Workshop

Manual

Rolls-Royce Silver Shadow

I)

Bentley

T

Series

Chapter

M

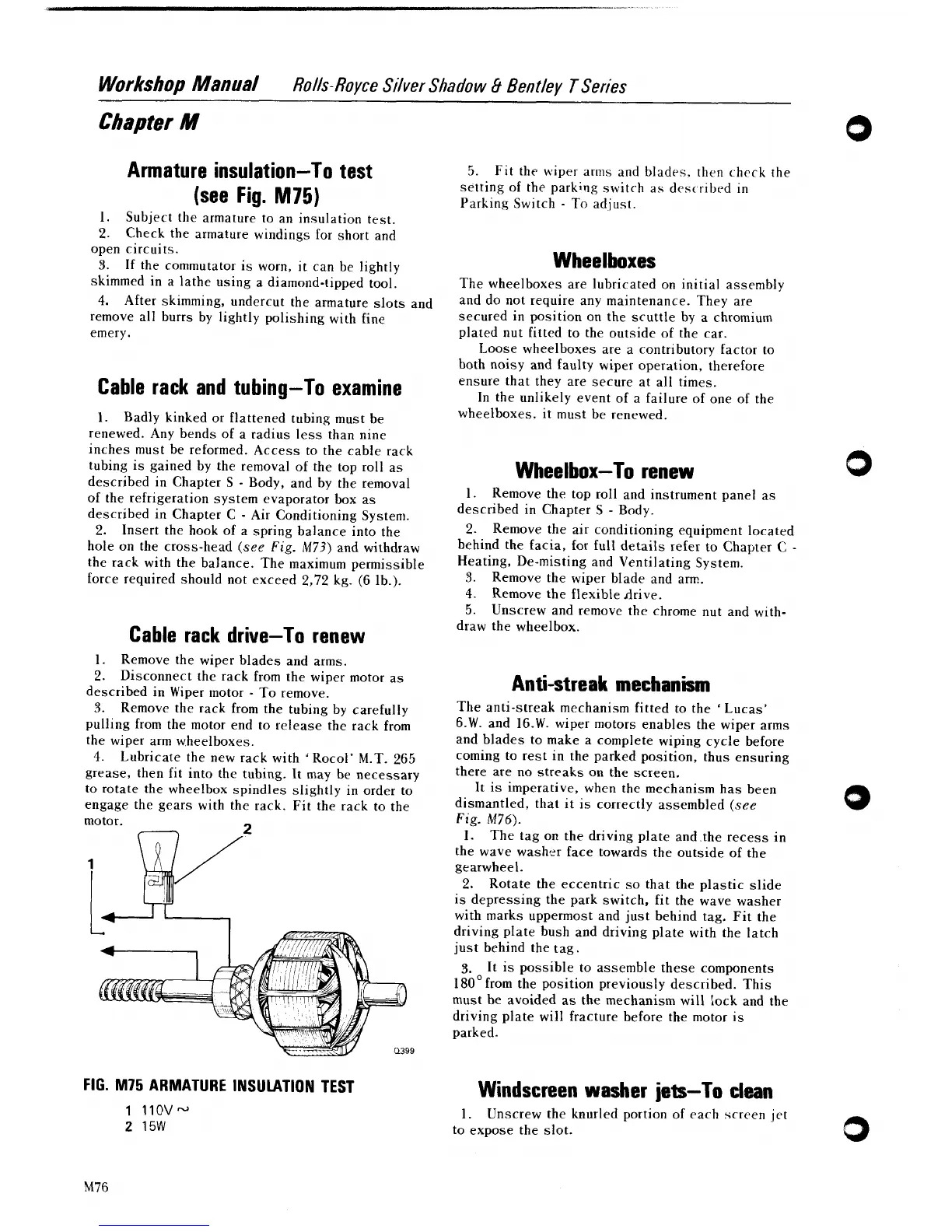

Armature insulation-TO test

5.

Fit the wiper arms and blades. then

cheek

the

(see Fig.

M75)

1.

Subject the armature to an insulation test.

setting of the parking switch

as

desc rlt)~d in

Parking Switch

-

To adjust.

2.

Check the armature windings for short and

open circuits.

S.

If

the commutator is worn, it can be lightly

W

heelboxes

skimmed in a lathe using a diamond-tipped tool.

The wheelboxes are lubricated on initial

assembly

4.

After skimming, undercut the armature and and do not require any maintenance. They are

remove all burrs by lightly polishing with

fine

secured in position on the scuttle by a chromium

emery.

plated nut fitted to the outside of the car.

Loose wheelboxes are a contributory factor to

both noisy and faulty wiper operation, therefore

Cable rack and tubing-To examine

ensure that they are secure at all times.

In the unlikely event of a failure of one of the

1.

Badly kinked or flattened tubing must be

wheelboxes. it must be renewed.

renewed. Any bends of a radius less than nine

inches must be reformed. Access to the cable rack

tubing is gained by the removal of the top roll as

described in Chapter S

-

Body, and by the removal

of the refrigeration system evaporator box as

described in Chapter

C

-

Air Conditioning System.

2.

Insert the hook of a spring balance into the

hole on the cross-head (see

Fig.

M73) and withdraw

the rack with the balance. The maximum permissible

force required should not exceed

2,72

kg. (6 Ib.).

Cable rack drive-To renew

1.

Remove the wiper blades and arms.

2.

Disconnect the rack from the wiper motor as

described in Wiper motor

-

To remove.

3.

Remove the rack from the tubing by carefully

pulling from the motor end to release the rack from

the wiper arm wheelboxes.

4.

Lubricate the new rack with 'Rocol' M.T.

265

grease, then fit into the tubing. It may be necessary

to rotate the

wheelbox spindles slightly in order to

engage the gears with the rack. Fit the rack to the

motor.

Wheelbox-To renew

1.

Remove the top roll and instrument panel as

described in Chapter

S

-

Body.

2.

Remove the air conditioning equipment located

behind the

facia, for full details refer to Chapter C

-

Heating, De-misting and Ventilating System.

3.

Remove the wiper blade and arm.

4.

Remove the flexible drive.

5.

Unscrew and remove the chrome nut and with-

draw the wheelbox.

Anti-streak mechanism

The anti-streak mechanism fitted to the

'

Lucas'

6.W.

and 16.W. wiper motors enables the wiper arms

and blades to make a complete wiping cycle before

coming to rest in the parked position, thus ensuring

there are no streaks on the screen.

It is imperative, when the mechanism has been

dismantled, that it is correctly assembled (see

Fig.

M76).

1.

The tag on the driving plate and .the recess in

the wave

washer face towards the outside of the

gearwheel.

2.

Rotate the eccentric so that the plastic slide

is depressing the park switch, fit the wave washer

with marks uppermost and just behind tag. Fit the

driving plate bush and driving plate with the latch

just behind the tag.

3.

It is possible to assemble these components

180°from the position previously described. This

must be avoided as the mechanism will 'lock and the

driving plate will fracture before the motor is

parked.

FIG.

M75 ARMATURE

INSULATION TEST

Windscreen washer

jets-TO

clean

1.

Unscrew the knurled portion of each screen jet

to expose the slot.

Loading...

Loading...