Workshop

Manual

Rolls- Royce Silver Shadow

&

Bentley

T

Series

Chapter

M

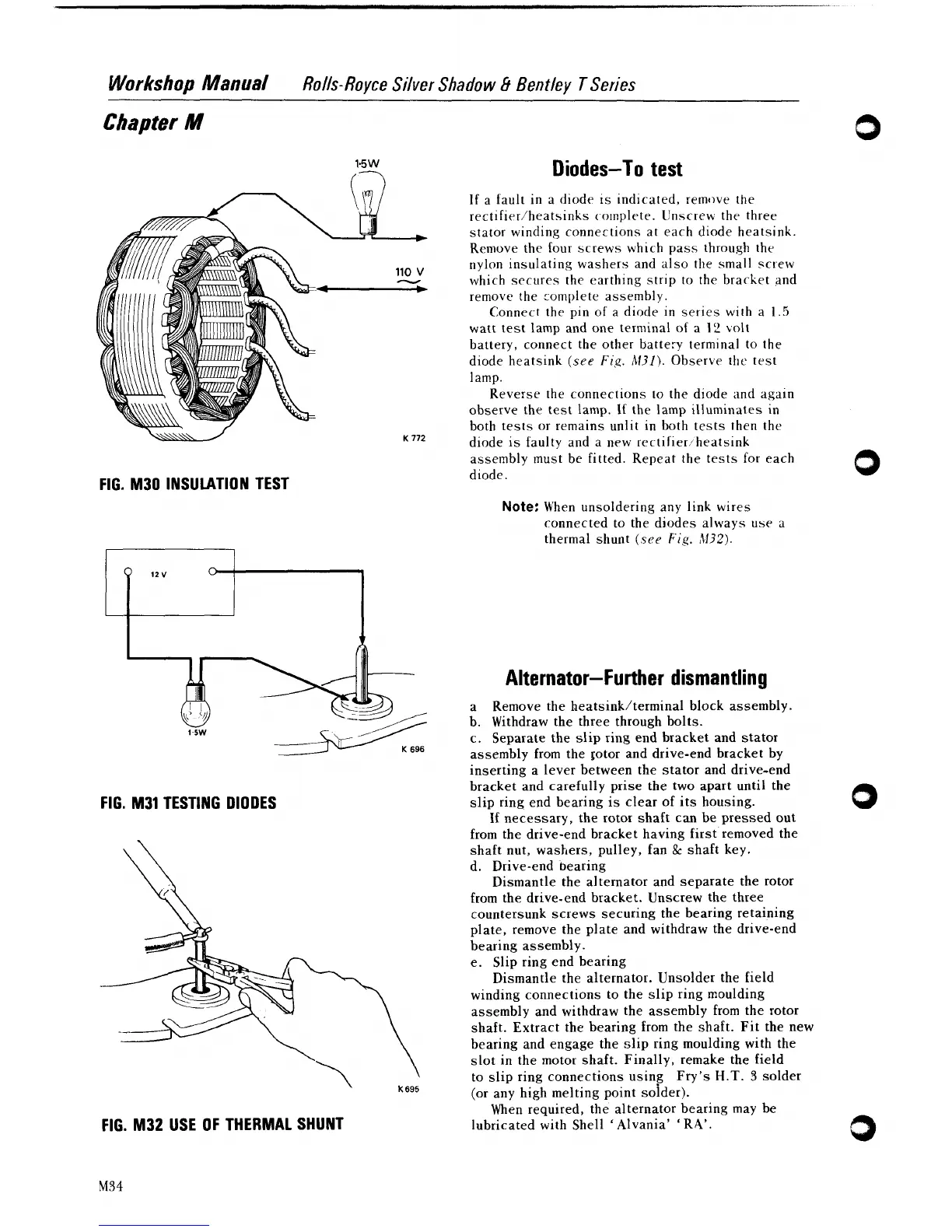

FIG. M30 INSULATION TEST

diode.

