Worksho~

Manual

Rolls

Royce

Silver

Shadow

8

Bentley

T

Series

Chapter

K

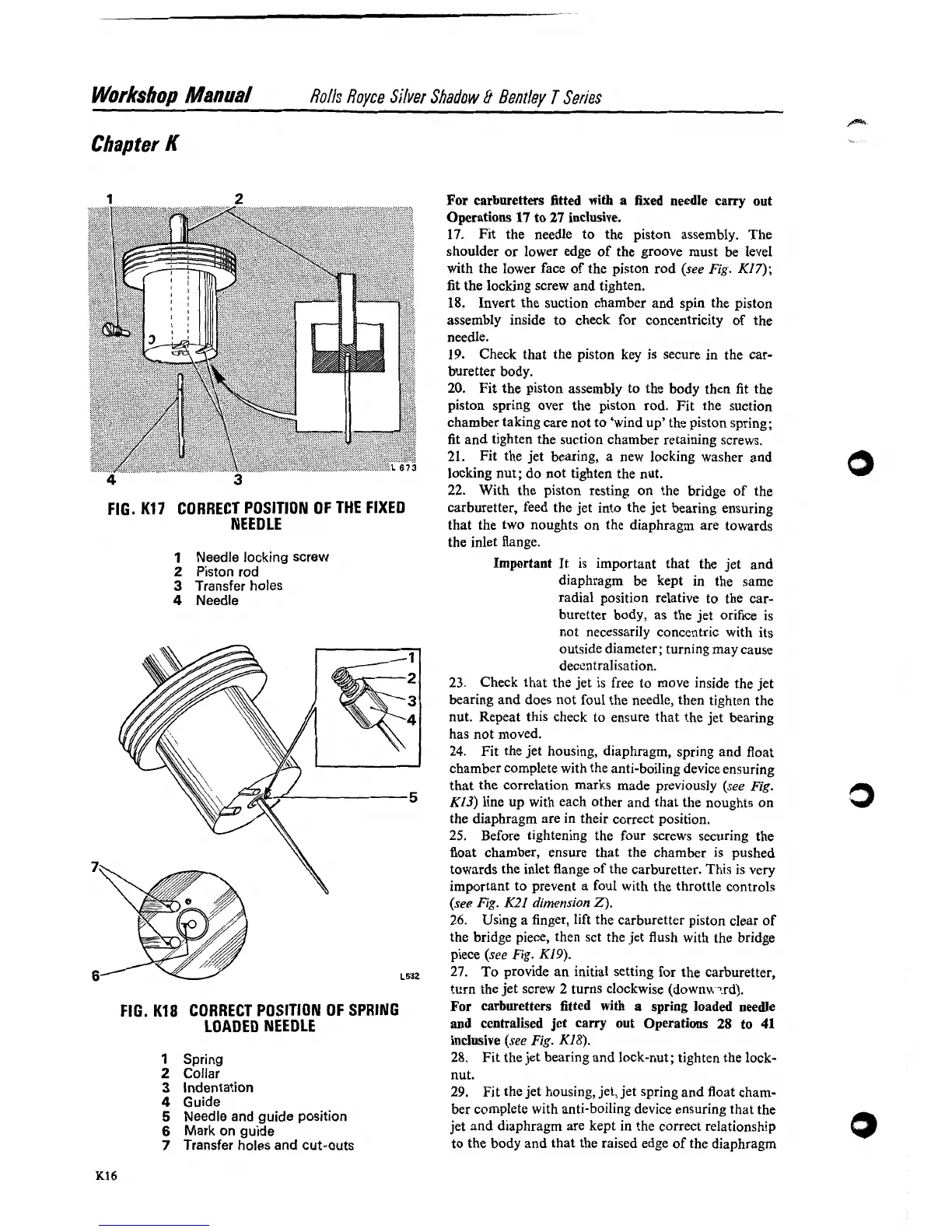

FIG.

