Rolls-Royce

Silver

Shadow

8

Bentley

T

Series

Workshop

Manual

Chapter

N

3.

Examine and renew

if

necessary, the two rubber

bushes of the lower support bracket and ensure that

the distance tube is fitted.

4.

Examine the large circlip and groove into which

it seats at the base of the column. The circlip and

groove must be clean and free of paint, the circlip

should be checked in the groove to see that it will seat

correctly.

5.

Fit the column through the rubber grommet in

the toe-board. Take extra care not to knock either

end of the

inner column, thus causing possible damage

c

to the injected plastic rivets, rendering the column

cl

userviceable.

~i

6:

Take the weight of the column by fitting the two

cd

screws of the upper mounting bracket with a washer

-

M

5

fitted to each side of the capsule. Pass the screws

E

.-

through the respective capsules and distance tubes

3

and locate and finger tighten the tapped plate.

i

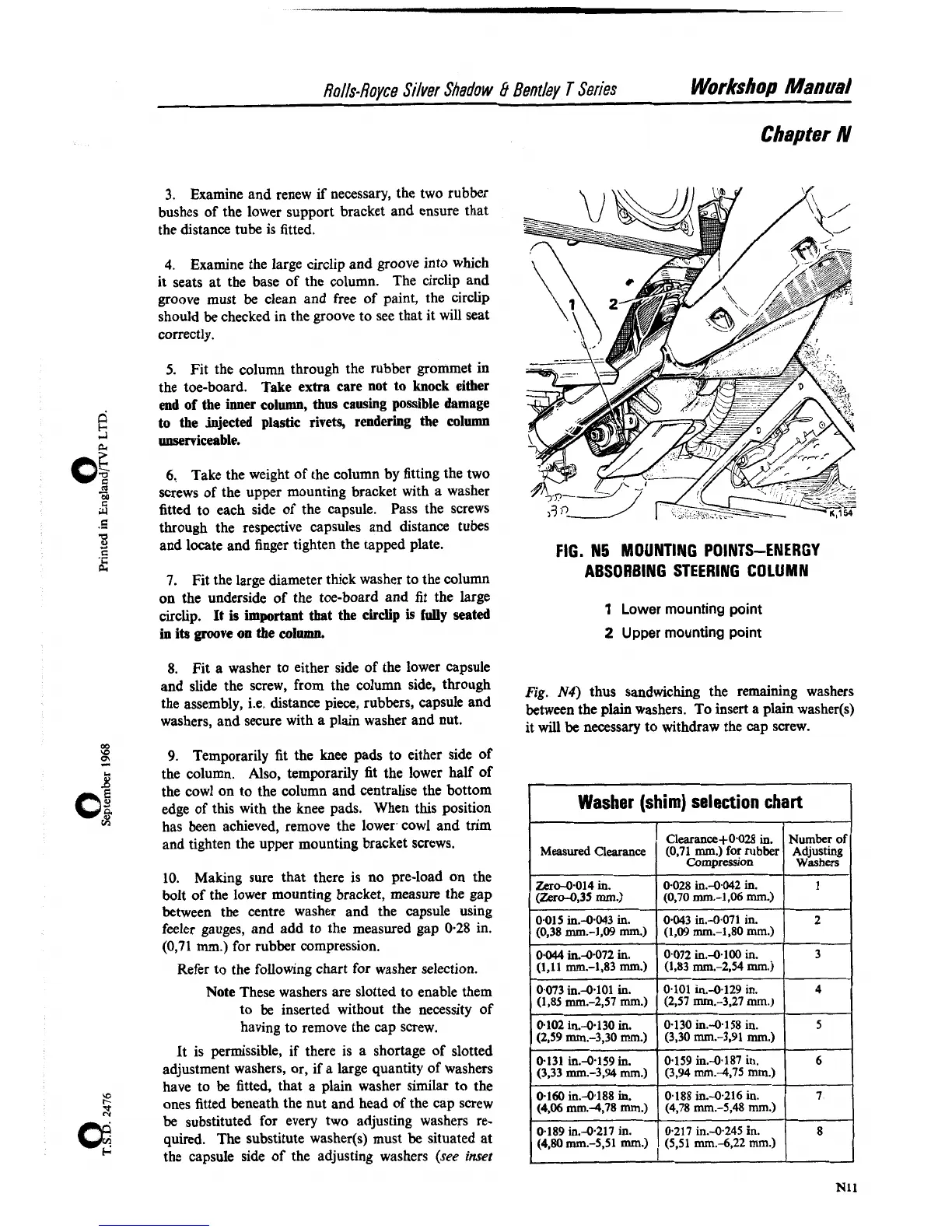

FIG. N5 MOUNTING POINTS-ENERGY

7.

Fit the large diameter thick washer to the column

ABSORBING STEERING COLUMN

on the underside of the toe-board and fit the large

circlip. It is important that the circlip is

fully

seated

1

Lower mounting point

in

its

groove

on

the

column.

2

Upper mounting point

8. Fit a washer to either side of the lower capsule

and slide the screw, from the column side, through

Fig.

N4)

thus

sandwiching

the remaining

the assembly, i.e. distance piece, rubbers, capsule and

between the plain washers.

T~

insert a plain washer(s)

washers, and secure with a plain washer and nut.

it will

be

necessary to withdraw the cap screw.

m

\O

2

9.

Temporarily fit the knee pads to either side of

8

the column. Also, temporarily fit the lower half of

the cowl on to the column and centralise the bottom

o[

edge of this with the knee pads. When this position

IA

has been achieved, remove the lower cowl and trim

and tighten the upper mounting bracket screws.

