Rolls-Royce Silver

Shadow

B

Bentley

T

Series

Workshop

Manus/

special hydraulic ram

(RH

8017) and special extrac-

tor beam (RH 8033).

3. Remove the pinion oil seal and the oil

flinger

fitted behind it.

4.

Place the housing in a press

with

the

pinion

gear downward and the housing lower end

firmly

supported and carefully press the pinion out of the

housing.

5.

Collect the adjusting washers from the pinion

shank and the taper roller bearing from the housing.

6.

If new taper roller bearings are to be fitted, the

outer tracks must be removed from the housing,

using a soft drift and a hammer, taking

care

to avoid

damage to the bearing locating bores.

7.

The large roller bearing should be removed from

beneath the pinion head using a press and the special

tool

(RH

7863).

8.

Wash all parts thoroughly in paraffin and

dry

with compressed air.

9. Inspect all parts for

serviceability, and any

showing damage, pitting or excessive wear should

be

renewed.

Pinion housing--To

assemble

Prepare the washed and inspected parts, complete

with any new or replacement parts for assembly,

as

follows.

1. Lightly lubricate all components paying parti-

cular attention to the roller bearing races.

2.

If

new bearings are being fitted, carefully press

the outer tracks into the housing and the large roller

bearing on to the pinion, ensuring that the bearings

are square and right up to their abutment faces.

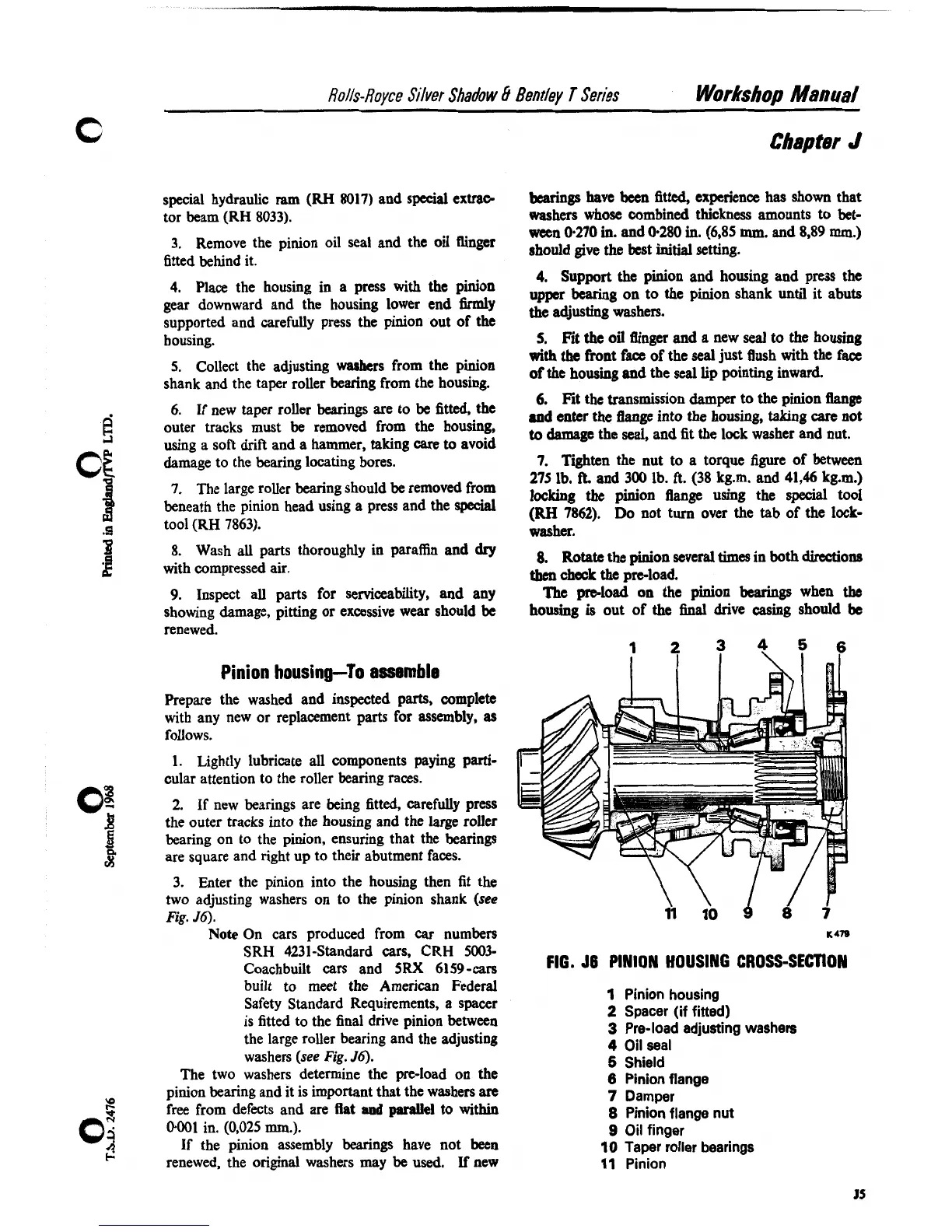

3.

Enter the pinion into the housing then fit the

two adjusting washers on to the pinion shank (see

Fig.

56).

Note On cars produced from

car

numbers

SRH 4231-Standard cars, CRH

5003-

Coachbuilt cars and 5RX 6159-cars

built to meet the American Federal

Safety Standard Requirements, a spacer

is fitted to the final drive pinion between

the large roller bearing and the adjusting

washers

(see

Fig.

56).

The two washers determine the pre-load on the

pinion bearing and it is important that the washers

are

free from defects and are

flat

and

parallel

to within

0.001 in. (0,025

mm.).

If

the pinion assembly bearings have not been

renewed, the original washers may be used.

If

new

Chapter

J

bearings

have

been

fitted, experience

has

shown that

washers whose combined thickness amounts to bet-

ween

0-270 in. and 0.280 in. (6,85

mm.

and 8,89

mm.)

should

give

the best initial setting.

4.

Support the pinion and housing and pms the

upper bearing on to the pinion shank until it abuts

the adjusting washers.

5.

Fit

the

oil flinger and a new

seal

to

the

housing

with

the

Front fact of the seal just flush with the fact

of the housing

and

the seal lip pointing inward.

6.

Fit the transmission damper to the pinion

flange

md

enter

the

huge into the housing, taking

care

not

to

damage

the

seal,

and fit the lock washer and nut.

7. Tighten the nut to a torque figure of between

275 lb.

R.

and 300 lb.

ft.

(38 kg.m. and

41,46

kg.m.)

locking the pinion

flange

using the special tool

(RH

7862). Do not turn over the tab of the lock-

washer.

8.

Rotate the pinion several

times

in both directions

then

check

the

pre-load

Thc

pload on the pinion

bearings

when the

housing

is

out of

the

final

drive casing should

be

FIG.

56

PINION HOUSING CROSS-SECTION

1

Pinion housing

2

Spacer (if fitted)

3

Pre-load adjusting washers

4

Oil seal

5

Shield

6

Pinion flange

7

Damper

8

Pinion flange nut

9

Oil finger

10

Taper roller bearings

11

Pinion

Loading...

Loading...