Workshop

Manual

Rolls Royce Silver Shadow

19

Bentley

T

Serles

Chapter

K

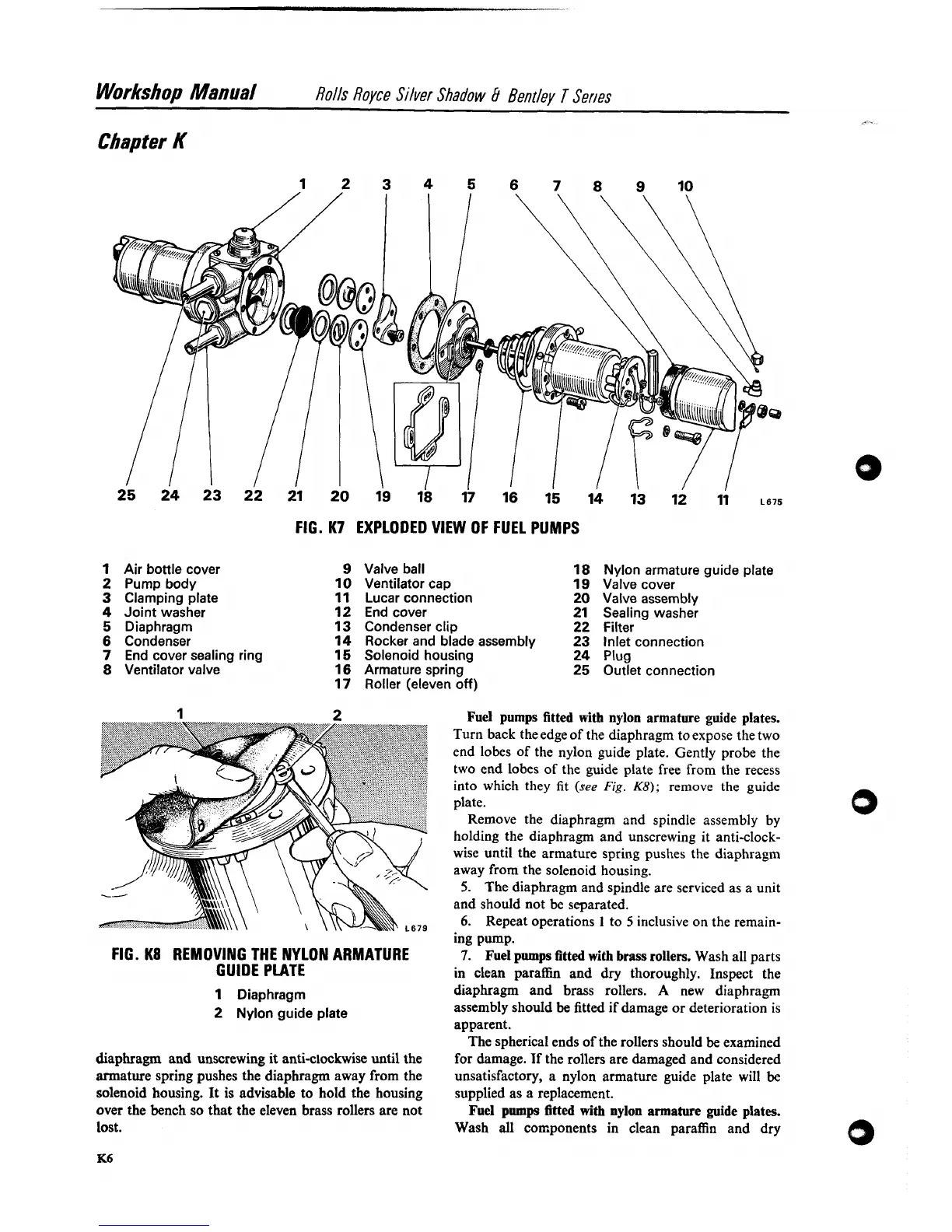

FIG.

