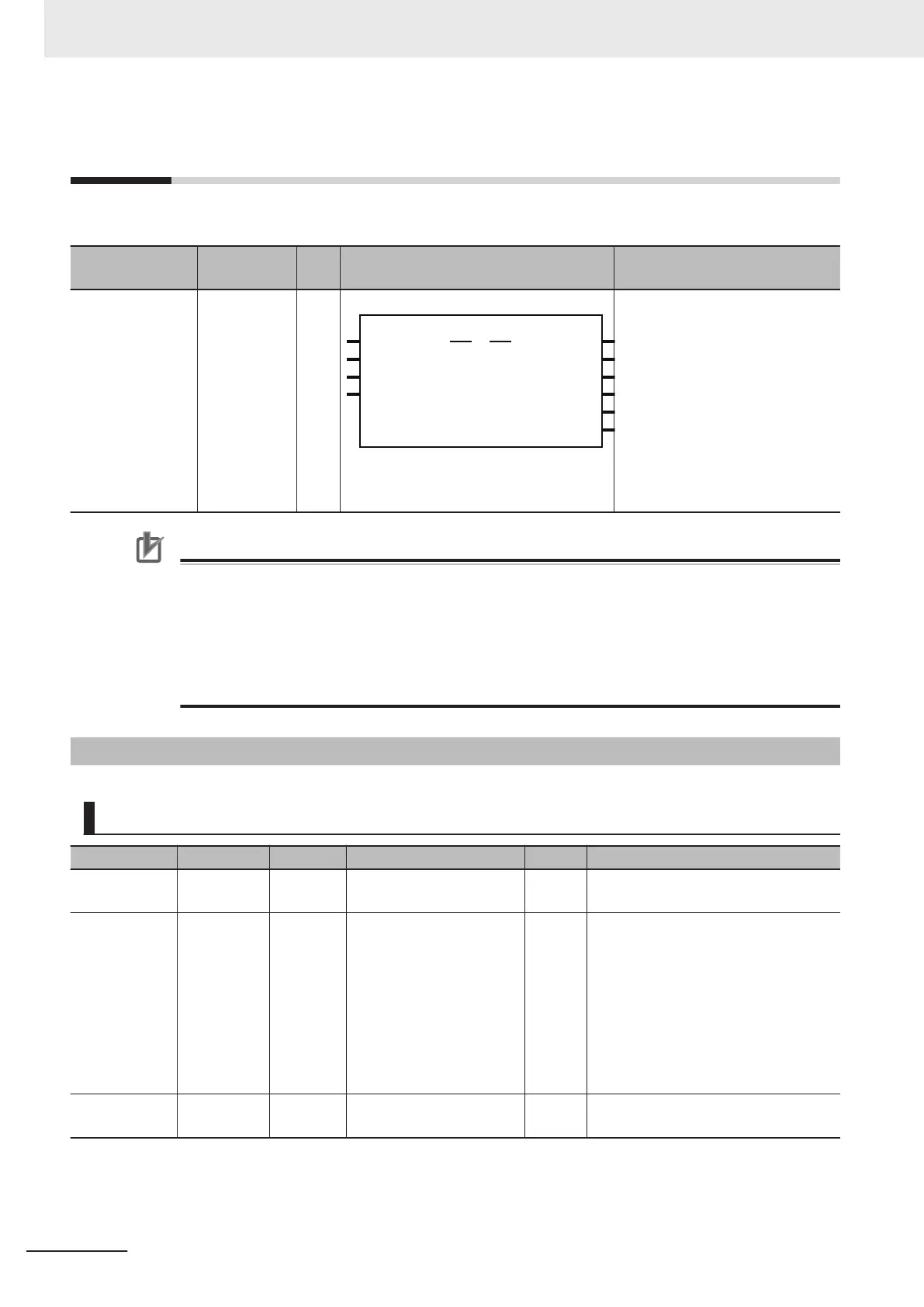

Instruction Name

FB/

FUN

Graphic expression ST expression

MC_TimeStamp-

T

oPos

Time Stamp

to Axis Posi-

tion Calcula-

tion

FB

MC_TimestampToPos_instance

Axis

Axis

Enable Enabled

Timestamp Busy

Error

ErrorID

MC_TimestampToPos

ValueSource CalcPosition

MC_TimeStampToPos_instance (

Axis :=parameter,

Enable :=parameter,

T

imeStamp :=parameter,

ValueSource :=parameter,

Enabled =>parameter,

Busy =>parameter,

CalcPosition =>parameter,

Error =>parameter,

ErrorID =>parameter

);

Precautions for Correct Use

• You can use this instruction for the following Units.

a) An axis that is assigned to an NX-series Position Interface Unit.

The applicable NX Units are as follows: NX-EC0£££

and NX-ECS£££.

b) An OMRON 1S-series Servo Drive with built-in EtherCAT communications.

