Workshop

Manual

Rolls Royce Silver Shadow

d

Bentley

T

Series

Chapter

#

7.

Remove the lower steering column assembly (see

'Lower steering column assembly-To remove').

8. Support the engine with either a sling or a jack

and wooden pad.

9. Remove the two nuts and washers securing the

engine front mounting.

10. Remove the nuts and bolts securing the steering

box pipes to the engine front cross-member.

11. Remove the split pin and nut from the pendulum

lever joint on the steering cross-beam then, using

extractor

(RH

8100), partially extract the ball pin

from the lever.

12. Remove the nut securing the pendulum lever to

the rocking shaft; remove pendulum lever using ex-

tractor (RH 8023).

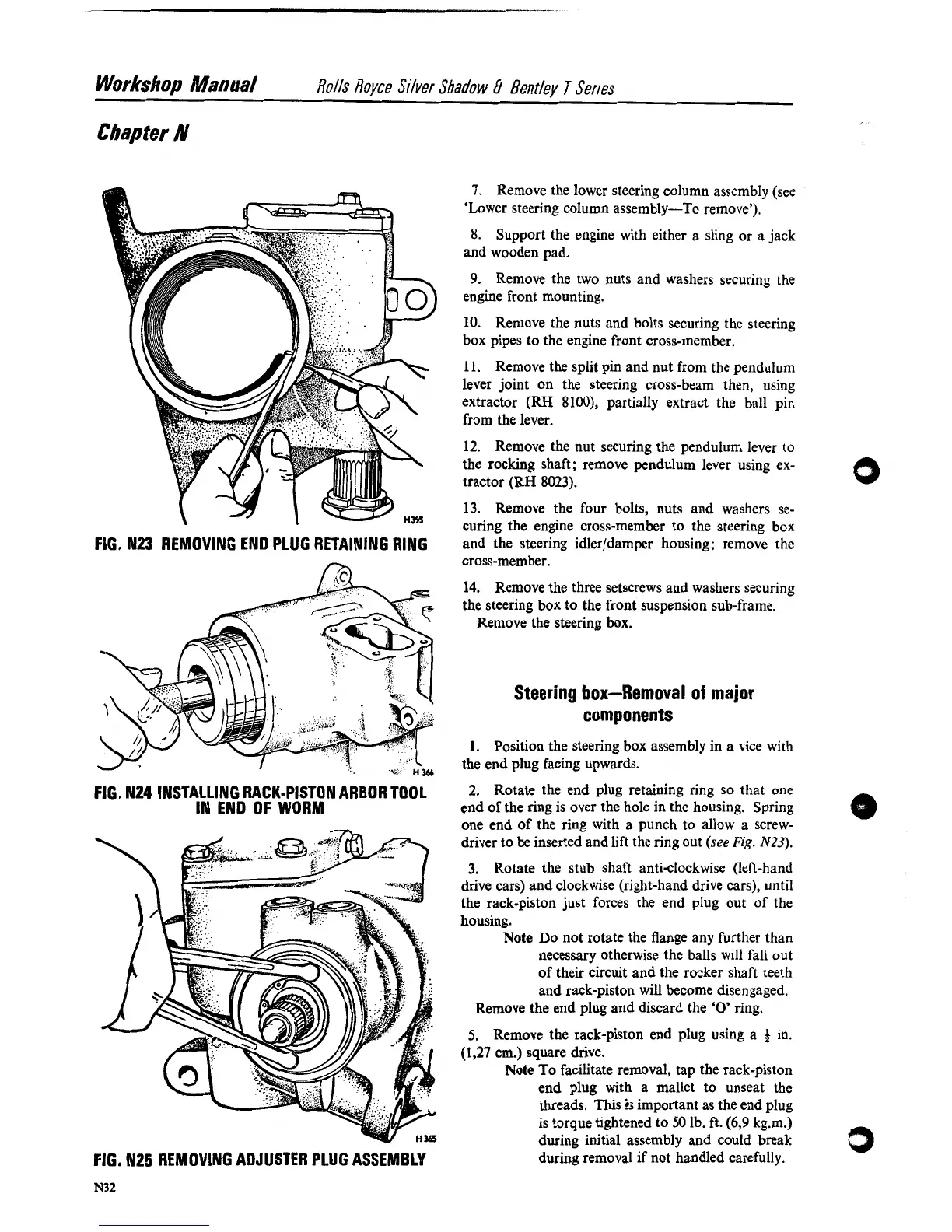

FIG. N23 REMOVING END PLUG RETAINING RING

FIG.

