Rolls-K'jyce Silver Shadow

8

Bentley

T

Series

Workshop

Manual

Exhaust manifolds

-

To remove

1.

Support the

downtake pipes just forward of

the front

silencer(s) with wood blocks and jacks.

2.

Slacken and remove the bolts to the

'A'

and

'B'

bank downtake to manifold, spherical joints.

Remove the clamps.

3.

If fitted remove the two choke stove pipes

from the unions located on

'B'

bank manifold.

Blank off the pipes to prevent ingress of dirt

(see

Fig.

Q2

and

Qll).

4.

Remove the setscrews and distance pieces

securing the manifolds to the cylinder heads, then

detach the manifolds, taking care to retain the

sealing rings from the

downtake joints.

5.

Discard the joints fitted between the mani-

folds and the cylinder heads.

6.

Using a flat scraper remove all traces of

carbon from the machined faces of the exhaust

manifolds and the exhaust port faces on the

cylinder heads. Extra care must be taken when

scraping the cylinder heads not to damage the

faces of the aluminium.

7.

Blank off the ports in the cylinder heads to

prevent the ingress of dirt and other foreign matter.

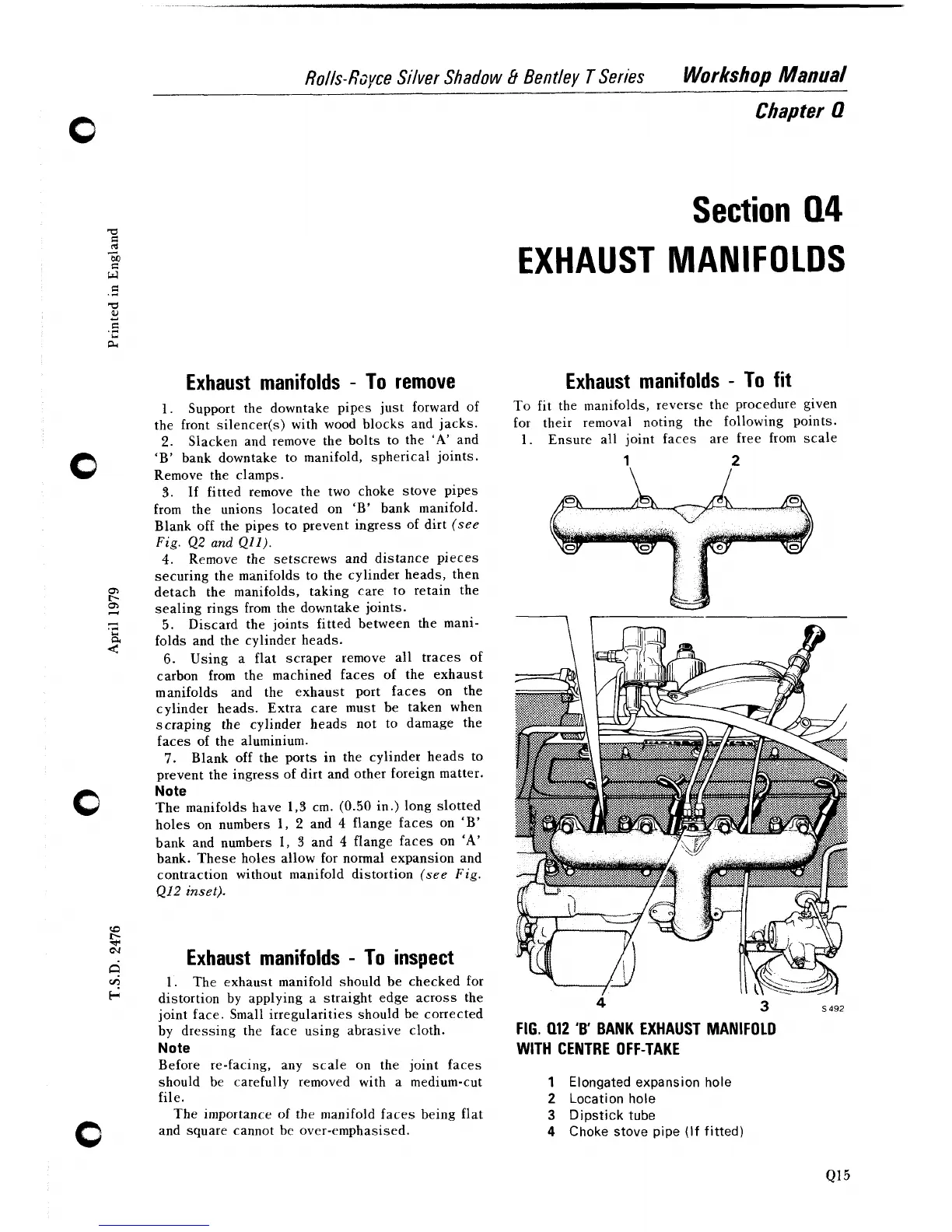

Note

The manifolds have

1,3

cm.

(0.50

in.) long slotted

holes on numbers 1,

2

and

4

flange faces on

'B'

bank and numbers 1,

3

and

4

flange faces on

'A'

bank. These holes allow for normal expansion and

contraction without manifold distortion

(see

Fig.

Q12

inset).

Exhaust manifolds

-

To inspect

1.

The exhaust manifold should be checked for

distortion by applying a straight edge across the

joint face. Small irregularities should be corrected

by dressing the face using abrasive cloth.

Note

Before re-facing, any scale on the joint faces

should be carefully removed with a medium-cut

file.

The importance of the

manifold faces being flat

and square cannot be over-emphasised.

Chapter

Q

Section

Q4

EXHAUST MANIFOLDS

Exhaust manifolds

-

To

fit

To fit the manifolds, reverse the procedure given

for their removal noting the following points.

1. Ensure all joint faces are free from scale

1

2

4

3

S

492

FIG.

Q12

'B'

BANK EXHAUST MANIFOLD

WITH CENTRE OFF-TAKE

1

Elongated expansion hole

2

Location hole

3

Dipstick tube

4

Choke stove pipe (If fitted)

Loading...

Loading...