Workshop

Manual

Rolls Royce Silver Shadow

6

Bentley

T

Ser~es

Chapter

N

2. Lubricate the new valve spool damping

'0'

ring

5.

Slide the spool spring over the stub shaft and,

seal with the approved power steering fluid and insert

using a small screwdriver, ease the spool spring down

the seal into the valve spool groove.

until it is seated in the stub shaft groove.

3. Insert the stub shaft into the valve body, aligning

6.

Lubricate the new cap-to-worm

'0'

ring seal with

the groove in the valve cap with the pin in the valve the approved power steering fluid and insert it into

body

(see

Fig.

N34).

Tap lightly on the cap with a hide

the valve body.

mallet until the cap is against the shoulder in the

Note

Do not

fit

the upper thrust bearing

valve body, with the valve body pin in the cap groove. assembly to the valve assembly at

tais

Hold these parts together during the remainder of the stage.

assembly procedure.

4.

Lubricate the valve spool with the approved

Rocking shah gear and rocking shaft cover-

power steering fluid and slide the spool over the stub

TO inspect

shaft with the notch towards the valve body. Align

the notch with the spool drive pin in the cap groove

1.

Inspect the rocking shaft bearing surface in the

stub and carefully engage the spool in the valve body

rocking shaft cover for excessive wear or scoring. If

bore.

badly worn or scored, renew the rocking shaft cover.

Note

Because the clearance between the spool

2.

Examine the rocking shaft sector teeth and

and valve body is very fine, extreme care

bearing and the seal surface.

If

excessiv'ely worn,

must be taken when assembling these

pitted or scored, renew the rocking shaft.

-

parts. Push the spool evenly and slowly,

with a slight twisting motion, until it

3. Check the rocking shaft for excessive wear or for

reaches the drive pin. Rotate the spool

a broken spring as follows.

slowly with pressure until the notch

en-

4.

Clamp the rocking shaft in a vice.

gages the pin. Before pushing the spool

completely in, make sure that the damp-

ing

'0'

ring seal is evenly distributed in

the spool groove. Slowly push the spool

completely in, taking care not to cut or

pinch the

'0'

ring seal by inserting the

spool beyond its normal position.

