Workshop

Manual

Rolls-Royce Silver Shadow

B

Bentley

T

Series

Chapter

N

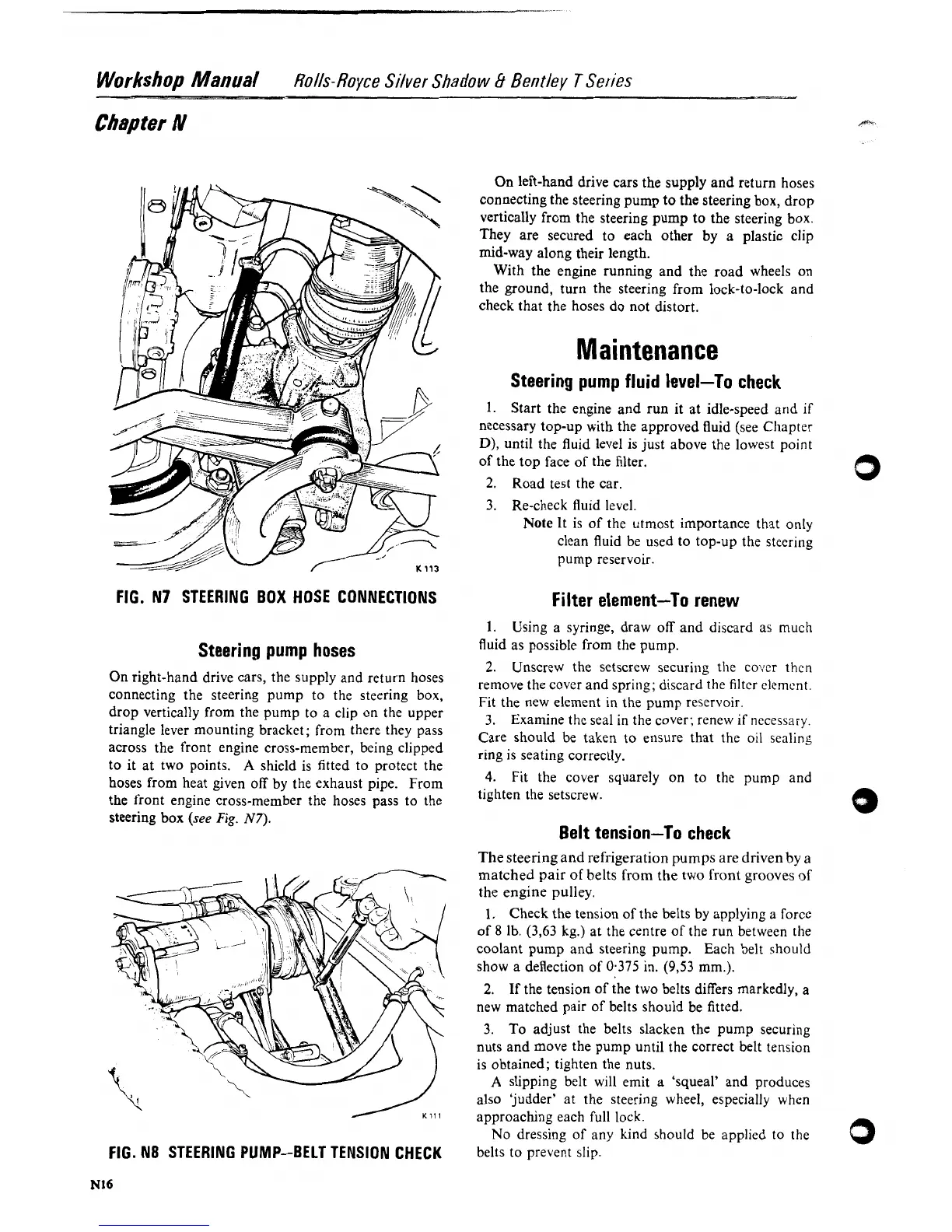

On left-hand drive cars the supply and return hoses

connecting the steering pump to the steering box, drop

vertically from the steering pump to the steering box.

They are secured to each other by

a

plastic clip

mid-way along their length.

With the engine running and the road wheels on

the ground, turn the steering from lock-to-lock and

check that the hoses do not distort.

Maintenance

FIG. N7 STEERING BOX HOSE CONNECTIONS

Steering pump hoses

On right-hand drive cars, the supply and return hoses

connecting the steering pump to the steering box,

drop vertically from the pump to a clip on the upper

triangle lever mounting bracket; from there they pass

across the front engine cross-member, being clipped

to it at two points.

A

shield is fitted to protect the

hoses from heat given off by the exhaust pipe. From

the front engine cross-member the hoses pass to the

steering box

(see

Fig.

N7).

