Rolls-Rovce Silver Shadow

B

Bentley

T

Series

Workshop

Manual

Chapter

M

are true to centre, then set up the armature between

the centres on a lathe and polish the commutator

with fine glass paper; on no account should emery

cloth or a similar abrasive be used.

5.

If the commutator needs to be skimmed, the

minimum diameter to which it may be reduced is

39,O

mm.

(1.545

in.). After skimming, the

commutator surface should be finally polished with

very fine glass paper, on no account should emery

cloth or a similar abrasive be used.

The insulation segments on the commutator must

not be undercut.

Brushes-To remove

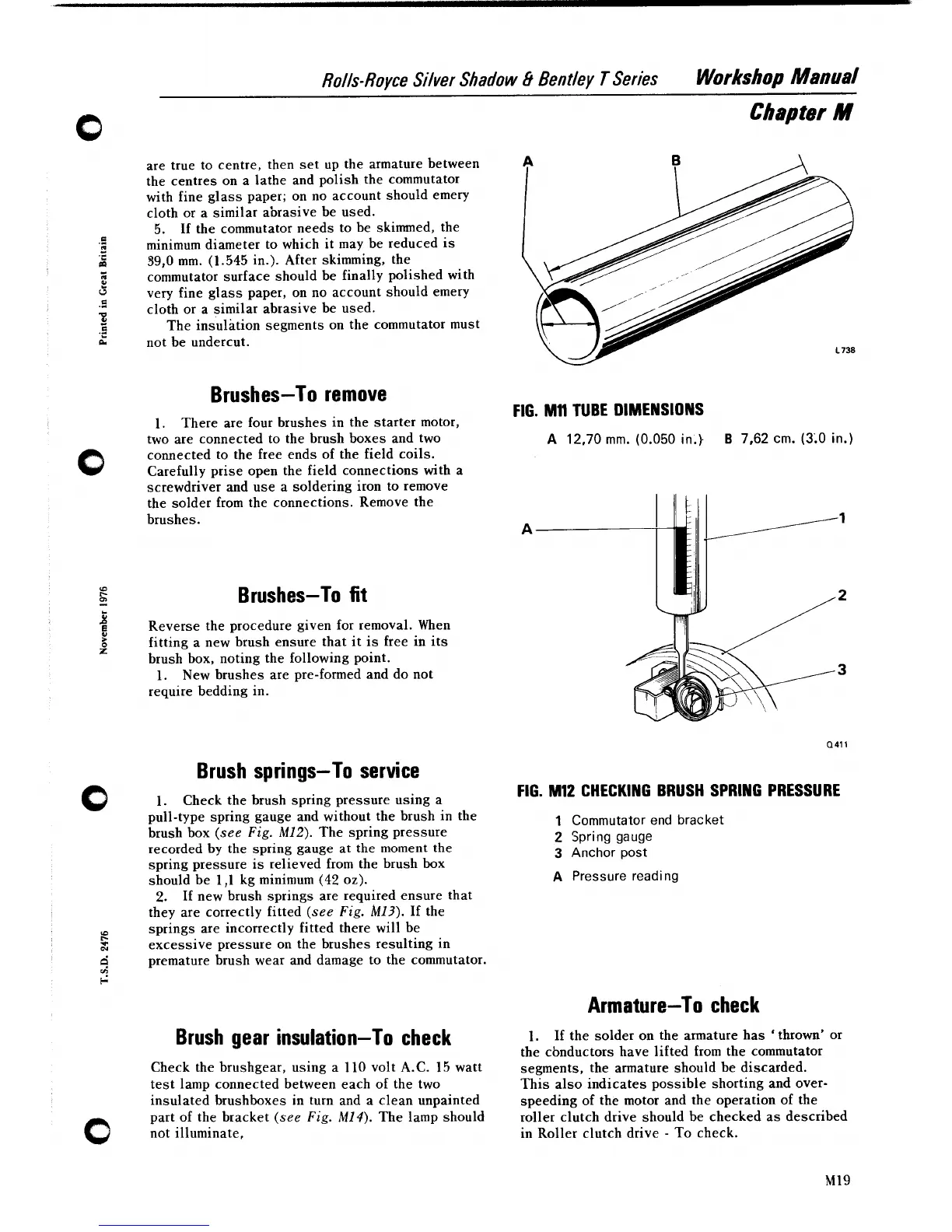

FIG.

Mll

TUBE DIMENSIONS

1.

There are four brushes in the starter motor,

two are connected to the brush boxes and two

A

12,70mm.(O.O50in.)~

B

7,62cm.(3;0in.)

connected to the free ends of the field coils.

Carefully prise open the field connections with a

screwdriver and use a soldering iron to remove

the solder from the connections. Remove the

brushes.

A

Brushes-To

fit

Reverse the procedure given for removal. When

fitting a new brush ensure that it is free in its

brush box, noting the following point.

1.

New brushes are pre-formed and do not

require bedding in.

