Rolls-Royce Silver Shadow

8

Bentley

T

Series

Workshop

Manual

7.

Remove the three through bolts and spring

washers and withdraw the DE shield complete with

rotor. If 'Loctite' grade A has been used to secure

the through bolts, local heat should be applied with

a heated soldering iron to loosen them, the part

should not be overheated. If necessary use a hide

faced hammer and gently tap the DE shield away

from the stator and SRE shield. Do not damage the

slip ring when laying the DE shield and rotor

assembly on the bench.

Note

The stator is sandwiched between the

two end-shields therefore great care must

be taken at this stage to prevent the full

weight of the stator from falling onto the

three stator phase leads.

8.

Lay the stator and SRE shield assembly

carefully on the bench with the endshield uppermost.

9.

Unsolder the three stator phase leads from the

heatsink terminal tags (do not remove tags from

heatsinks) and separate the SRE shield from the

stator using a hide faced mallet if necessary.

10.

Remove and discard the

'0'

ring from the

shield bearing housing using a sharp pointed probe.

Do not damage the

'0'

ring groove.

11.

Place the DE shield with drive shaft upwards

over a suitable large diameter cylinder so that the

Chapter

M

rotor is encased within the cylinder arid the cylinder

sits squarely against the three end shield webs.

Support the rotor from underneath and gently press

the rotor from the DE shield with a standard

fly-

press.

Note It is unnecessary to strip the diode

assembly from the SRE shield unless it

is established that there is a fault in

one or more of the diodes. Accordingly,

the diodes should next be subjected to

the tests detailed under Alternator

-

Bench testing. If a faulty diode is

detected proceed as instructed in

Alternator

-

Inspection and repair.

Alternator-Inspection and repair

General

After dismantling, all components which require

cleaning should be thoroughly cleaned.

1.

Examine all parts for cracking, corrosion,

serviceability of threads, score marks and excessive

wear. The 'nyloc' pulley nut may be used again

provided that the nylon insert is in reasonable

condition.

