Rolls-Royze Silver Shadow

B

Bentlev

T

Series

Workshop

Manual

throttle sealing glands should not be removed as

servicing is not required.

Cars

from

Car

Serial Number

SRH

8742 and

on-

wards. Remove the two rubber seals from the throttle

spindle bore.

19. Unscrew and remove the slow-running valve

complete with spring, seal and brass washer.

20.

Remove the two screws and shakeproof washers

retaining the vacuum take-off plate and union. Lift off

the plate and gasket.

21. Remove the piston lifting pin by extracting the

circlip from its groove with the pin pressed upwards.

22.

Withdraw the pin downwards.

Carburetters-To assemble

Chapter

K

(1 1,11 mm.) diameter bar between the forked lever

and the lip of the float chamber lid. The prongs of

the lever should just rest on the bar

(see

Fig.

K14). If

they do not, carefully bend the lever at the start of

the pronged section until the correct setting is obtained.

13. Examine the piston rod and the outside surface

of the piston for damage.

14.

The piston assembly must be scrupulously clean.

Use paraffin or methylated spirits as a cleaning agent;

do not use abrasive. Clean inside the suction chamber

and piston rod guide using paraffin or methylated

spirits.

15. Fit the damper assembly and washer. Seal the

transfer holes in the piston assembly with rubber plugs

and fit the assembly to the suction chamber.

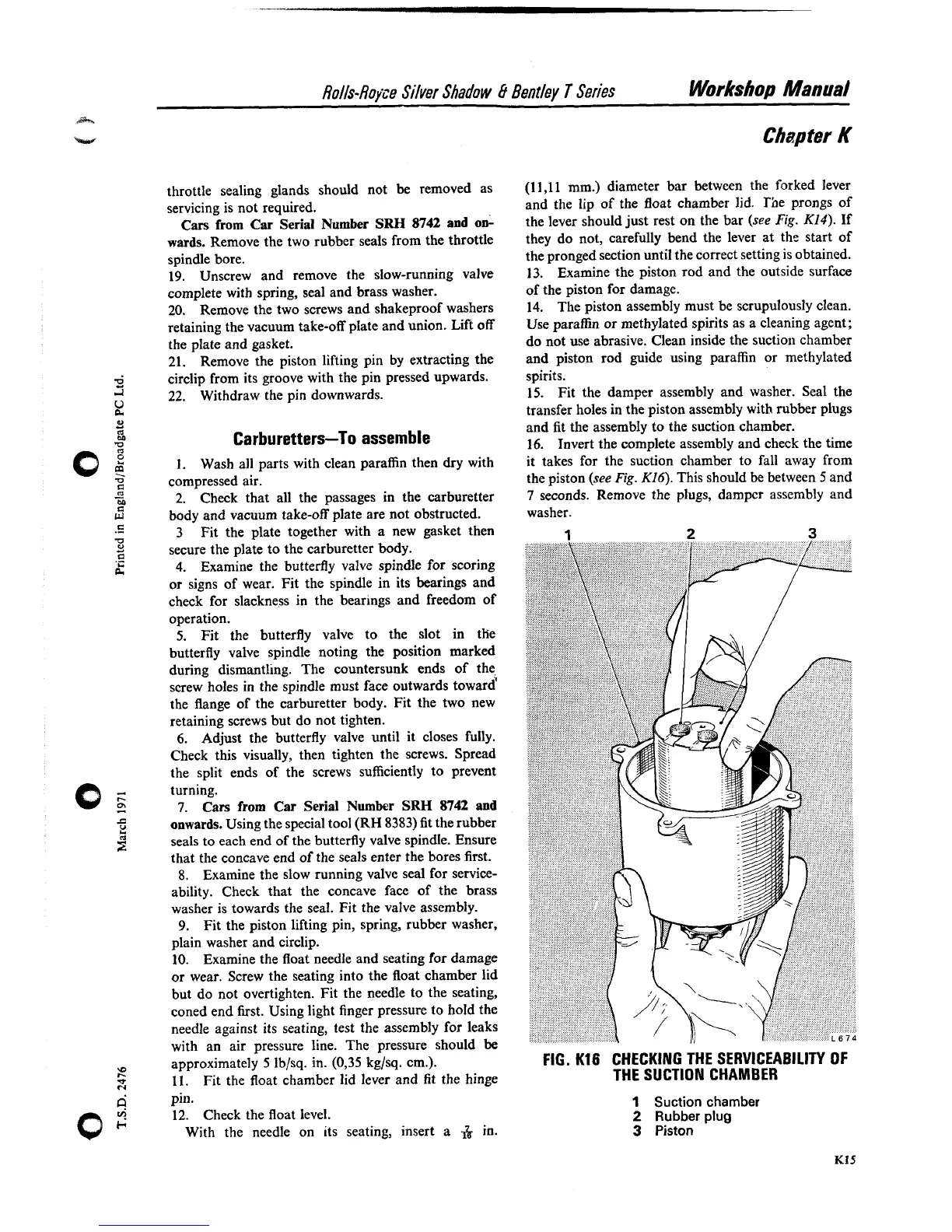

16.

Invert the complete assembly and check the time

I.

Wash all parts with clean paraffin then dry with

it takes for the suction chamber to fall away from

compressed air.

the piston

(see

Fig.

K16). This should be between

5

and

2.

Check that all the passages in the

carburetter

7

seconds. Remove the plugs, dampcr assembly and

body and vacuum take-off plate are not obstructed.

washer.

3 Fit the plate together with

a

new gasket then

1

2

3

secure the plate to the carburetter body.

4.

Examine the butterfly valve spindle for scoring

or signs of wear. Fit the spindle in its bearings and

check for slackness in the

bearlngs and freedom of

operation.

5. Fit the butterfly valve to the slot in the

butterfly valve spindle noting the position marked

during dismantling. The countersunk ends of the,

screw holes in the spindle must face outwards

toward

the flange of the carburetter body. Fit the two new

retaining screws but do not tighten.

6.

Adjust the butterfly valve until it closes fully.

Check this visually, then tighten the screws. Spread

the split ends of the screws sufficiently to prevent

turning.

7.

Cars from Car Serial Number

SRH

8742

and

onwards. Using the special tool

(RH

8383) fit the rubber

seals

to

each end of the butterfly valve spindle. Ensure

that the concave end of the seals enter the bores first.

8. Examine the slow running valve seal for service-

ability. Check that the concave face of the brass

washer is towards the seal. Fit the valve assembly.

9.

Fit the piston lifting pin, spring, rubber washer,

plain washer and circlip.

10.

Examine the float needle and seating for damage

or wear. Screw the seating into the float chamber lid

but do not overtighten. Fit the needle to the seating,

coned end first. Using light finger pressure to hold the

needle against

its

seating, test the assembly for leaks

with an air pressure line. The pressure should be

approximately

5

Ib/sq. in. (0,35 kg/sq. cm.).

FIG.

K16

CHECKING THE SERVICEABILITY

OF

11.

Fit the float chamber lid lever and fit the hinge

THE SUCTION CHAMBER

pin.

12. Check the float level.

With the needle on its seating, insert a

&

in.

1

Suction chamber

2

Rubber plug

3

Piston

Loading...

Loading...