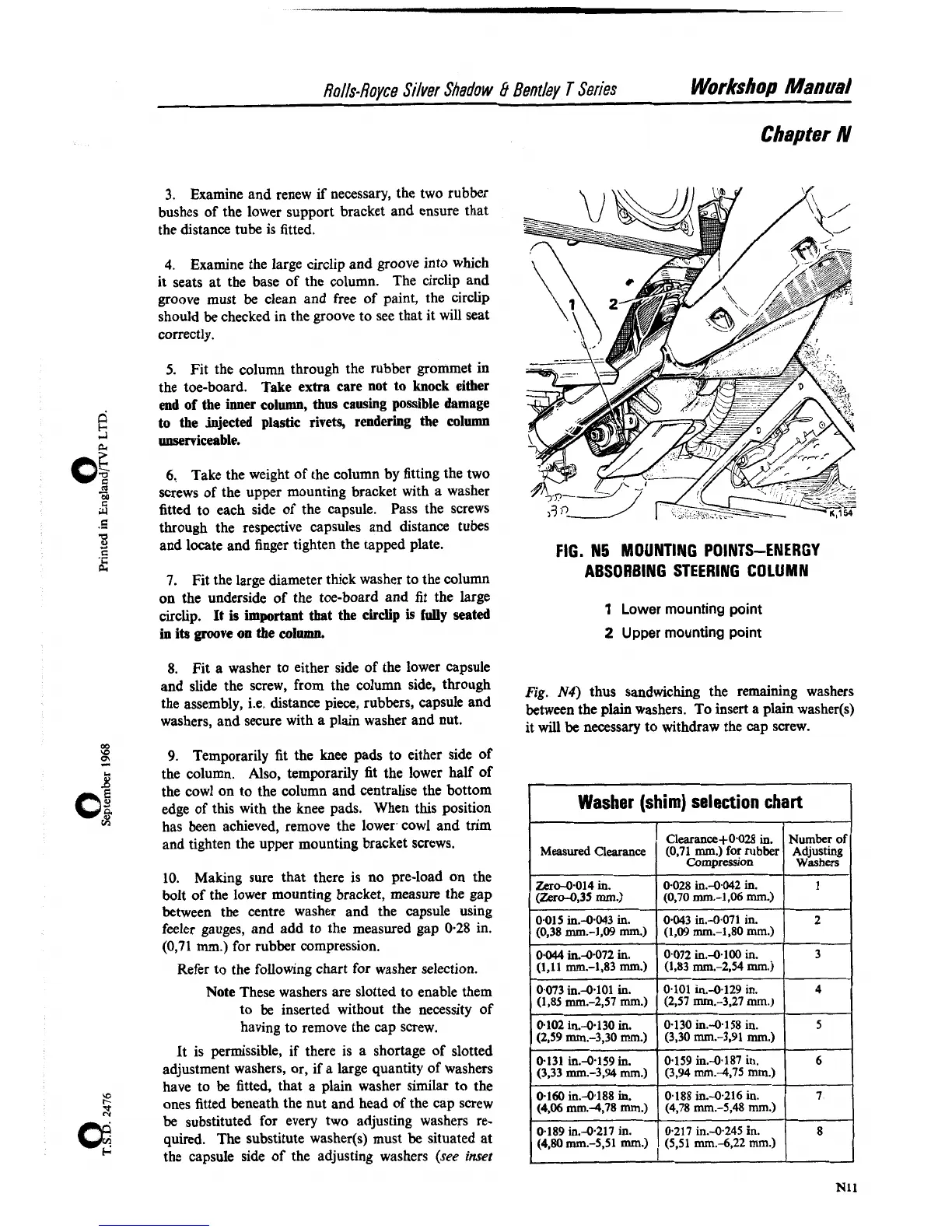

10.

Making sure that there is no pre-load on the

bolt of the lower mounting bracket, measure the gap

between the centre washer and the capsule using

feeler gauges, and add to the measured gap

0-28 in.

(0,71

mm.)

for rubber compression.

Refer to the following chart for washer selection.

I

Note These washers are slotted to enable them

I

to be inserted without the necessity of

having to remove the cap screw.

It is permissible, if there is a shortage of slotted

adjustment washers, or, if a large quantity of washers

have to be fitted, that a plain washer similar to the

ones fitted beneath the nut and head of the cap screw

be substituted for every two adjusting washers re-

quired. The substitute

washer(s) must be situated at

the capsule side of the adjusting washers

(see

inset

Washer (shim) selection chart

Number

of

Adjusting

Washers

1

2

3

4

5

6

7

8

Measured

Clearance

Zero4014 in.

I

(Zer0-0~35

mm.)

0.015 in.4.043 in.

(0,38 mm.-1,09

mm)

0.044

in.4072 in.

(1,ll mm.-1,83 mm.)

0.073 in.4.101 in.

(1,85 mm.-2,57 mm.)

0.102 in.4.130 in.

(2.59

mm.-3,30

mm.)

0.131 in.4159 in.

(3,33 mm.-3,94 mm.)

0-160 in.4188

in.

(4.06 mm.4,78

mm.)

0-189 in.4.217 in.

(4,80

mm.-$51 mm.)

Clearance+0.028

in.

(0.71 Cornpress~on mm.)

for

rubber

0.028 in.--0.042 in.

(0,70 mm.-1,M mm.)

0.043 in.4071 in.

(1,W mm.-1.80

rnrn.)

0.072 in.4.100 in.

(1.83

mt11.-2,54 mm.)

0.101 in.4129 in.

(237 mm.-3,27

mm.)

0.130 in.4158 in.

(3,30 mm.-3.91 mm.)

0.159 in.4.187 in.

(3,94 mm.4.75 mm.)

0.188 in.4.216 in.

(4,78 mm.-5,48

mm.)

0.217 in.4245

in.

(5,51 mm.-6,22 mm.)

Loading...

Loading...