Workshop

Manual

Rolls Royce Silrer Shadow

8

Bentley

T

Ser~es

Chapter

J

9.

Thoroughly clean the half-shaft and visually

inspect the shaft bearing bores and trunnion pin for

signs of damage, cracks or surface flaws.

10.

Inspect the ball and trunnion joint seal for

serviceability;

if

necessary it should be renewed.

Ball and trunnion joint seal-To renew

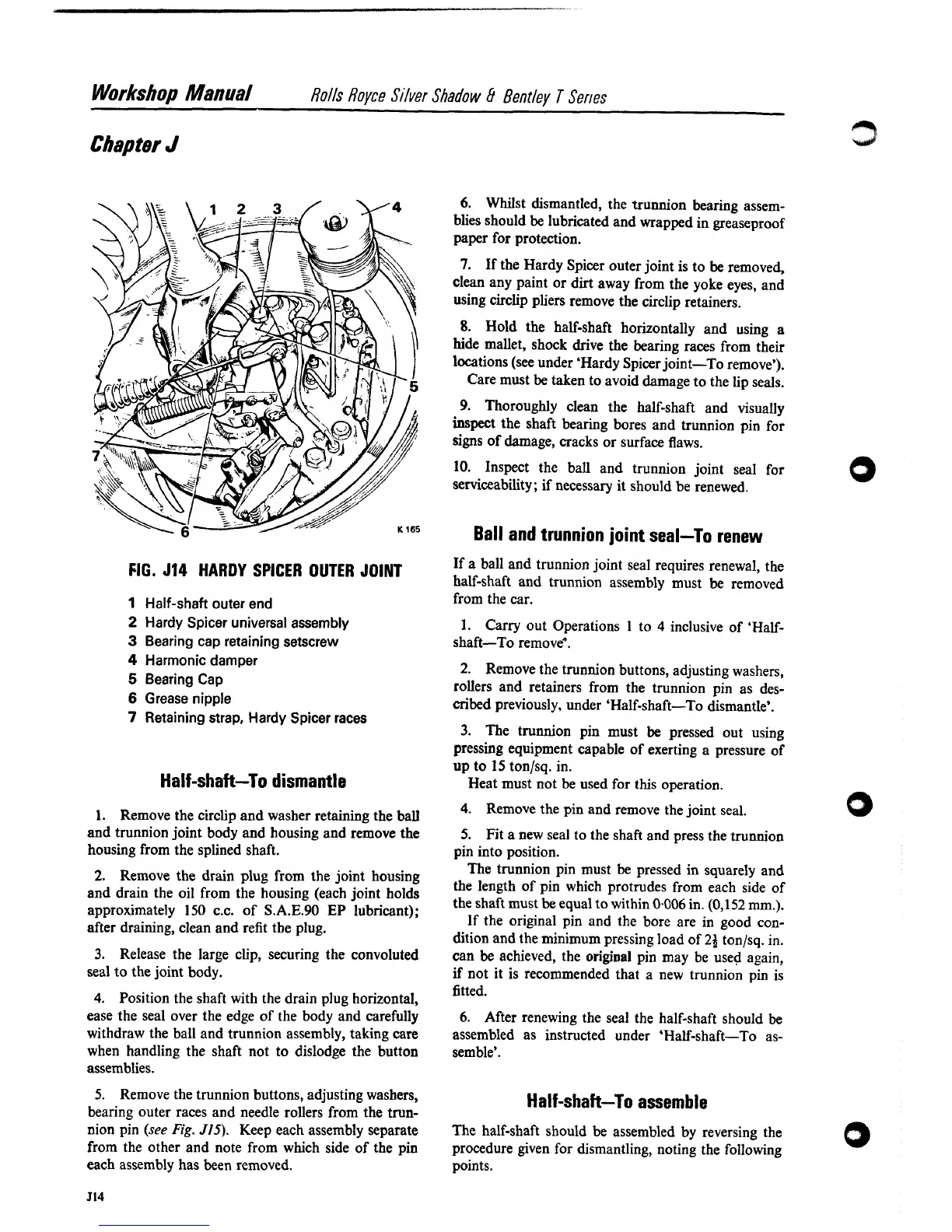

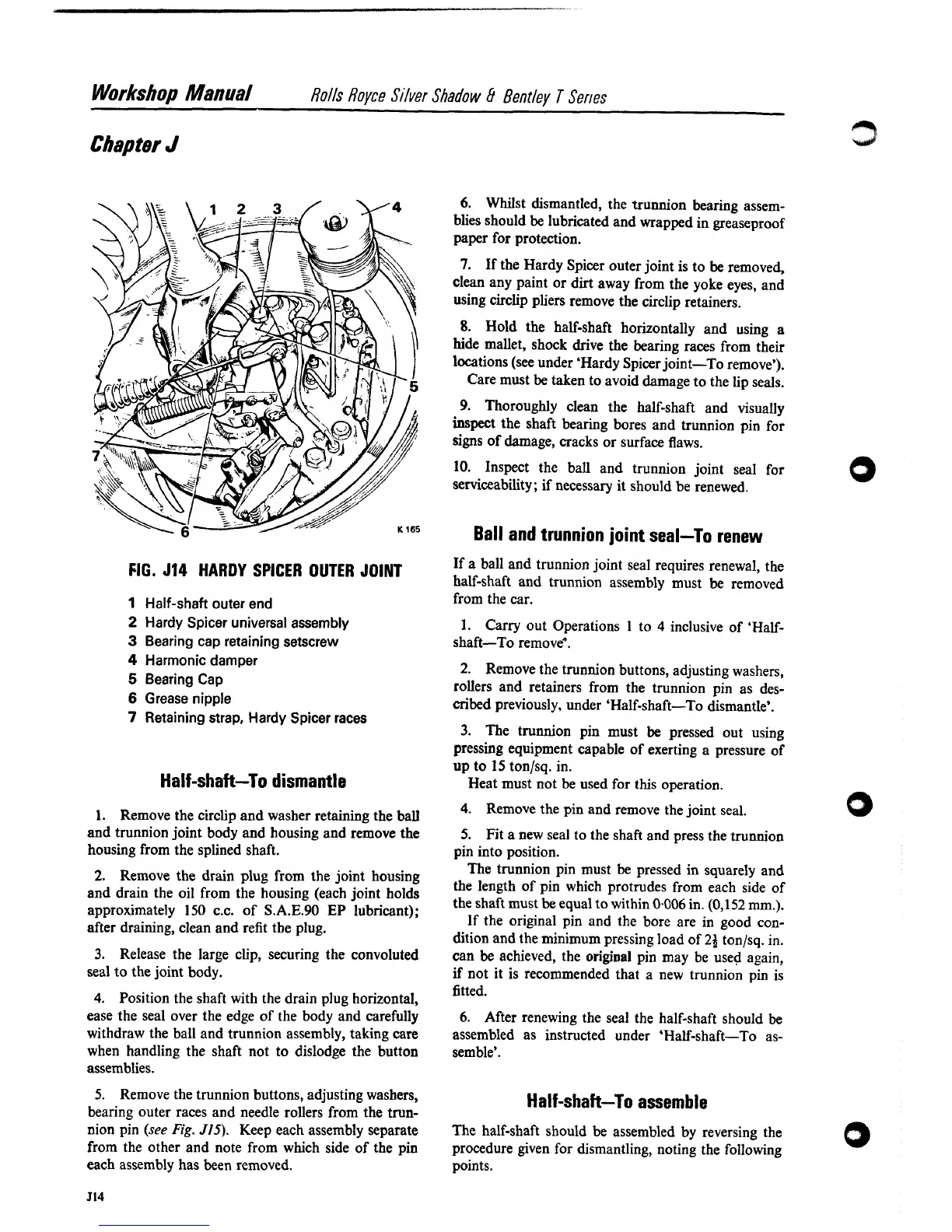

FIG. 514 HARDY SPICER OUTER JOINT

1

Half-shaft outer end

2

Hardy Spicer universal assembly

3

Bearing cap retaining setscrew

4

Harmonic damper

5

Bearing Cap

6

Grease nipple

7

Retaining strap, Hardy Spicer races

Half-shaft-To dismantle

1.

Remove the circlip and washer retaining the ball

and trunnion joint body and housing and remove the

housing from the splined shaft.

2.

Remove the drain plug from the joint housing

and drain the oil from the housing (each joint holds

approximately 150

C.C.

of S.A.E.90 EP lubricant);

after draining, clean and refit tbe plug.

3.

Release the large clip, securing the convoluted

seal to the joint body.

4.

Position the shaft with the drain plug horizontal,

ease the seal over the edge of the body and carefully

withdraw the ball and trunnion assembly, taking care

when handling the shaft not to dislodge the button

assemblies.

5.

Remove the trunnion buttons, adjusting washers,

bearing outer races and needle rollers from the trun-

nion pin

(see

Fig.

J15).

Keep each assembly separate

from the other and note from which side of the pin

each

assembly has been removed.

6.

Whilst dismantled, the trunnion bearing assem-

blies should

be

lubricated and wrapped in greaseproof

