Workshop

Manual

Rolls- Royce Silver Shadow

8

Bentlev

T

Series

Chapter

M

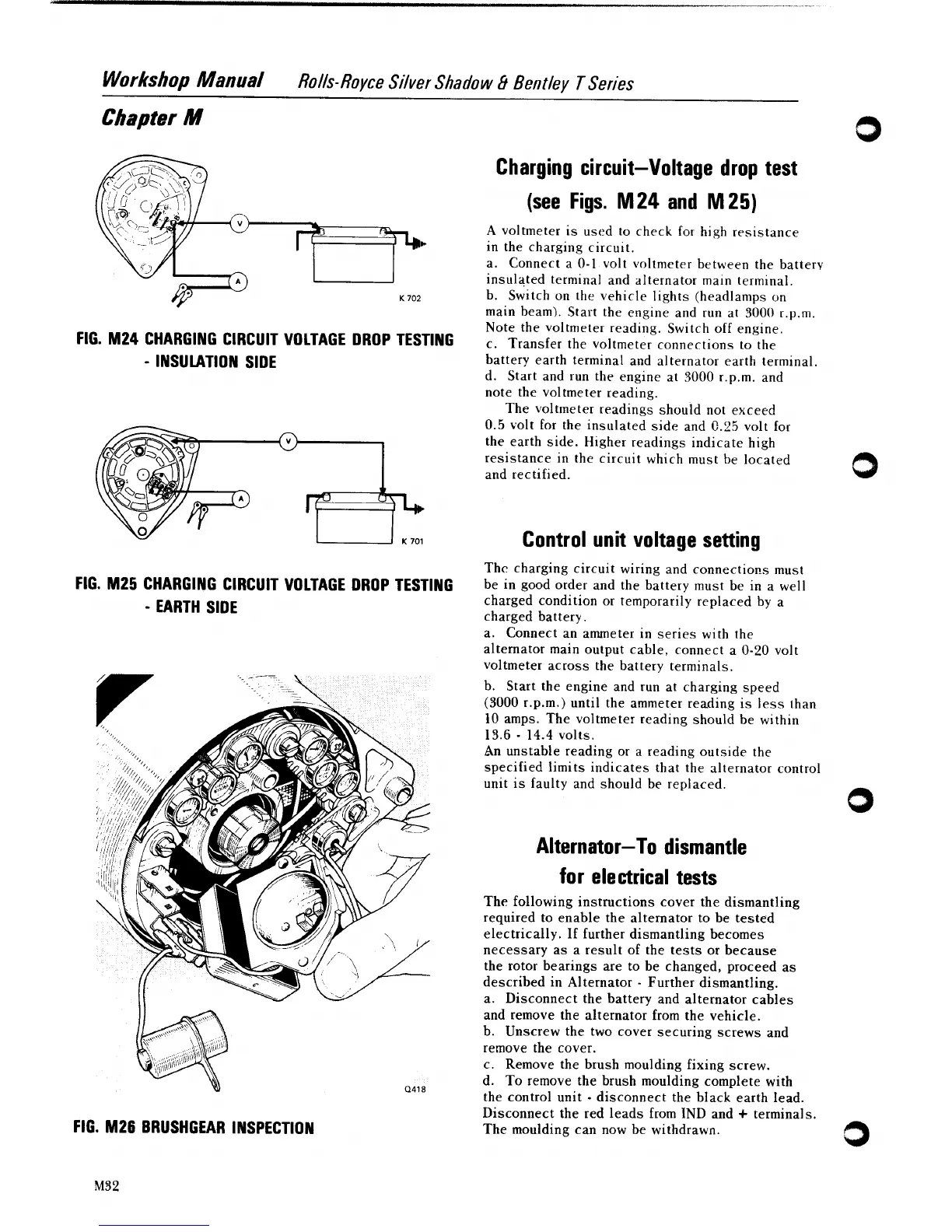

FIG. M24 CHARGING CIRCUIT VOLTAGE DROP TESTING

-

INSULATION SlDE

FIG. M25 CHARGING CIRCUIT VOLTAGE DROP TESTING

-

EARTH SlDE

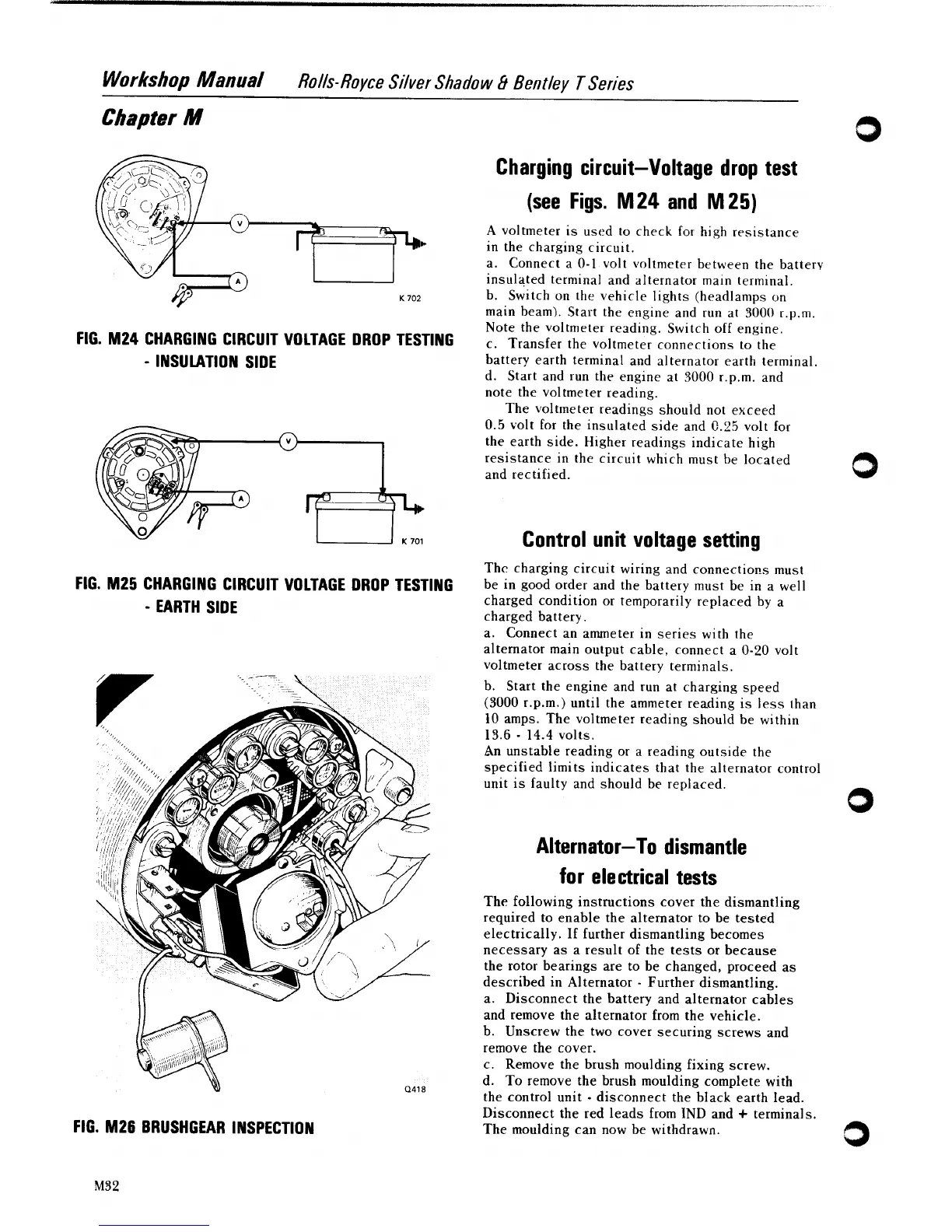

FIG. M26 BRUSHGEAR INSPECTION

Charging circuit-Voltage drop test

(see Figs.

M

24

and

M

25)

A

voltmeter is used to check for high resistance

in the charging circuit.

a. Connect a 0-1 volt voltmeter between the battery

insulated terminal and alternator main terminal.

b. Switch on the vehicle lights

(headlamps on

main beam). Start the engine and run at 3000

r.p.rn.

Note the voltmeter reading. Switch off engine.

c. Transfer the voltmeter connections to the

battery earth terminal and alternator earth terminal.

d. Start and run the engine at 3000

r.p.m. and

note the voltmeter reading.

The voltmeter readings should not exceed

0.5

volt for the insulated side and

C.25

volt for

the earth side. Higher readings indicate high

resistance in the circuit which must be located

and rectified.

Control unit voltage setting

Thc charging circuit wiring and connectio~s must

be in good order and the battery must be in a well

charged condition or temporarily replaced by a

charged battery.

a. Connect an ammeter in series with the

alternator main output cable, connect a 0-20 volt

voltmeter across the battery terminals.

b.

Start the engine and run at charging speed

(3000

1.p.m.) until the ammeter reading is less than

10 amps. The voltmeter reading should be within

13.6

-

14.4

volts.

An unstable reading or a reading outside the

specified limits indicates that the alternator control

unit is faulty and should be replaced.

Alternator-To dismantle

for electrical tests

The following instructions cover the dismantling

required to enable the alternator to be tested

electrically. If further dismantling becomes

necessary as a result of the tests or because

the rotor bearings are to be changed, proceed as

described in Alternator

-

Further dismantling.

a. Disconnect the battery and alternator cables

and remove the alternator from the vehicle.

b. Unscrew the two cover securing screws and

remove the cover.

c. Remove the brush moulding fixing screw.

d. To remove the brush moulding complete with

the control unit

-

disconnect the black earth lead.

Disconnect the red leads from IND and

+

terminals.

The moulding can now be withdrawn.

Loading...

Loading...