MC_AxesObserve

The MC_AxesObserve instruction monitors the deviation between the command positions or the ac-

tual positions for the specified axes to see if it exceeds the allowed value.

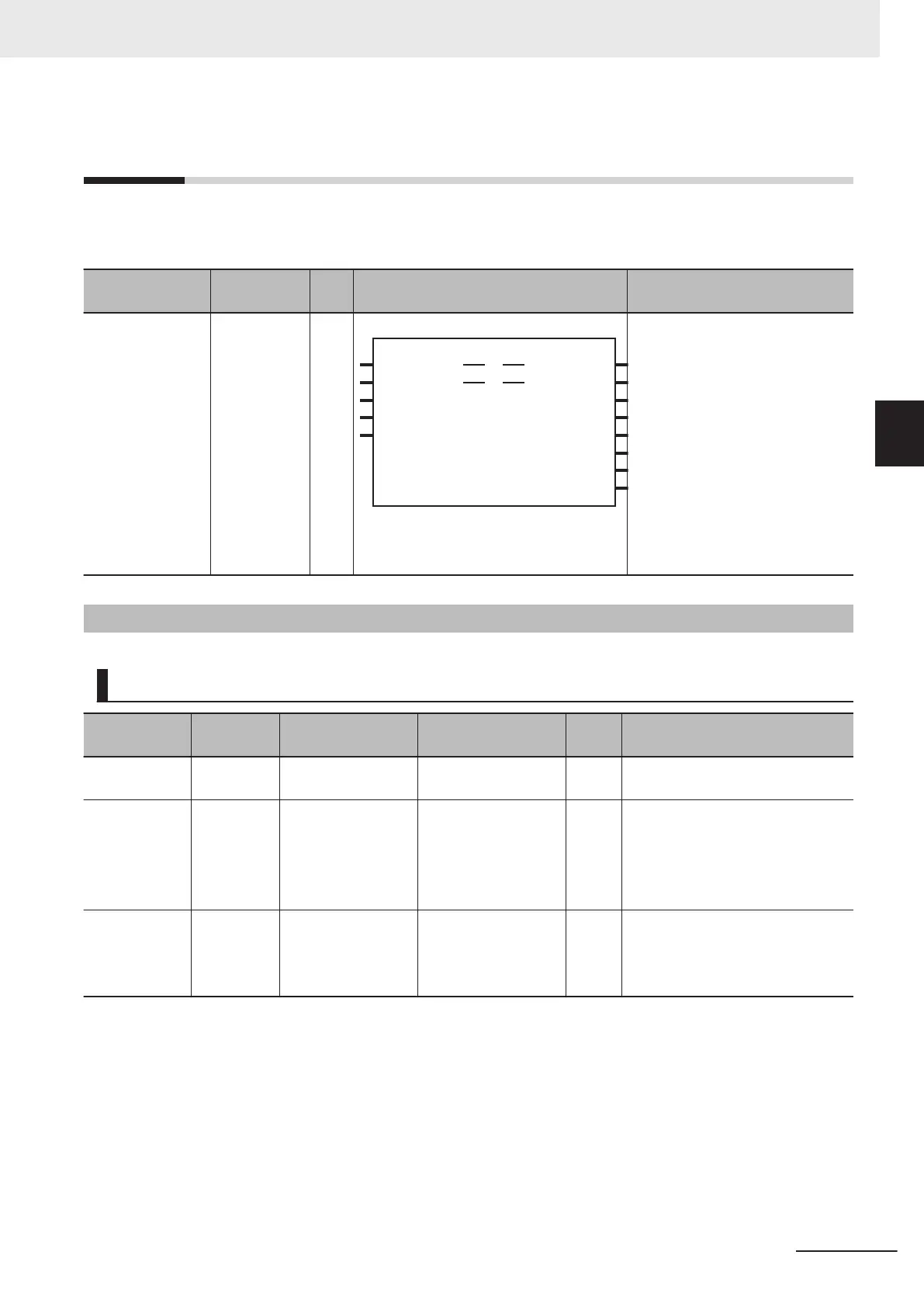

Instruction Name

FB/

FUN

Graphic expression ST expression

MC_AxesObserve Monitor Axis

Following Er-

ror

FB

MC_AxesObserve_instance

Invalid

Master Master

Slave Slave

Enable Enabled

PermittedDeviation

DeviatedValue

Error

ErrorID

MC_AxesObserve

ReferenceType

Busy

MC_AxesObserve_instance (

Master :=parameter,

Slave :=parameter,

Enable :=parameter,

ReferenceT

ype :=parameter,

PermittedDeviation :=parameter,

Enabled =>parameter,

Invalid =>parameter,

Busy =>parameter,

DeviatedValue =>parameter,

Error =>parameter,

ErrorID =>parameter

);

