Rolls-Royce Silver Shadow

&

Bentley

I

Series

Workshop

Manual

5. Remove the manometer and connect the choke

stove pipe to the choke housing.

Adjustment of kick diaphragm

1. Hold the choke butterfly closed and check the

clearance between the depression valve operating link

and the choke spindle pin. The clearance should be

0.010 in. (0,254 mm.) (see

Fig.

K27).

The clearance

can be adjusted by fitting washers on the diaphragm

operating rod.

+

Adjustment of kick-gap

(see

Fig.

K28)

The kick-gap should be set to give a reading of 0.050

in. (1,27 mm.) at the bottom of the choke valve.

To obtain this setting, proceed as follows.

1. Slacken the choke depression diaphragm locking

nut. Ensure that the choke is in the 'closed' position,

then

Dress down the depression valve operating lever,

usinga suitable rod, sdthat the depression valve link

rod bears against the end of the 2 B.A. adjusting screw.

2.

The screw should then be adjusted so that a

0.050 in.

(1,27

mm.)

diameter rod or drill can be

inserted between the butterfly housing and the butterfly

valve. Tighten the adjusting screw lock-nut

;

check the

kick-gap and adjust

if

necessary.

3.

Fit the solenoid and shims to the butterfly

housing.

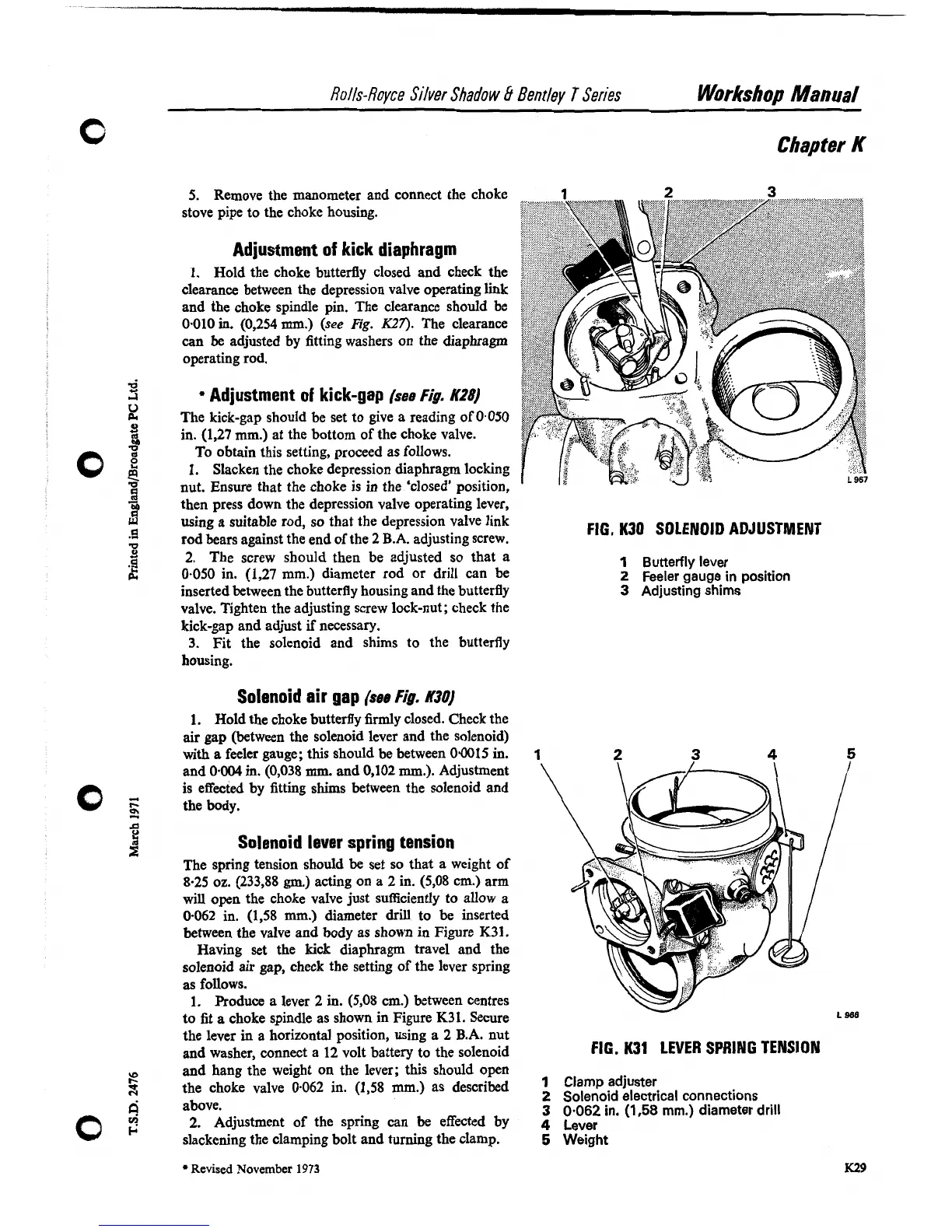

Solenoid air gap

(see

Fig.

K30)

Chapter

K

FIG.