K17

CORRECT POSITION OF THE FIXED

NEEDLE

1

Needle locking screw

2

Piston rod

3

Transfer holes

4

Needle

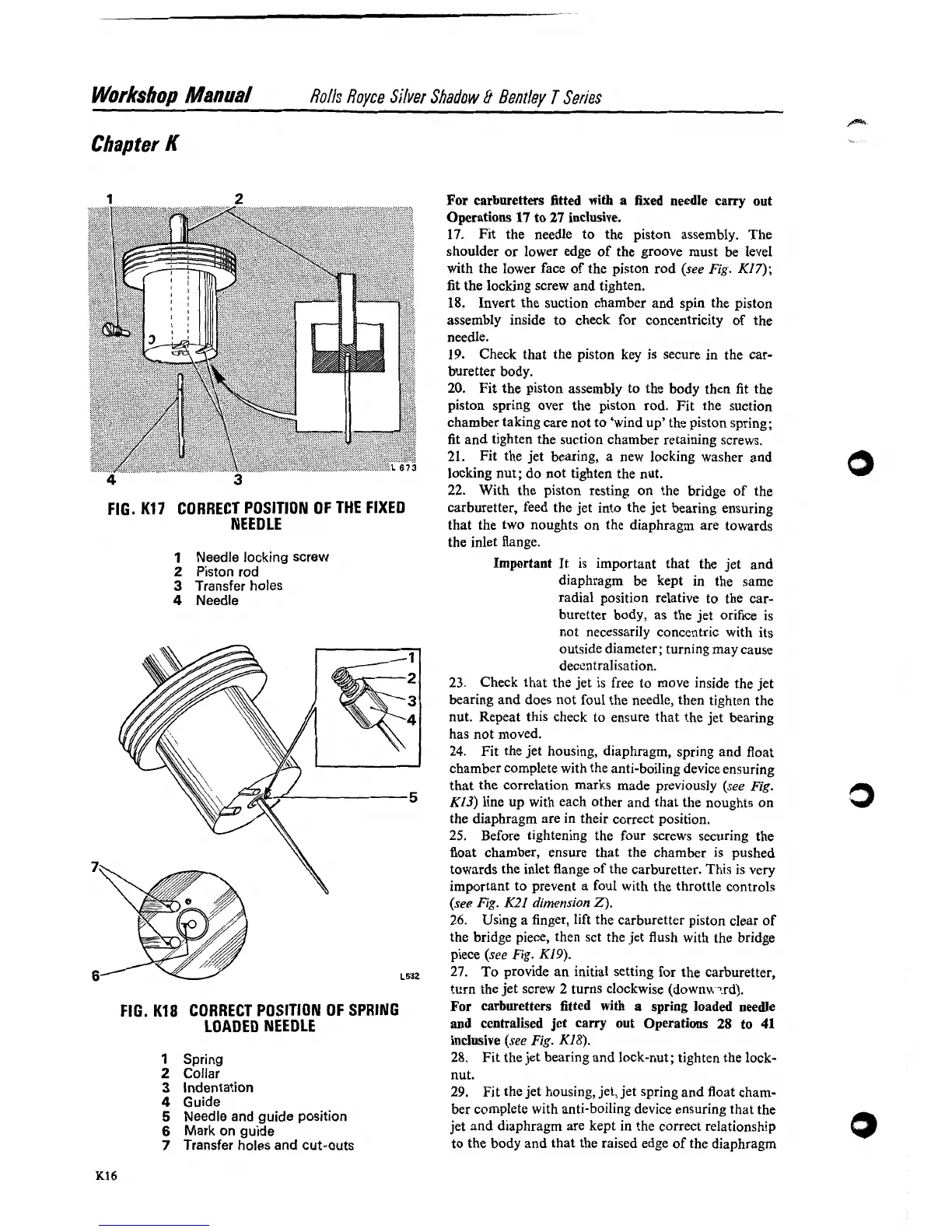

FIG.

K18

CORRECT POSITION OF SPRING

LOADED NEEDLE

1

Spring

2

Collar

3

Indentation

4

Guide

5

Needle and guide position

6

Mark

on guide

7

Transfer holes and cut-outs

For carburetters fitted with a fixed needle carry out

Operations

17

to

27

inclusive.

17.

Fit the needle to the piston assembly. The

shoulder or lower edge of the groove must be level

with the lower face of the piston rod

(see Fig.

K17);

fit the locking screw and tighten.

18.

Invert the suction chamber and spin the piston

assembly inside to check for concentricity of the

needle.

19. Check that the piston key is secure in the car-

buretter body.

20. Fit the piston assembly to the body then fit the

piston spring over the piston rod. Fit the suction

chamber taking care not to 'wind up' the piston spring;

fit and tighten the suction chamber retaining screws.

21. Fit the jet bearing, a new locking washer and

locking nut; do not tighten the nut.

22. With the piston resting on the bridge of the

carburetter, feed the jet into the jet bearing ensuring

that the two noughts on the diaphragm are towards

the inlet flange.

Important

It is important that the jet and

diaphragm be kept in the same

radial position relative to the car-

buretter body, as the jet orifice is

not necessarily concentric with its

outside diameter; turning may cause

decentralisation.

23. Check that the jet is free to move inside the jet

bearing and does not foul the needle, then tighten the

nut. Repeat this check to ensure that the jet bearing

has not moved.

24. Fit the jet housing, diaphragm, spring and float

chamber complete with the anti-boiling device ensuring

that the correlation marks made previously

(see Fig.

K13) line up with each other and that the noughts on

the diaphragm are in their correct position.

25.

Before tightening the four screws securing the

float chamber, ensure that the chamber is pushed

towards the inlet flange of the carburetter. This is very

important to prevent a foul with the throttle controls

(see Fig.

K21

dimension

2).

26.

Using a finger, lift the carburetter piston clear of

the bridge piece, then

sct the jet flush with the bridge

piece

(see

Fig.

K19).

27.

To provide an initial setting for the carburetter,

turn the jet screw

2

turns clockwise (downw7.rd).

For carburetters fitted with

a

spring loaded needle

and centralised jet carry out Operations

28

to

41

inclusive

(see

Fig.

K18).

28.

Fit the jet bearing and lock-nut; tighten the lock-

nut.

29. Fit the jet housing, jet, jet spring and float cham-

ber

con~plete with anti-boiling device ensuring that the

jet and diaphragm are kept in the correct relationship

to the body and that the raised edge of the diaphragm

Loading...

Loading...