Rolls-R~i.;"e Si/ver Shadow

&

Bentley

T

Series

Mhk~h0p

Manual

If it is necessary to renew the large taper roller

bearings, they should be pressed off the differential

housing and end

cap.

6.

Wash all parts thoroughly and

dry

with

com-

pressed

air.

7.

Thoroughly inspect

all

components for wear

or

damage marks and renew any defective items. The

adjuat&g washers, excluding the dished thrust washers

behind the bevel

gears,

should

all

be

flat and parallel.

Ensure that all bearing surfaces and bores are

free

from damage, pitting or burrs and that all gears are

free

from damage or excessive wear.

Crown wheel and differential assembly-

To

assemble

Repare the washed and inspected parts, complete

with

any new or replacement parts, for assembly

which is a careful reversal of the dismantling pro-

cedure as follows

:

1.

If

new taper roller bearings are to be fitted, they

must be pressed squarely on to the diameters on the

end of the differential housing and end cap noting

that, the larger of the two bearings is fitted to the

housing and that both bearings are fitted correctly

against their abutment faces

(see

Fig.

J9).

2.

If

the adjusting washer positions are not known

or

if

new pieces are being fitted the following precedure

is

recommended for assembling the differential hous-

ing as described in Operations

3

to

6

inclusive.

3.

Fit the sphed bevel pinion into the end of the

08

differential housing without an adjusting washer

J

behind the head.

a

Chapter

J

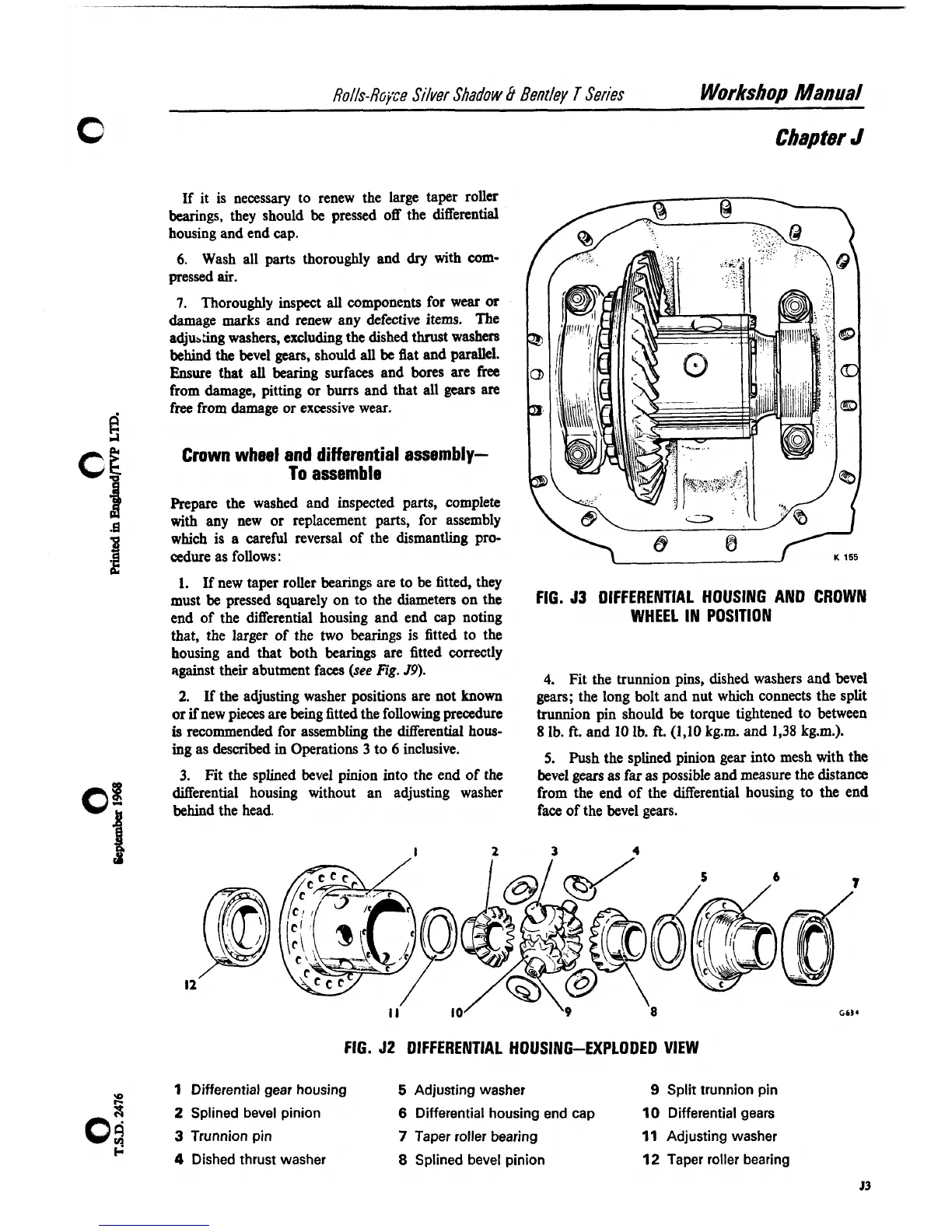

FIG.

