Workshop

Manual

Rolls- Royce Silver Shadow

B

Bentley

T

Series

Chapter

M

6.

Start the engine and run the genelator at

1500

r.p.m.

7.

Using

'

Lucas' tool (543-817-42), turn the

voltage adjustment cam until the correct setting is

obtained (turning the tool clockwise raises the

setting and turning the tool anti-clockwise lowers

the setting).

8.

Stop and then re-start the engine and repeat the

test to check the regulator settings.

9.

Fit the original connections and fit the control

box cover.

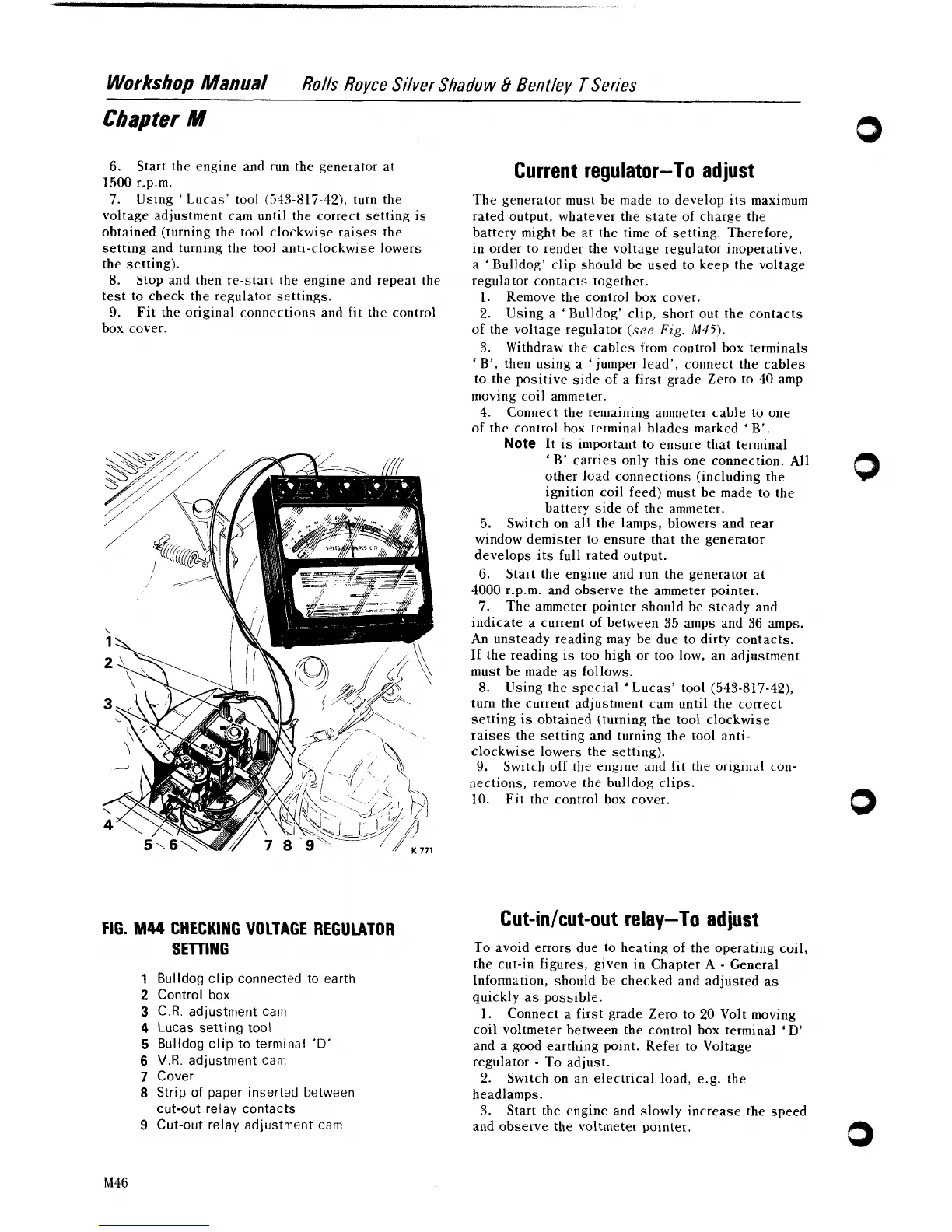

FIG.

M44

CHECKING VOLTAGE REGULATOR

SETTING

1

Bulldog clip connected to earth

2

Control box

3

C.R. adjustment cam

4

Lucas setting tool

5

Bulldog clip to terminal

'D'

6

V.R.

adjustment can1

7

Cover

8

Strip of paper inserted between

cut-out relay contacts

9

Cut-out relay adjustment cam

Current regulator-To

ad

just

The generator must be made to develop its maximum

rated output, whatever the state of charge the

battery might be at the time of setting. Therefore,

in order to render the voltage regulator inoperative,

a

'

Bulldog' clip should be used to keep the voltage

regulator contacts together.

1.

Remove the control box cover.

2.

Using a 'Bulldog' clip, short out the contacts

of the voltage regulator

(see

Fig.

M45).

3. Withdraw the cables trom control box terminals

'

B', then using a 'jumper lead', connect the cables

to the positive side of a first grade Zero to 40 amp

moving coil ammeter.

4.

Connect the remaining ammeter cable to one

of the control box terminal blades marked

'

B'.

Note

It

is important to ensure that terminal

'

B' carries only this one connection. All

other load connections (including the

ignition coil feed) must be made to the

battery side of the ammeter.

5.

Switch on all the lamps, blowers and rear

window demister to ensure that the generator

develops its full rated output.

6.

Start the engine and run the generator at

4000

r.p.m. and observe the ammeter pointer.

7.

The ammeter pointer should be steady and

indicate a current of between 35 amps and 36 amps.

An unsteady reading may be due to dirty contacts.

If

the reading is too high or too low, an adjustment

must be made as follows.

8.

Using the special 'Lucas' tool (543-817-42),

turn the current adjustment cam until the correct

setting is obtained (turning the tool clockwise

raises the setting and turning the tool

anti-

clockwise lowers the setting).

9.

Switch off the engine and fit the original con-

nections, remove the bulldog clips.

10.

Fit the control box cover.

Cut-inlcut-out relay-To adjust

To avoid errors due to heating of the operating coil,

the cut-in figures, given in Chapter

A

-

General

Inform~tion, should be checked and adjusted as

quickly as possible.

1. Connect a first grade Zero to 20 Volt moving

coil voltmeter between the control box terminal

'

D'

and a good earthing point. Refer to Voltage

regulator

-

To adjust.

2.

Switch on an electrical load,

e.g. the

headlamps.

3.

Start the engine and slowly increase the speed

and observe the voltmeter pointer.

Loading...

Loading...