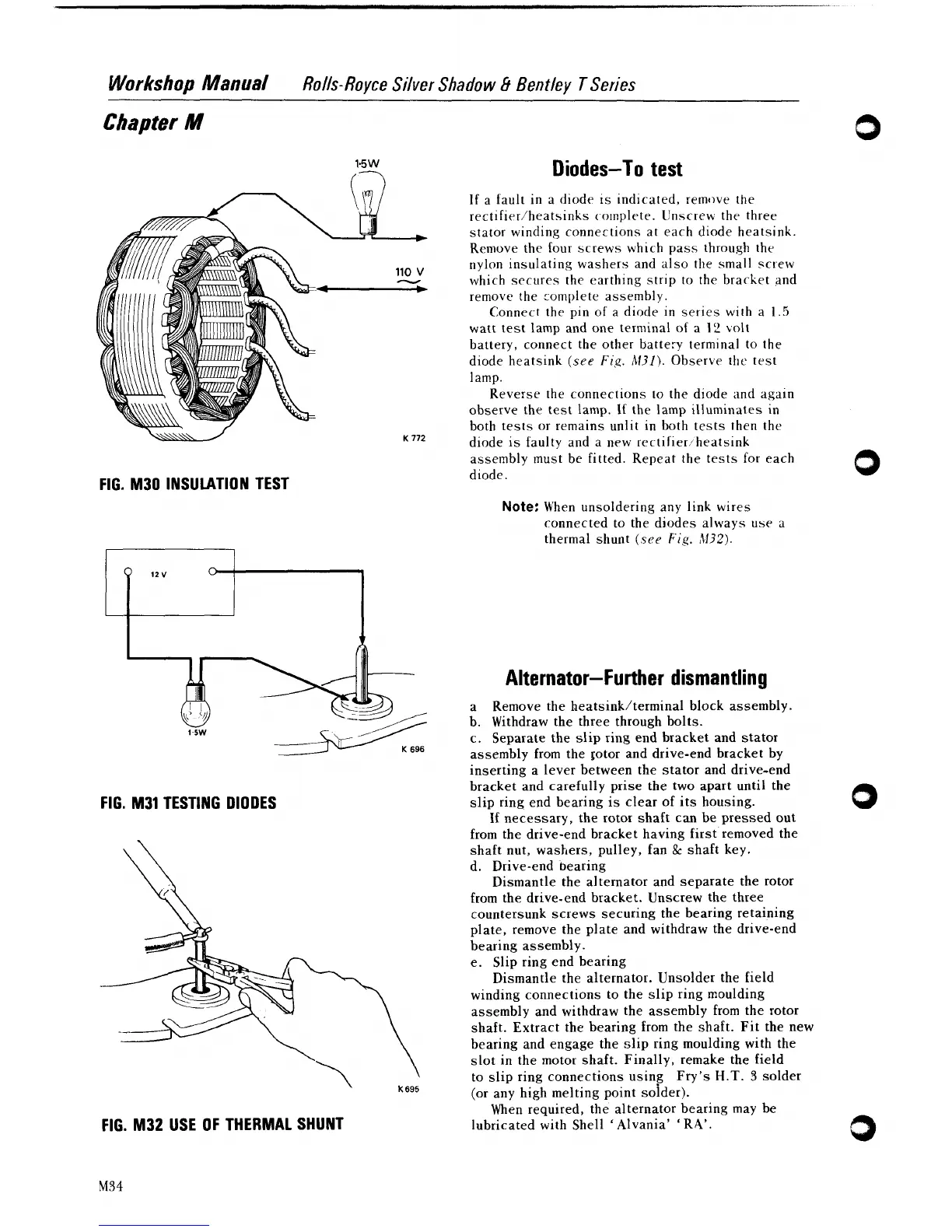

FIG. M31 TESTING DIODES

Diodes-To test

If

a fault in a diode is indicated, remove the

rectifier/heatsinks cotnplete. Unscrew the three

stator winding connections at each diode heatsink.

Remove the four screws which pass through the

nylon insulating washers and also the small

screw

which secures the earthing strip to the bracket and

remove the complete assembly.

Connect the pin of a diode

in

series with a 1.5

watt test lamp and one

terminal

of

a 12 volt

battery, connect the other

battery terminal to the

diode

heatsink

(see

Fig.

12131).

Observe the test

lamp.

Reverse the connections to the diode and again

observe the test lamp.

If

the lamp illuminates in

both tests or remains unlit in both tests then the

diode is faulty and

a

new rectifier./heatsink

assembly must be fitted. Repeat the tests for each

FIG. M32 USE OF THERMAL SHUNT

Note:

When unsoldering any link wlres

connected to the diodes always use

a

thermal shunt

(see

FIR.

,2132).

Alternator-Further dismantling

a

Remove the

heatsink/terminal block assembly.

b. Withdraw the three through bolts.

c. Separate the slip ring end bracket and stator

assembly from the

gotor and drive-end bracket by

inserting a lever between the stator and drive-end

bracket and carefully prise the two apart until the

slip ring end bearing is clear of its housing.

If necessary, the rotor shaft can

be

pressed out

from the drive-end bracket having first removed the

shaft nut, washers, pulley, fan

&

shaft key.

d. Drive-end bearing

Dismantle the alternator and separate the rotor

from the drive-end bracket. Unscrew the three

countersunk screws securing the bearing retaining

plate, remove the plate and withdraw the drive-end

bearing assembly.

e. Slip ring end bearing

Dismantle the alternator.

Unsolder the field

winding connections to the slip ring moulding

assembly and withdraw the assembly from the rotor

shaft. Extract the bearing from the shaft. Fit the new

bearing and engage the slip ring moulding with the

slot in the motor shaft. Finally, remake the field

to slip ring connections using Fry's

H.T.

3

solder

(or any high melting point solder).

When required, the alternator bearing may be

lubricated with Shell

'

Alvania'

'

R4'.

3

Loading...

Loading...