Workshop

Manual

Rolls Royce Silver

Shadow

8

Bentley

T

Ser~es

Chapter

J

The spring balance reading obtained to initially

rotate the pinion will be high.

It is the lower steady

reading when the pinion is rotating, which indicates

the

pre:loading.

9. If the pre-load is not correct the pinion must

be

extracted from the housing and the adjusting washers

changed

as

necessary to obtain the correct reading.

Adjusting washers are available in a range from

0.105 in. to 0.110 in. (2,66

rnm.

to 2,79 mm.) and

0.1

10 in. to 0.160 in. (2,79

mm.

to 4,06

mm.)

in 0.001

in.

(0,025

mm.)

and 0.005 in. (0,127 mm.) increments

respectively.

Reducing the combined thickness of the washers

will increase the pre-load and increasing the thickness

will

reduce it but, it must

be

noted that very small

changes to the thickness of the washers has a marked

effect on the pre-load figure.

0

K

IW

10. When the pinion has been pre-loaded correctly,

turn over the tab on the lock-washer fitted under the

FIG.

57

STAMPED DIMENSION ON FINAL DRIVE

pinion flange retaining nut.

CASING

between

8

lb. in. and 10 lb.

in.

(0,092 kg.m. and 0,115

kg.m.) and this is best checked using

a

spring balance

pulling on a bolt inserted into one of the holes

in

the

pinion flange.

Note

The holes

in

the pinion flange

are

1.875 in.

(4,762

cm.)

away from the centre of the

pinion

and

therefore

if

this method

is

used

the spring balance reading should

be

between 4.3

Ib.

and

5.3

Ib.

(1,949

kg. and 2,403 kg.).

Final

drive

unit-To

assemble

To assemble the final drive unit reverse the procedure

given for dismantling ensuring that the crown wheel

and pinion are in their correct relative positions and

that there

i?l

the correct amount of backlash between

the two gears.

All

parts

must be cleaned thoroughly prior to

assembly and all bearings, other than new ones,

lubricated.

1.

Before commencing to assemble the final drive

unit, the

stiffening bar

(RH

8032) should be fitted to

0

the

final

drive casing.

2.

Partly screw four

Q

in.

U.N.F.

studs into the

threaded holes in the front of the final drive casing.

It is sufficient to fit these studs

by

hand as they serve

only as location pegs for the pinion housing.

3.

If the pinion nose bearing was removed from the

casing previously, fit the bearing, and the two socket

headed retaining screws, nuts and washers.

Note the dimension stamped on the cast rib, just

above the front flange of the

final drive casing (see

Fig.

J7).

!~157

4.

Place the differential casing in an oven at a

temperature of 80°C

(176°F)

for &oximately

1

hour.

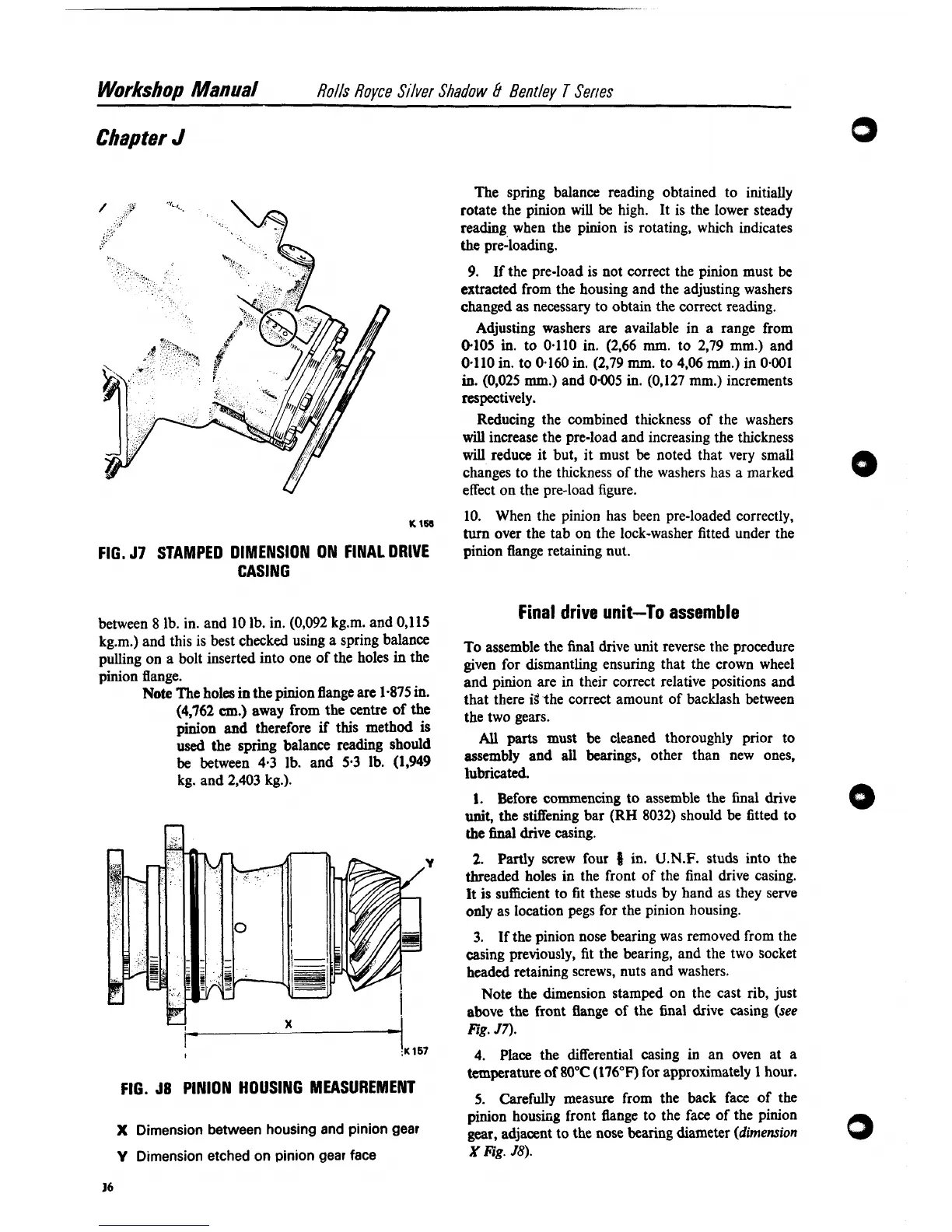

FIG.

J8

PINION HOUSING MEASUREMENT

5. Carefa measure from the back face of the

pinion

housiig front flange to the face of the pinion

X

Dimension between housing and pinion gear

gear, adjacent to the nose bearing diameter

(dimension

0

V

Dimension etched on pinion

gear

face

X

Fig.

58).

Loading...

Loading...