Workshop

Manual

Rolls Rovce Silver

Shadow

8

Bentlev

T

Series

Chapter

J

15. Fit the two adjusting washers behind the crown

wheel bearing and fit the left-hand side housing.

Progressively tighten the housing nuts whilst rocking

the crown wheel back and forth to ensure that there

is still backlash between the gears.

16. Mount a dial test indicator on the final drive

casing with the indicator pad on the flank of a crown

wheel tooth.

17. Zero the indicator and rock the crown wheel

back and forth noting the backlash.

18. The backlash should be checked at twelve posi-

tions around the crown wheel and an average reading

taken. This figure should conform to the backlash

figure etched on the crown wheel.

19. If it does not conform, the thickness of the

washers behind the crown wheel bearing must be

varied to obtain the correct reading.

These washers are available in a range from

0.1 11

in.

to 0.129 in. (2,819 mm. to 3,27

mm.)

in

increments

of

0.002 in. (0,050 mm.) and it can be assumed that

0.001 in. (0,025

mm.)

variation in the thickness of the

,,,,

adjusting washer

will

make a difference of 0.001 in.

(0,025

mm.)

to the backlash.

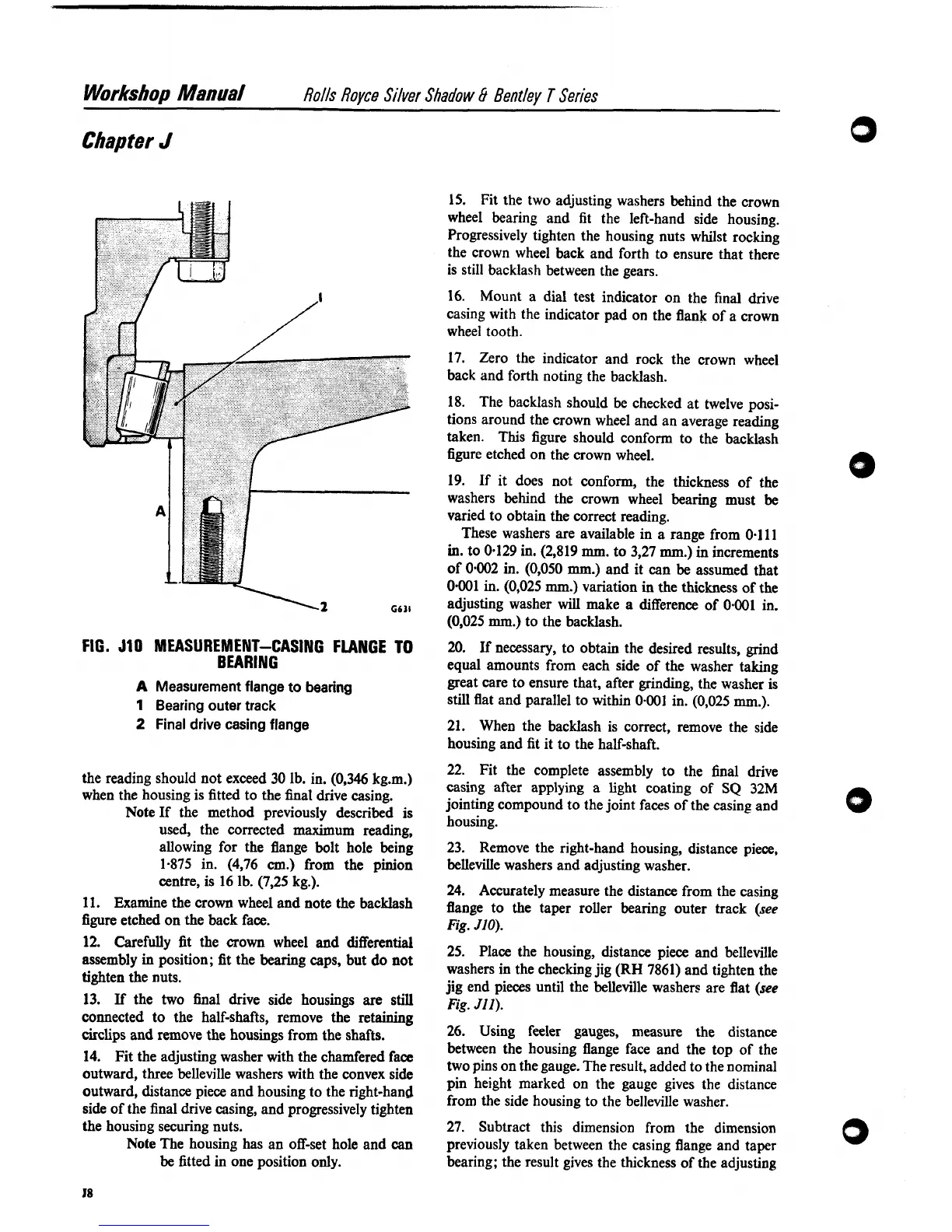

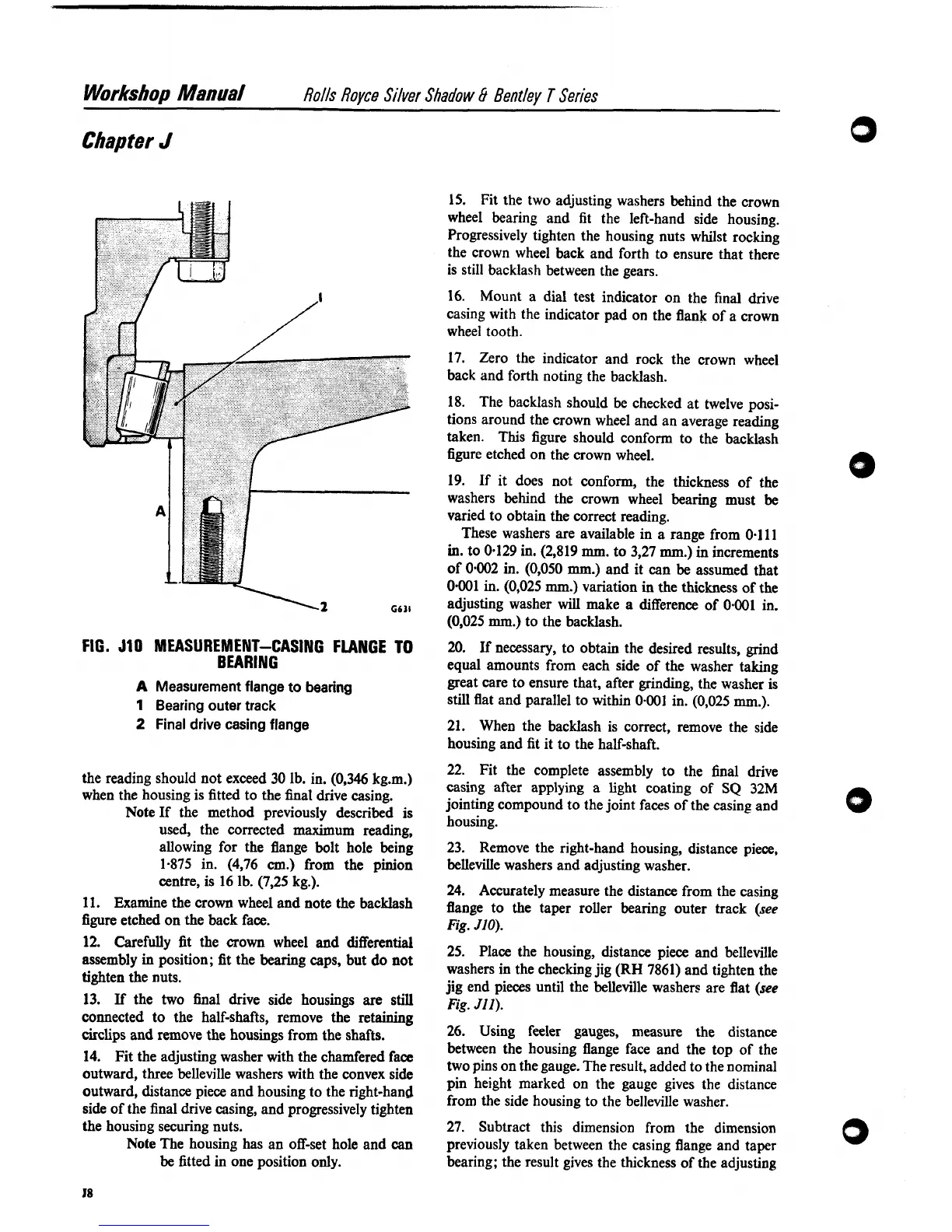

FIG.

J10

MEASUREMENT-CASING FLANGE

TO

20.

If

necessary, to obtain the desired results, grind

BEARING

equal amounts from each side of the washer taking

A

Measurement flange to bearing

great care to ensure that, after grinding, the washer is

1

Bearing outer track

still flat and parallel to within

0.001 in. (0,025

mm.).

2

Final drive casing flange 21. When the backlash is correct, remove the side

housing and fit it to the half-shaft.

22. Fit the complete assembly to the final drive

the reading should not exceed 30 lb. in. (0,346 kg.m.1

Easing

after

applying