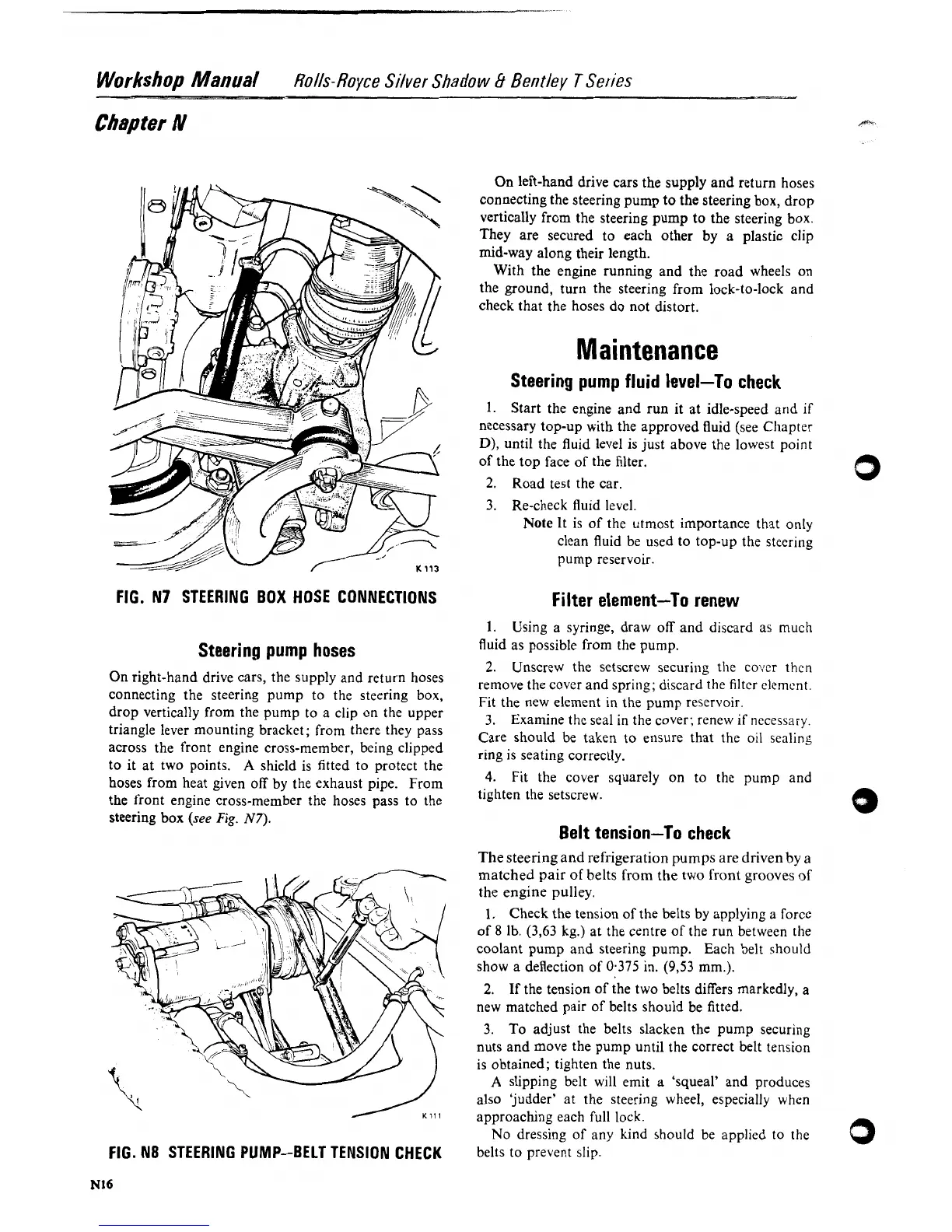

FIG.

N8

STEERING PUMP-BELT TENSION CHECK

Steering pump fluid level-To check

1.

Start the engine and run it at idle-speed and if

necessary top-up with the approved fluid (see Chapter

D),

until the fluid level is just above the lowest point

of the top face of the filter.

2.

Road test the car.

0

3.

Re-check fluld level.

Note

It is of the utmost importance that only

clean fluid be used to top-up the steering

pump reservoir.

Filter element-To renew

1.

Using a syringe, draw off and discard as much

fluid as possible from the pump.

2.

Unscrew the setscrew securing the cover then

remove the cover and spring; discard the filter

elemcnt.

Fit the new element in the pump reservoir.

3.

Examine the seal

in

the cover; renew if necessary.

Care should be taken to ensure that the oil sealing

ring is seating correctly.

4.

Fit the cover squarely on to the pump and

tighten the setscrew.

Q

Belt tension-To check

The steering and refrigeration pumps are driven

by

a

matched pair of belts from the two front grooves of

the engine pulley.

1.

Check the tension of the belts by applying a force

of

8

lb.

(3,63

kg.) at the centre of the run between the

coolant pump and steering pump. Each belt should

show a deflection of

0.375

in.

(933

mm.).

2.

If

the tension of the two belts differs markedly,

a

new matched pair of belts should be fitted.

3.

To adjust the belts slacken the pump securing

nuts and move the pump until the correct belt tension

is obtained; tighten the nuts.

A

slipping belt will emit a 'squeal' and produces

also 'judder' at the steering wheel, especially when

approaching each full lock.

No dressing of any kind should be applied to the

0

belts to prevent slip.

Loading...

Loading...