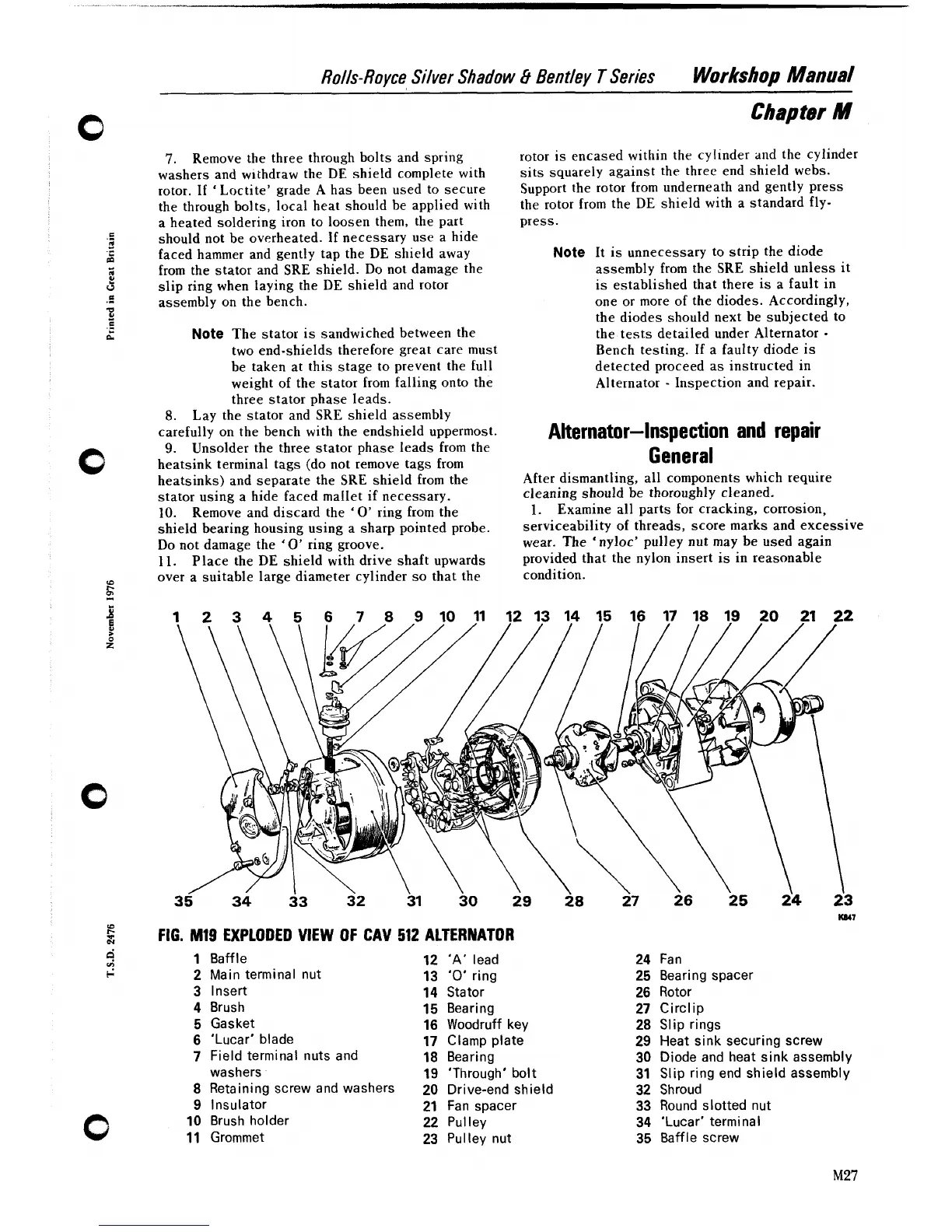

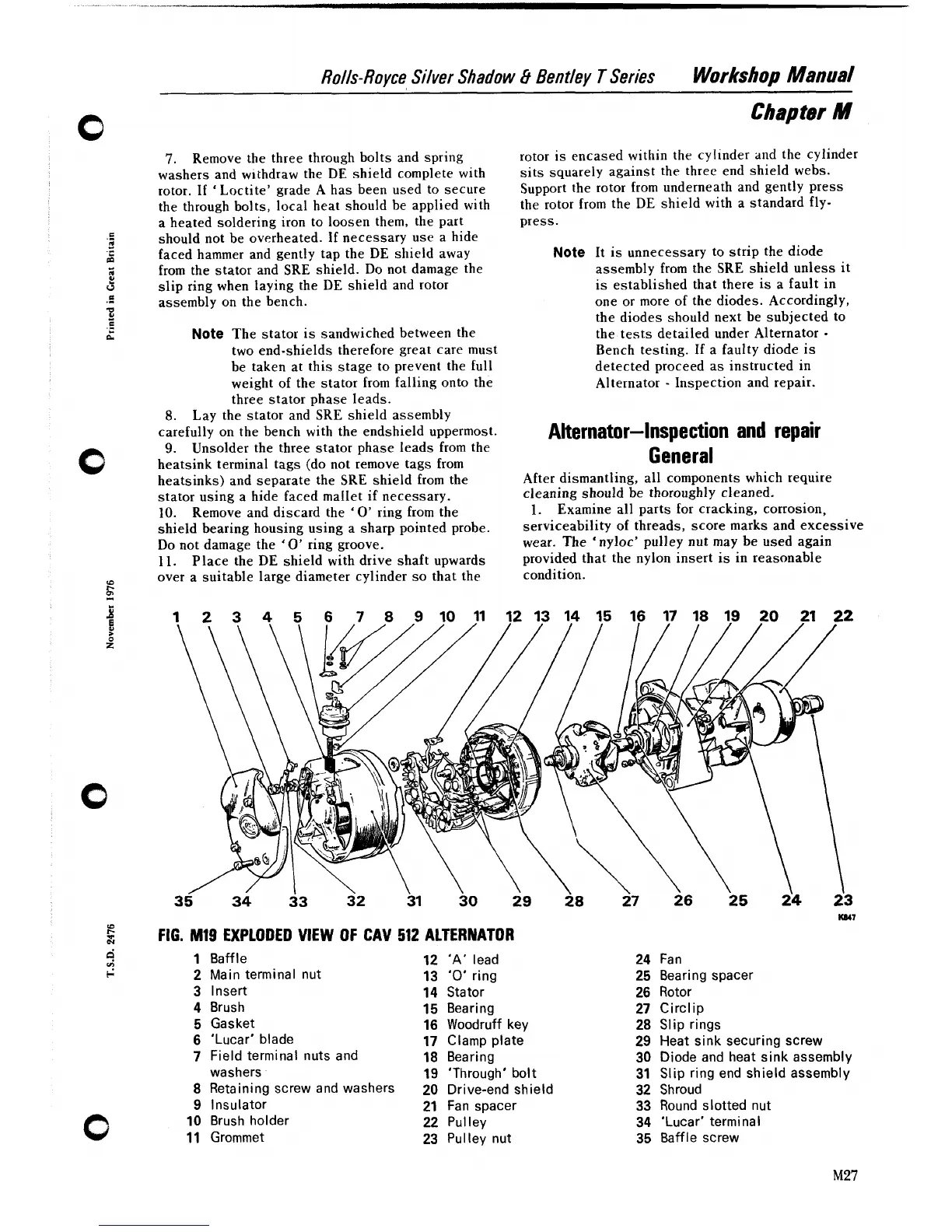

FIG.

MI9

EXPLODED VIEW OF CAV

512

ALTERNATOR

1

Baffle

12

'A'

lead

2

Main terminal nut

13

'0'

ring

3

Insert

14

Stator

4

Brush

15

Bearing

5

Gasket

16

Woodruff key

6

'Lucar' blade

17

Clamp plate

7

Field terminal nuts and

18

Bearing

washers

19

'Through' bolt

8

Retainingscrewandwashers

20

Drive-endshield

9

Insulator

21

Fan spacer

10

Brush holder

22

Pulley

11

Grommet

23

Pulley nut

24

Fan

25

Bearing spacer

26

Rotor

27

Circlip

28

Slip rings

29

Heat sink securing screw

30

Diode and heat sink assembly

31

Slip ring end shield assembly

32

Shroud

33

Round slotted nut

34

'Lucar' terminal

35

Baffle screw

Loading...

Loading...