Brush springs-To service

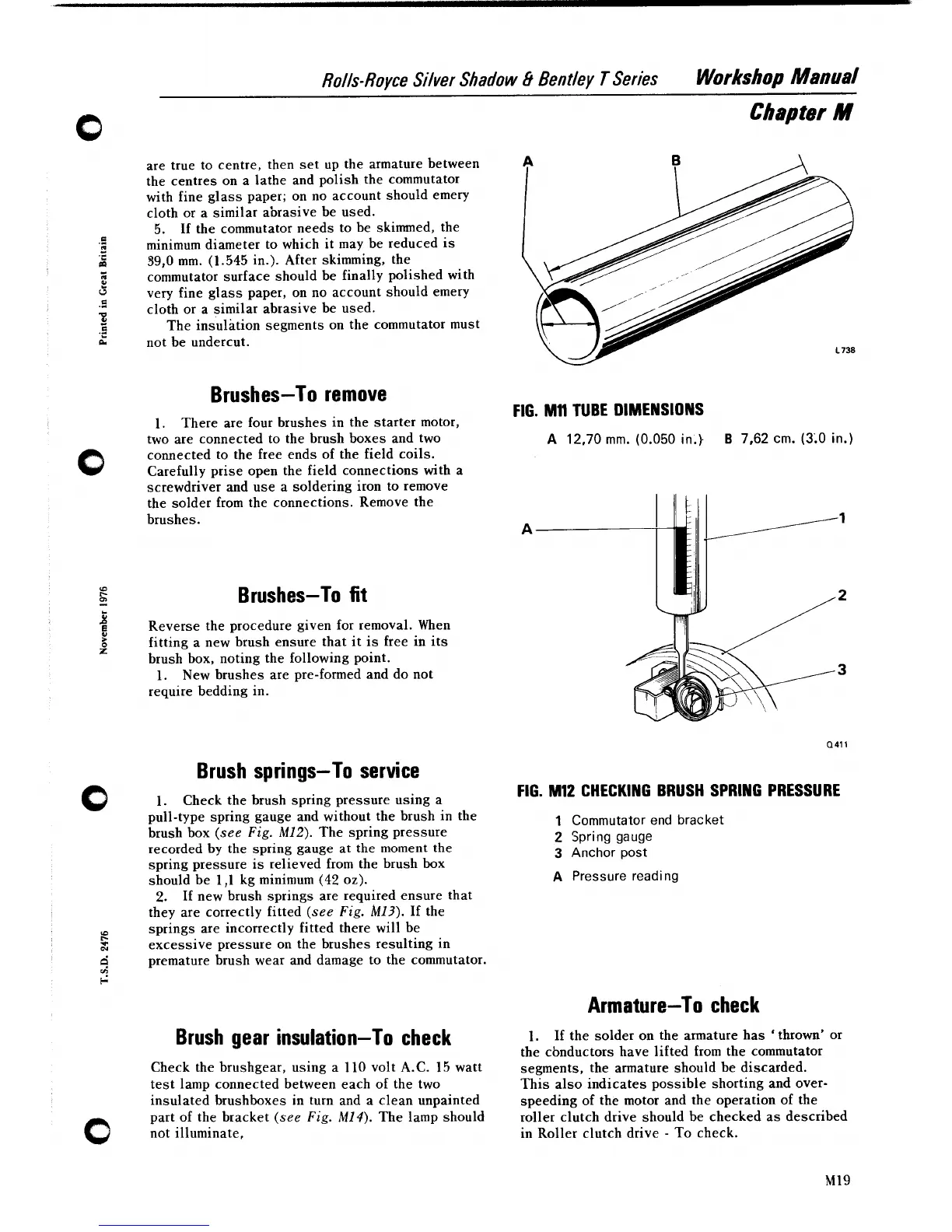

1.

Check the brush spring pressure using a

pull-type spring gauge and without the brush in the

brush box

(see

Fig.

M12).

The spring pressure

recorded

by

the spring gauge at the moment the

spring pressure is relieved from the brush box

should be

1

,l

kg minimum

(42

oz).

2.

If new brush springs are required ensure that

they are correctly fitted

(see

Fig.

hfl3).

If the

springs are incorrectly fitted there will be

excessive pressure on the brushes resulting in

premature brush wear and damage to the commutator.

Brush gear insulation-To check

Check the brushgear, using a

110

volt A.C.

15

watt

test lamp connected between each of the two

insulated brushboxes in turn and a clean unpainted

part of the bracket

(see

Fig.

M14).

The lamp should

not illuminate,

FIG.

MI2

CHECKING BRUSH SPRING PRESSURE

1

Commutator end bracket

2

Spring gauge

3

Anchor post

A

Pressure reading

Armature-To check

1.

If the solder on the armature has 'thrown' or

the cbnductors have lifted from the commutator

segments, the armature should be discarded.

This also indicates possible shorting and

over-

speeding of the motor and the operation of the

roller clutch drive should be checked as described

in Roller clutch drive

-

To check.

Loading...

Loading...