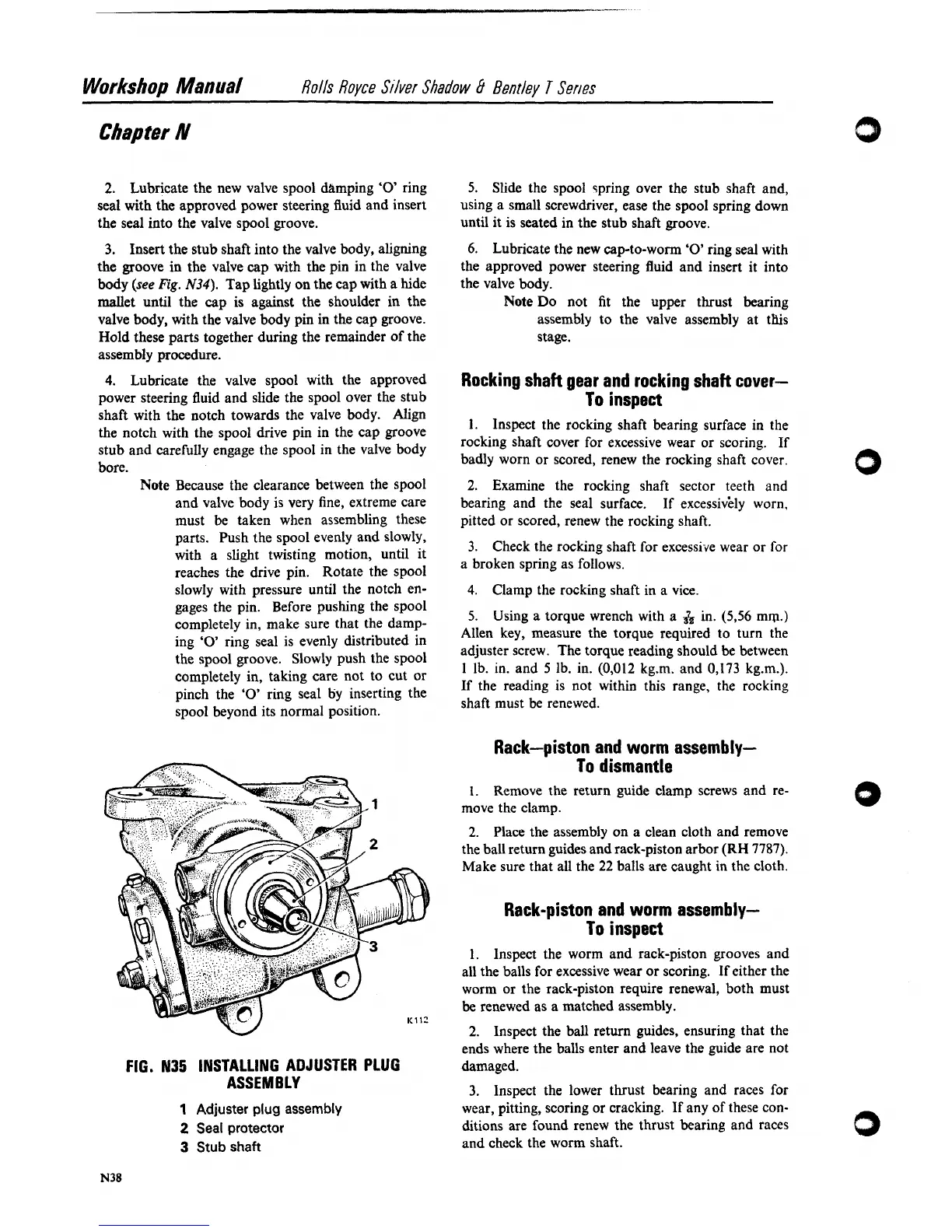

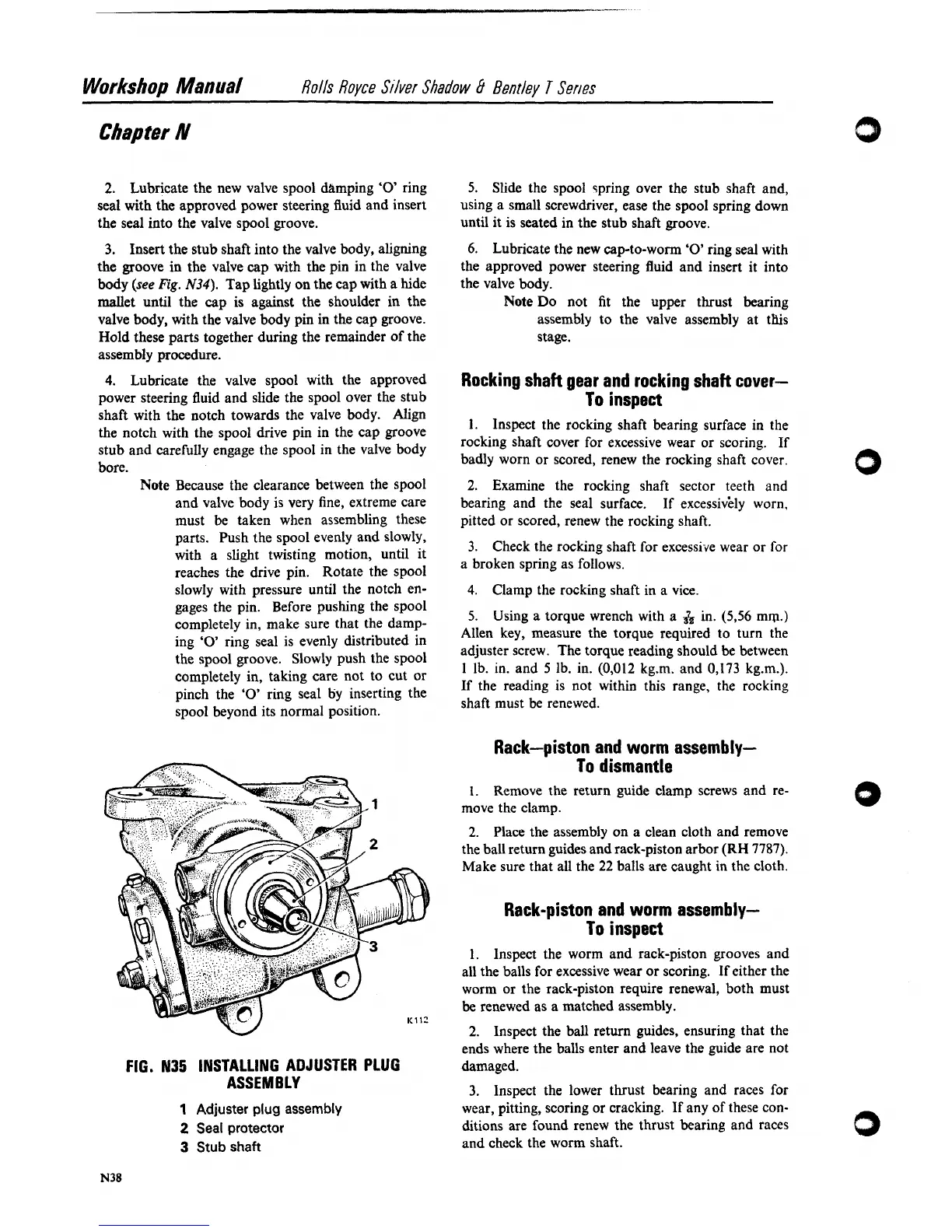

FIG.

N35

INSTALLING ADJUSTER PLUG

ASSEMBLY

1

Adjuster plug assembly

2

Seal protector

3

Stub

shaft

5.

Using a torque wrench with a

&

in.

(5,56

mm.)

Allen key, measure the torque required to turn the

adjuster screw. The torque reading should be between

1

lb. in. and

5

lb. in. (0,012 kg.m. and 0,173 kg.m.).

If the reading is not within this range, the rocking

shaft must be renewed.

Rack-piston and worm assembly-

To dismantle

1.

Remove the return guide clamp screws and re-

move the clamp.

2.

Place the assembly on a clean cloth and remove

the ball return guides and rack-piston arbor (RH 7787).

Make sure that all the

22

balls are caught in the cloth.

Rack-piston and worm assembly-

To inspect

1.

Inspect the worm and rack-piston grooves and

all the balls for excessive wear or scoring. If either the

worm or the rack-piston require renewal, both must

be renewed as a matched assembly.

2.

Inspect the ball return guides, ensuring that the

ends where the balls enter and leave the guide are not

damaged.

3.

Inspect the lower thrust bearing and races for

wear, pitting, scoring or cracking. If any of these con-

ditions are found renew the thrust bearing and races

and check the worm shaft.

Loading...

Loading...