Workshop

Manual

Rolls- Royce Silver Shadow

8

Bentley

T

Series

Chapter

Q

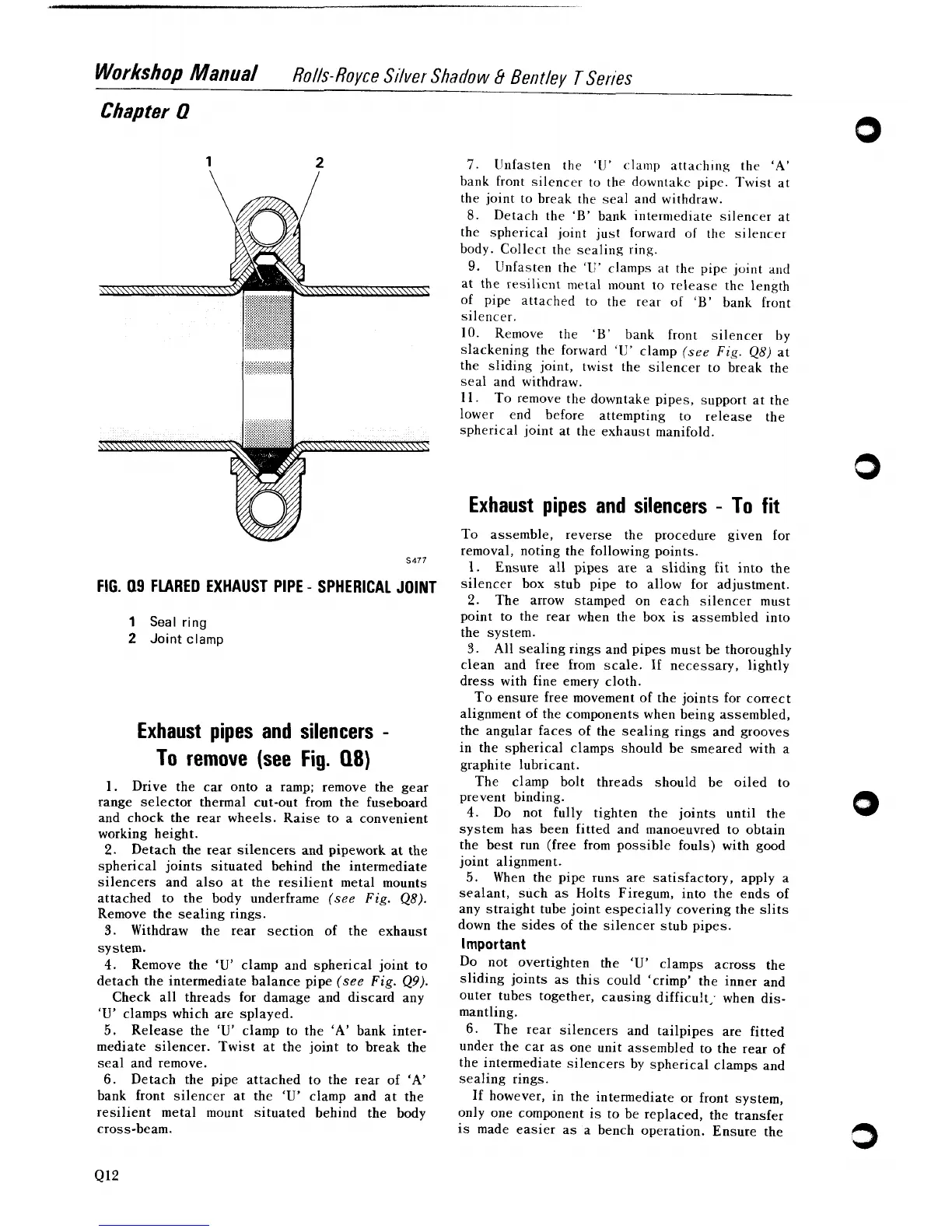

FIG.

09

FLARED EXHAUST PIPE

-

SPHERICAL JOINT

1

Seal

ring

2

Joint

clamp

Exhaust pipes and silencers

-

To remove (see

Fig.

Q8)

1.

Drive the car onto a ramp; remove the gear

range selector thermal cut-out from the fuseboard

and chock the rear wheels. Raise to a convenient

working height.

2.

Detach the rear silencers and pipework at the

spherical joints situated behind the intermediate

silencers and also at the resilient metal mounts

attached to the body underframe

(see

Fig.

48).

Remove the sealing rings.

3.

Withdraw the rear section of the exhaust

system.

4.

Remove the

'U'

clamp and spherical joint to

detach the intermediate balance pipe

(see

Fig.

49).

Check all threads for damage and discard any

'U'

clamps which are splayed.

5.

Release the

'U'

clamp to the

'A'

bank inter-

mediate silencer. Twist at the joint to break the

seal and remove.

6.

Detach the pipe attached to the rear of

'A'

bank front silencer at the

'U'

clamp and at the

resilient metal mount situated behind the body

cross-beam.

7.

llnfasten the

'IJ'

clamp attaching the 'A'

bank front silencer to the

downtake pipe. Twist at

the joint to break the seal and withdraw.

8.

Detach the

'B'

bank intermediate silencer at

the spherical joint

just

forward of the silencer

body. Collect the sealing ring.

9.

Unfasten the 'li' clamps at the pipe joint and

at the

rrsilic~lt metal mount to release the length

of pipe attached to the rear of

'B'

bank front

silencer.

10. Remove the

'B'

bank front silencer by

slackening the forward

'U'

clamp

(see

Fig.

48)

at

the sliding joint, twist the silencer to break the

seal and withdraw.

11. To remove the

downtake pipes, support at the

lower end before attempting to release the

spherical joint at the exhaust manifold.

Exhaust pipes and silencers

-

To fit

To assemble, reverse the procedure given for

removal, noting the following points.

1.

Ensure all pipes are a sliding fit into the

silencer

box stub pipe to allow for adjustment.

2.

The arrow stamped on each silencer must

point to the rear when the box is assembled into

the system.

3.

All sealing rings and pipes must be thoroughly

clean and free from scale. If necessary, lightly

dress with fine emery cloth.

To ensure free movement of the joints for correct

alignment of the components when being assembled,

the angular faces of the sealing rings and grooves

in the spherical clamps should be smeared with a

graphite lubricant.

The clamp bolt threads should be oiled to

prevent binding.

4.

Do not fully tighten the joints until the

system has been fitted and manoeuvred to obtain

the best run (free from possible fouls) with good

joint alignment.

5.

When the pipe runs are satisfactory, apply a

sealant, such as Holts

Firegum, into the ends of

any straight tube joint especially covering the slits

down the sides of the silencer stub pipes.

Important

Do not overtighten the

'U'

clamps across the

sliding joints as this could 'crimp' the inner and

outer tubes together, causing

difficu!t; when dis-

mantling.

6.

The rear silencers and tailpipes are fitted

under the car as one unit assembled to the rear of

the intermediate silencers by spherical clamps and

sealing rings.

If

however, in the intermediate or front system,

only one component is to be replaced, the transfer

is made easier as a bench operation. Ensure the

Loading...

Loading...