K30 SOLENOID ADJUSTMENT

1

Butterfly lever

2

Feeler gauge in position

3

Adjusting shims

1. Hold the choke butterfly firmly closed. Check the

air gap (between the solenoid lever and the solenoid)

with

a feeler gauge; this should be between 0.0015 in.

1

and 0.004 in. (0,038 mm. and 0,102

rnm.).

Adjustment

is effected by fitting shims between the solenoid and

the body.

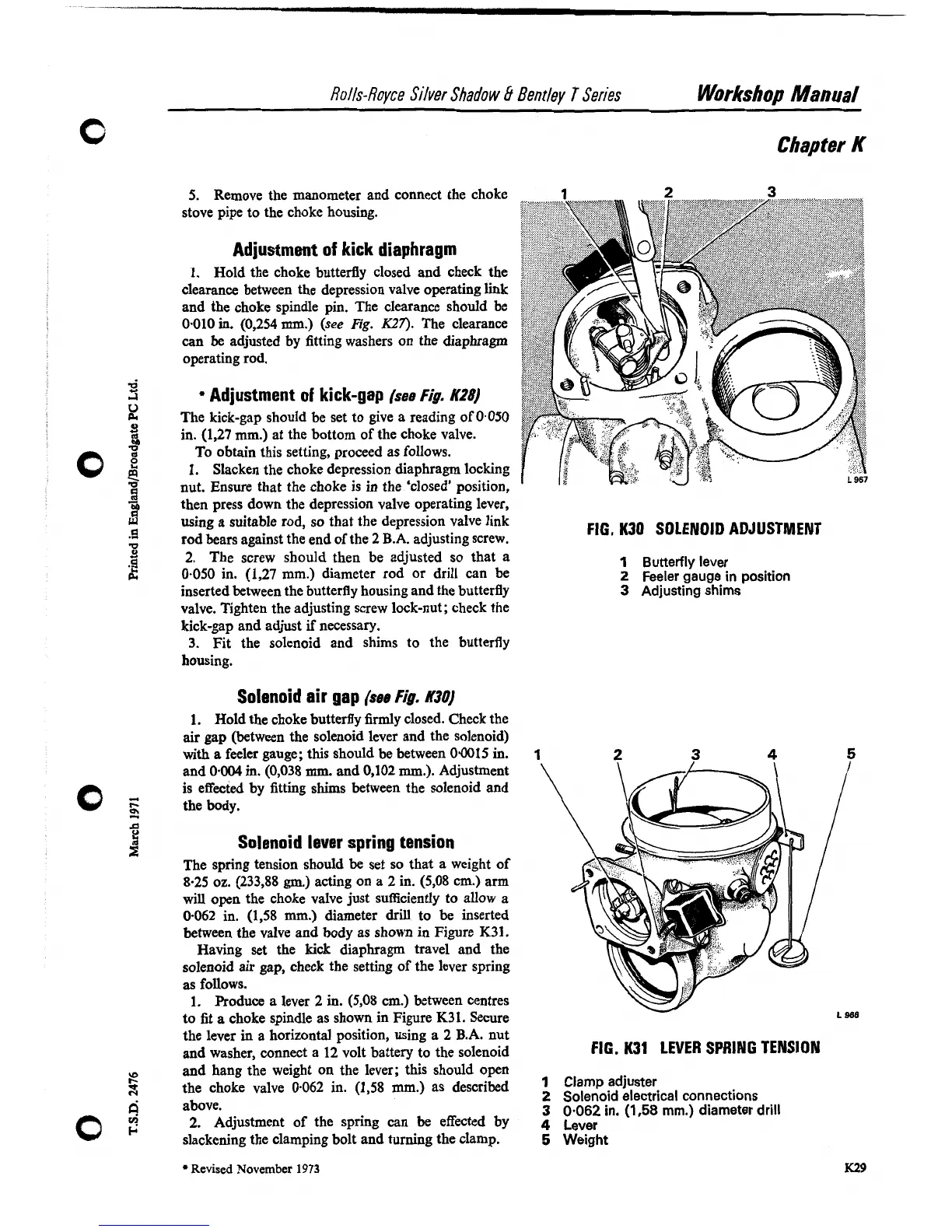

Solenoid lever spring tension

The spring tension should be set so that a weight of

8.25 oz. (233,88

gm.)

acting on a 2 in. (5,08 cm.) arm

will open the choke valve just sufficiently to allow a

0.062 in.

(1,58

mm.)

diameter drill to be inserted

between the valve and body as shown

in

Figure

K31.

Having set the kick diaphragm travel and the

solenoid air gap, check the setting of the lever spring

as follows.

1.

Produce a lever

2

in. (5,08 cm.) between centres

to fit a choke spindle as shown in Figure K31. Secure

-

the lever

in

a horizontal position, using a 2 B.A. nut

and washer, connect a 12 volt battery to the solenoid

FIG.

K31 LEVER SPRING TENSION

and hang the weight on the lever; this should open

the choke valve

0-062 in. (1,58 mm.) as described

Clamp adjuster

above.

2

Solenoid electrical connections

3

0.062

in.

(1,58

mm.) diameter drill

2.

Adjustment of the spring can be effected by

4

Lever

slackening the clamping bolt and turning the clamp.

5

Weight

Revised

November

1973

Loading...

Loading...