Workshop

Manual

Rolls-Royce Silver Shadow

8

Bentley

T

Series

Chapter

M

a. Switch the ignition on and observe that the

warning lamp

n~arked CEN illuminates.

b. Switch on all the electrical loads with the

exception of the windscreen wipers.

c. Start the engine, allow it to run at approx-

imately 1000 r.p.m. and observe that the

warning lamp is extinguished.

d. Momentarily increase the engine speed to

approximately 3000

r.p.m. and observe that

the alternator current is approximately 53

amps.

e. With the engine running at approximately

1500

r.p.m. switch off all the loads. The

voltage should rise to between 14.0 and

14.5

volts and then remain constant, the

current reading should drop appreciably.

4.

Should there be a fault in the system this will

be apparent by one or more of the following

symptoms:

a. If the warning lamp does not illuminate

check the bulb and renew if defective.

b. If the bulb is serviceable but does not

illuminate, check the regulator by first

switching off the engine and disconnecting

the lead from terminal

F

on the regulator.

Clip this lead to earth and switch on the

engine. If the lamp now illuminates the

regulator is faulty and must be replaced by

a new regulator.

If

the lamp still remains

unlit then the alternator is faulty and

requires workshop attention (see

Alternator

-

To dismantle).

The tests described in 5 may be used to

locate the alternator fault. Having located

the fault, switch off the engine and

reconnect the

F

lead to

F

terminal.

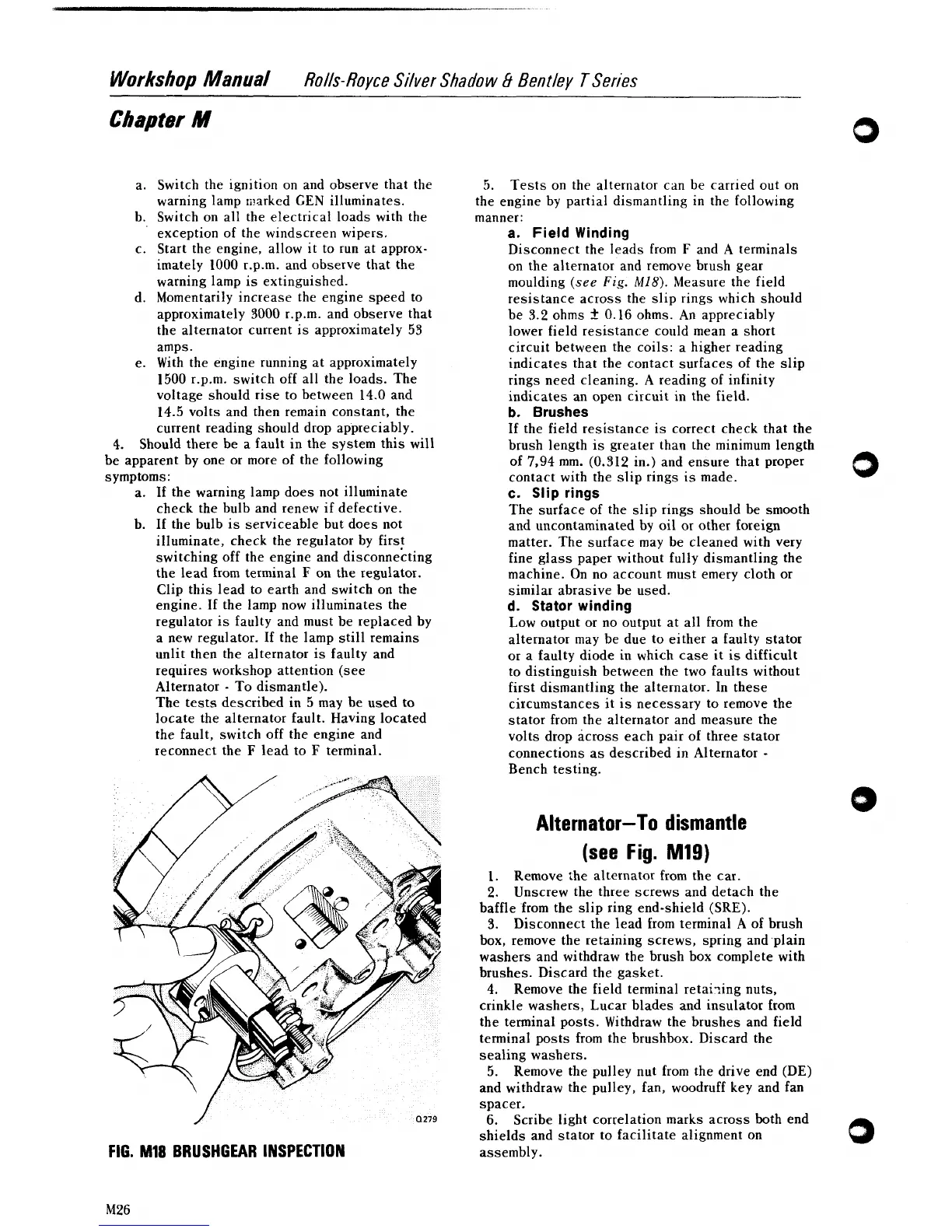

FIG.

MI8

BRUSHGEAR INSPECTION

5.

Tests on the alternator can be carried out on

the engine by partial dismantling in the following

manner:

a.

Field Winding

Disconnect the leads from

F

and

A

terminals

on the alternator and remove brush gear

moulding

(see

Fig.

M18).

Measure the field

resistance across the slip rings which should

be

3.2

ohms

2

0.16 ohms. An appreciably

lower field resistance could mean a short

circuit between the coils: a higher reading

indicates that the contact surfaces of the slip

rings need cleaning. A reading of infinity

indicates an open circuit in the field.

b.

Brushes

If the field resistance is correct check that the

brush length is greater than the minimum length

of

7,94

mm. (0.312 in.) and ensure that proper

contact with the slip rings is made.

c.

Slip rings

The surface of the slip rings should be smooth

and uncontaminated by oil or other foreign

matter. The surface may be cleaned with very

fine glass paper without fully dismantling the

machine. On no account must

emery cloth or

similar abrasive be used.

d.

Stator winding

Low output or no output at all from the

alternator may be due to either a faulty stator

or a

faulty diode in which case it is difficult

to distinguish between the two faults without

first dismantling the alternator. In these

circumstances it is necessary to remove the

stator from the alternator and measure the

volts drop across each pair of three stator

connections as described in Alternator

-

Bench testing.

Alternator-To dismantle

(see

Fig.

M19)

1.

Remove ihe alternator from the car.

2.

Unscrew the three screws and detach the

baffle from the slip ring end-shield (SRE).

3..

Disconnect the lead from terminal

A

of brush

box, remove the retaining screws, spring and plain

washers and withdraw the brush box complete with

brushes. Discard the gasket.

4.

Remove the field terminal retaiying nuts,

crinkle washers, Lucar blades and insulator from

the terminal posts. Withdraw the brushes and field

terminal posts from the brushbox. Discard the

sealing washers.

5.

Remove the pulley nut from the drive end (DE)

and withdraw the pulley, fan, woodruff key and fan

spacer.

6.

Scribe light correlation marks across both end

shields and stator to facilitate alignment on

assembly.

0

Loading...

Loading...