Variables

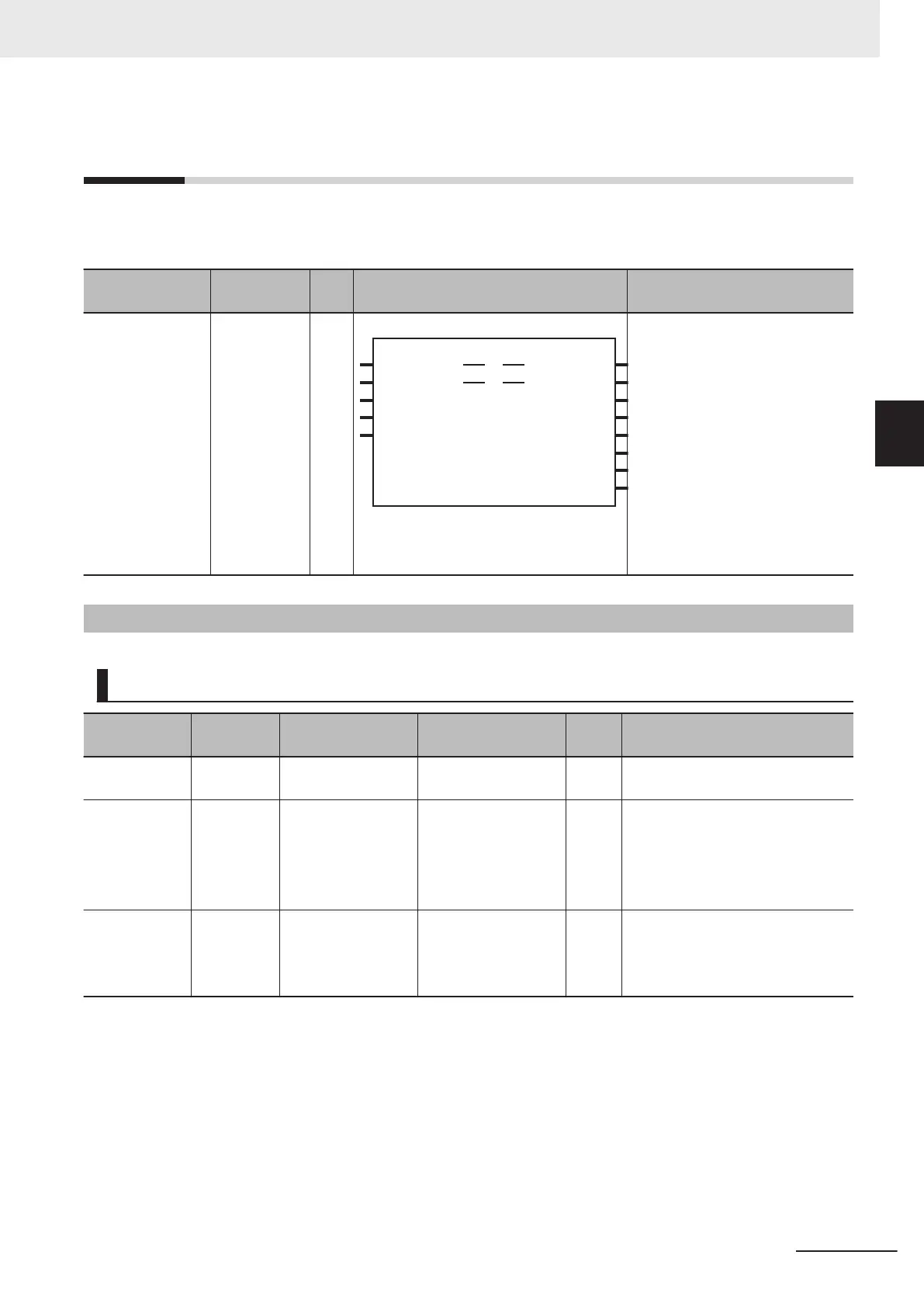

Input Variables

Name Meaning Data type Valid range

De-

fault

Description

Enable Enable BOOL TRUE or FALSE FALS

E

The instruction is executed when

the value of this variable is TRUE.

ReferenceType Position

T

ype Selec-

tion

_eMC_RERER-

ENCE_TYPE

0: _mcCommand

1: _mcFeedback

0

*1

Specify the position type.

0: Command position (value calcu-

lated in the previous task period

*2

)

1: Actual position (value obtained

in the same task period

*2

)

PermittedDevi-

ation

Permitted

Following

Error

LREAL Non-negative number 0 Specify the permitted maximum

value of the following error be-

tween the master and slave axes.

The unit is command units.

*3

*1. The default value for an enumeration variable is actually not the number, but the enumerator.

*2. The task period is the primary period.

*3. Refer to Unit Conversion Settings in the NY

-series Industrial Panel PC / Industrial Box PC Motion Control User’s

Manual (Cat. No. W559) for information on command units.

3 Axis Command Instructions

3-385

NY-series Motion Control Instructions Reference Manual (W561)

MC_AxesObserve

3

Variables

Loading...

Loading...