paper for protection.

7.

If the Hardy Spicer outer joint is to

be

removed,

clean any paint or dirt away from the yoke eyes, and

using circlip pliers remove the circlip retainers.

8.

Hold the half-shaft horizontally and using

a

hide mallet, shock drive the bearing races from their

locations (see under 'Hardy Spicer joint-To remove').

Care must be taken to avoid damage to the lip seals.

If a ball and trunnion joint seal requires renewal, the

half-shaft and trunnion assembly must be removed

from the car.

1. Carry out Operations

1

to

4

inclusive of 'Half-

shaft-To remove*.

2.

Remove the trunnion buttons, adjusting washers,

rollers and retainers from the trunnion pin as des-

cribed previously, under 'Half-shaft-To dismantle'.

3.

The trunnion pin must

be

pressed out using

pressing equipment capable of exerting a pressure of

up to 15

tonlsq. in.

Heat must not be used for this operation.

4.

Remove the pin and remove the joint seal.

5.

Fit

a

new seal to the shaft and press the trunnion

pin into position.

The trunnion pin must be pressed in squarely and

the length of pin which protrudes from each side of

the shaft must

be

equal to within 0.006 in. (0,152 mm.).

If the original pin and the bore are in good con-

dition and the minimum pressing load of

2a tonlsq. in.

can be achieved, the

original

pin may be used again,

if

not it is recommended that a new trunnion pin is

fitted.

6.

After renewing the seal the half-shaft should be

assembled as instructed under 'Half-shaft-To as-

semble'.

Half-shaft-To assemble

The half-shaft should be assembled by reversing the

procedure given for dismantling, noting the following

points.

Loading...

Loading...