•

When you use this instruction for an OMRON 1S-series Servo Drive with built-in EtherCAT

communications, you must assign the Object 3211-83 hex (Present Position Time Stamp) to

a PDO.

Variables

Input Variables

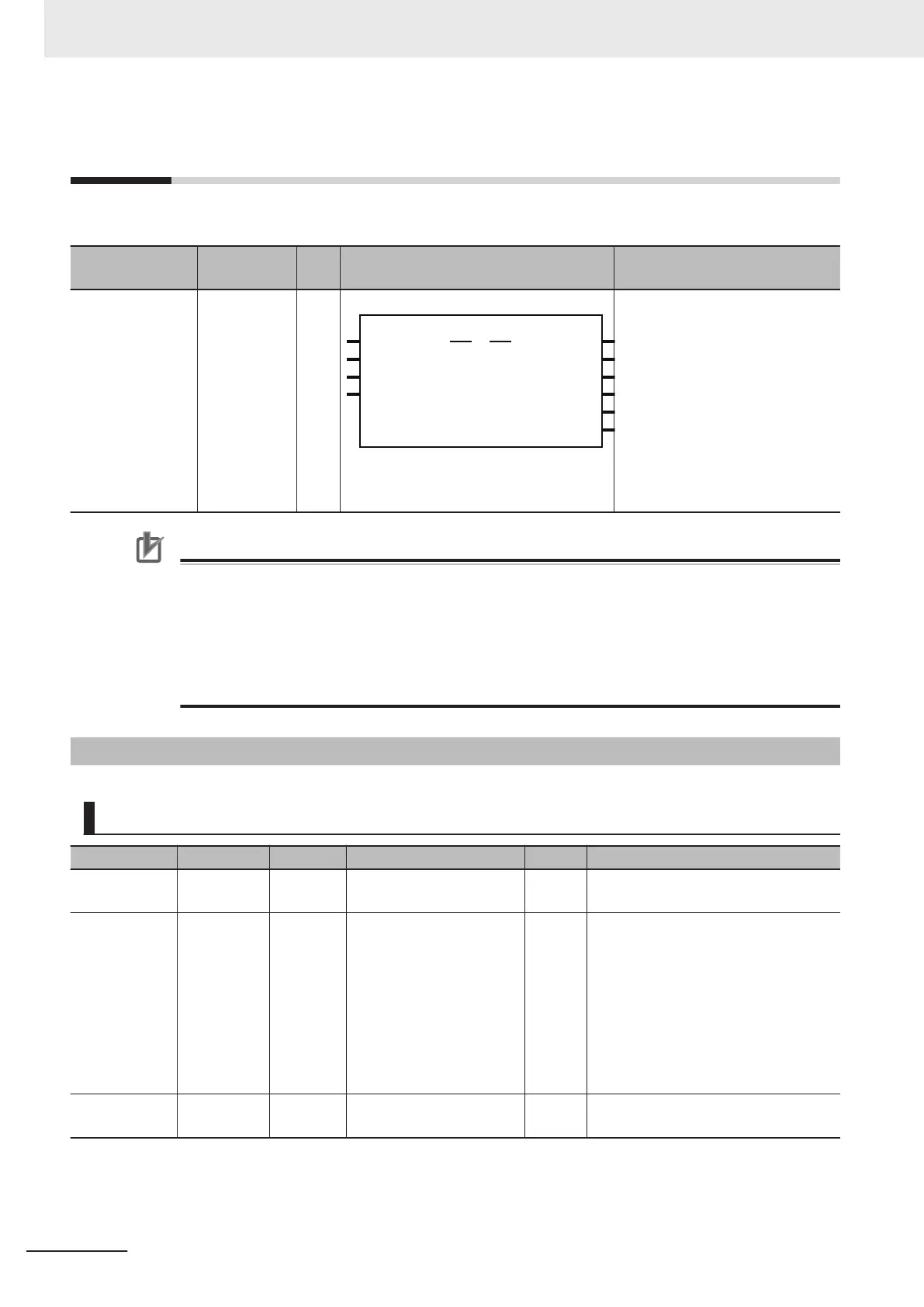

Name Meaning Data type Valid range Default Description

Enable Enable BOOL TRUE or FALSE FALSE The instruction is executed while the

value of this variable is TRUE.

TimeStamp Time Stamp ULINT Non-negative number 0 Specifies the time stamp for which to

calculate the position.

A time stamp that is based on the time

in a Digital Input Unit, Encoder Input

Unit, or OMRON 1S-series Servo

Drive with built-in EtherCA

T communi-

cations that supports time stamp re-

freshing is specified. The unit is nano-

seconds.

ValueSource

(Reserved)

Input Infor-

mation

_sMC_S

OURCE

--- --- (Reserved)

3 Axis Command Instructions

3-436

NY-series Motion Control Instructions Reference Manual (W561)

Loading...

Loading...