N24

INSTALLING RACK-PISTON ARBOR TOOL

IN END OF WORM

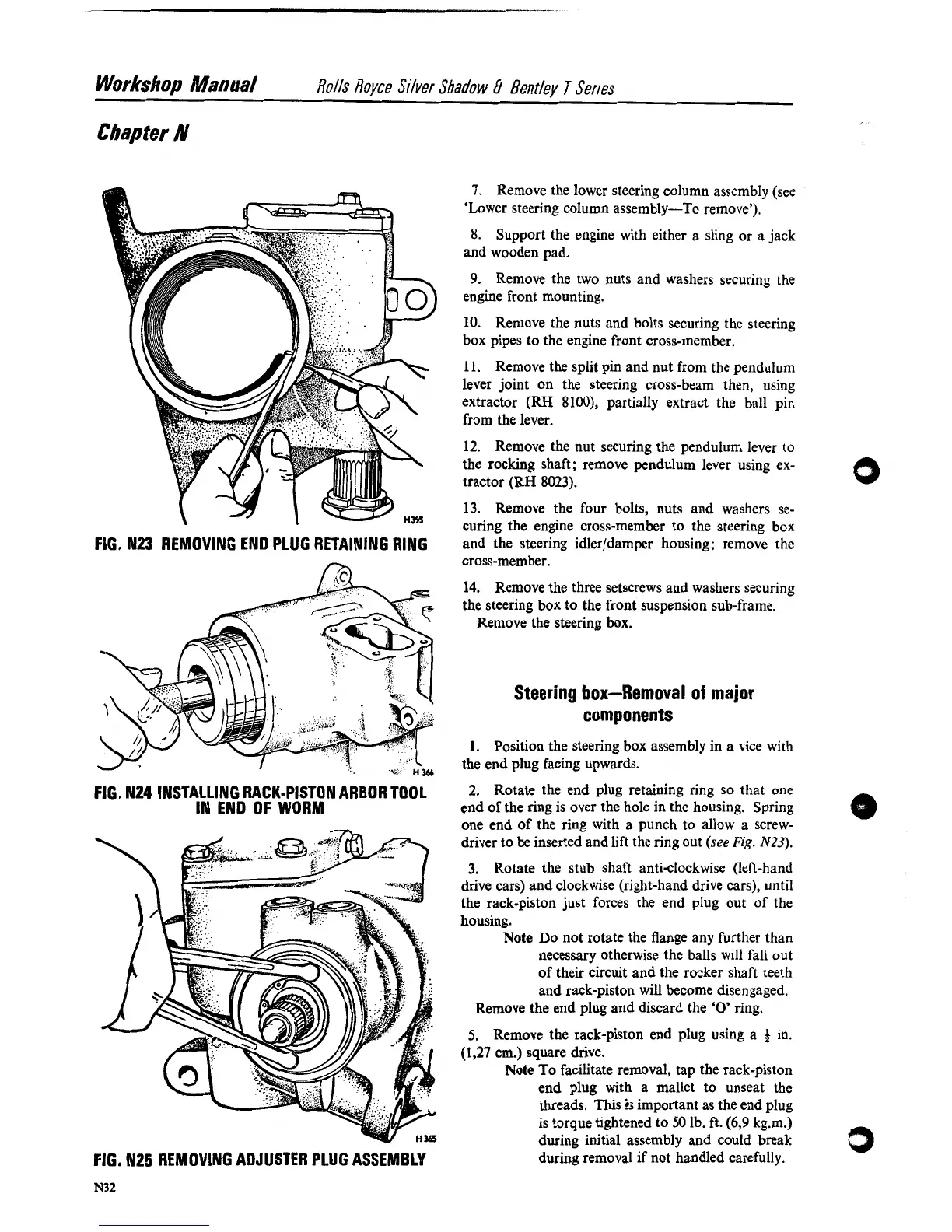

FIG. N25 REMOVING ADJUSTER PLUG ASSEMBLY

N32

13. Remove the four bolts, nuts and washers se-

curing the engine cross-member to the steering box

and the steering

idlerldamper housing; remove the

cross-member.

14. Remove the three setscrews and washers securing

the steering box to the front suspension sub-frame.

Remove the steering box.

Steering box-Removal of major

components

1. Position the steering box assembly in a vice with

the end plug facing upwards.

2.

Rotate the end plug retaining ring so that

one

end of the ring

is

over the hole in the housing. Spring

one end of the ring with a punch to allow a screw-

driver to be inserted and lift the ring out

(see

Fig.

N23).

3. Rotate the stub shaft anti-clockwise (left-hand

drive cars) and clockwise (right-hand drive cars), until

the rack-piston just forces the end plug out of the

housing.

Note

Do not rotate the flange any further than

necessary otherwise the balls will fall out

of their circuit and the rocker shaft teeth

and rack-piston will become disengaged.

Remove the end plug and discard the

'0'

ring.

5. Remove the rack-piston end plug using a

4

in.

(1,27

cm.)

square drive.

Note

To

facilitate removal, tap the rack-piston

end plug with a mallet to unseat the

threads. This

is

important as the end plug

is torque tightened to 50 lb. ft.

(6,9 kg.m.)

during initial assembly and could break

during removal if not handled carefully.

Loading...

Loading...