53

OIFFERENTIAL HOUSING AND CROWN

WHEEL IN POSITION

4.

Fit the trunnion pins, dished washers and bevel

gears; the long bolt and nut which connects the split

trunnion pin should

be

torque tightened to between

8

lb. ft. and

10

Ib.

ft.

(410

kg.m. and 1,38 kg-m.).

5.

Push the splined pinion gear into mesh with the

bevel gears

as

far as possible and measure the distance

from the end of the differential housing to the end

face

of the bevel gears.

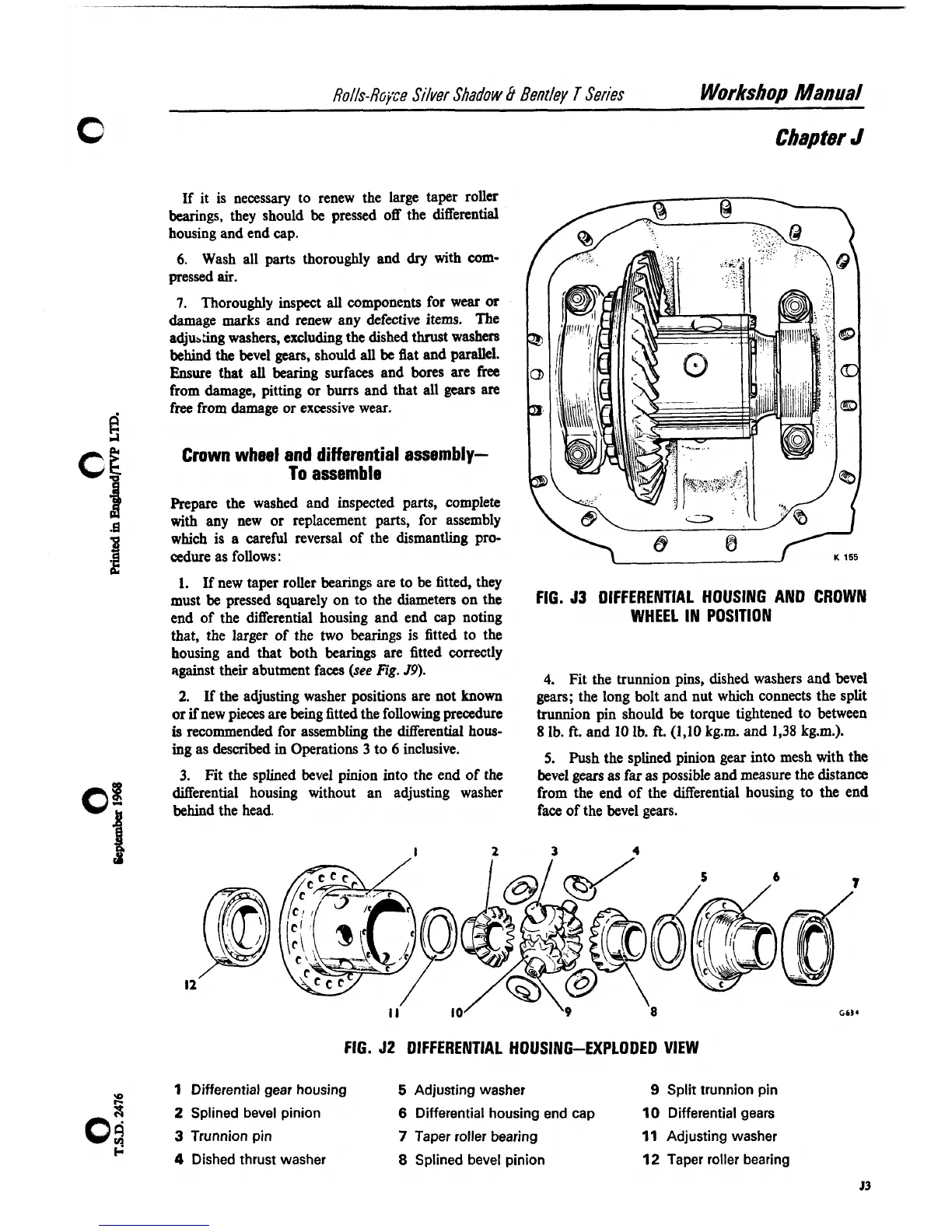

FIG.

52

DIFFERENTIAL HOUSING-EXPLODED VIEW

1

Differential gear housing

5

Adjusting washer

9

Split trunnion pin

2

Splined bevel pinion

6

Differential housing end cap

10

Differential gears

3

Trunnion pin

7

Taper roller bearing

11

Adjusting washer

4

Dished thrust washer

8

Splined bevel pinion

12

Taper roller bearing

Loading...

Loading...