a

Bght

coating

of

SQ

32M

when the housing

is

fitted to the final drive casing.

jointing compound to the joint faces of the casing and

Note

If

the method previously described is

used, the corrected maximum reading,

allowing for the flange bolt hole

being

23. Remove the right-hand housing, distance piece,

1.875 in. (4,76

cm.)

from the pinion belleville washers and adjusting washer.

centre, is

16

lb. (7,25 kg.).

24.

Accurately measure the distance from the casing

11. Examine the crown wheel and note the backlash

flange to the taper roller bearing outer track (see

figure etched on the back face.

Fig.

JIO).

-

l2

fit

the

crown

and

25. Place the housing, distance piece and belleville

assembly

in

position; fit the bearing caps, but do not

tighten the nuts.

washers in the checking jig

(RH

7861) and tighten the

jig end pieces until the belleville washers are flat (see

13.

If

the two final drive side housings are still

fi.

~11).

connected to the half-shafts, remove the retaining

circlips and remove the housings from the shafts. 26. Using feeler gauges, measure the distance

between the housing flange face and the top of the

14.

Fit the adjusting washer with the chamfered face

two

pins

on

the

gauge.

The

result,

added

to

the

outward, three belleville washers with the convex side

pin

height

on

the

gauge

gives

the

distance

outward, distance piece and housing to the right-hand

side of the final drive casing, and progressively tighten

from the side housing to the belleville washer.

the housing securing nuts. 27. Subtract this dimension from the dimension

Note The housing has an off-set hole and

can

previously taken between the casing flange and taper

be fitted in one position only. bearing; the result gives the thickness of the adjusting

Loading...

Loading...