K7

EXPLODED VIEW OF FUEL PUMPS

1

Air bottle cover

2

Pump body

3

Clamping plate

4

Joint washer

5

Diaphragm

6

Condenser

7

End cover sealing ring

8

Ventilator valve

9

Valve ball

10

Ventilator cap

11

Lucar connection

12

End cover

13

Condenser clip

14

Rocker and blade assembly

15

Solenoid housing

16

Armature spring

17

Roller (eleven off)

Nylon armature guide plate

Valve cover

Valve assembly

Sealing washer

Filter

Inlet connection

Plug

Outlet connection

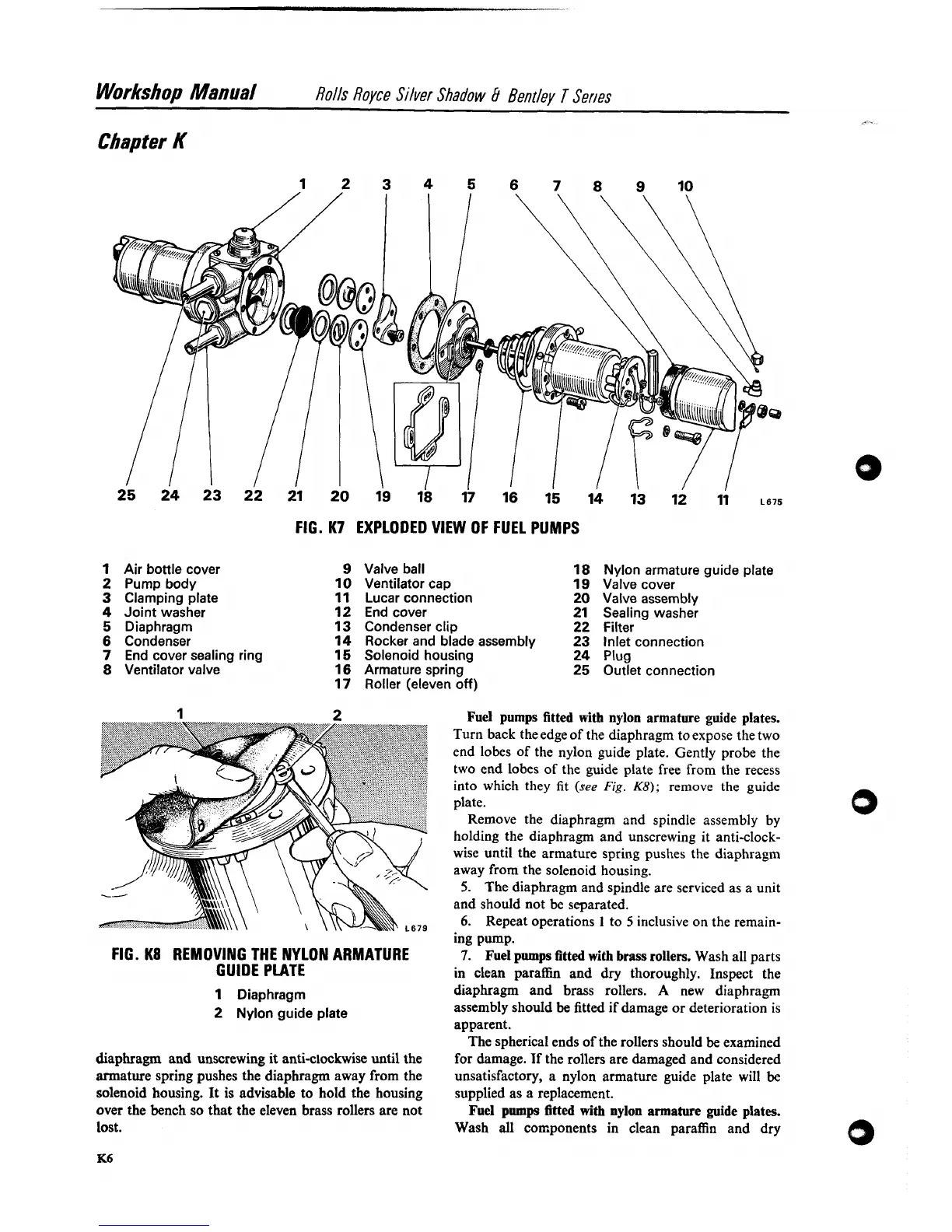

FIG.

K8

REMOVING THE NYLON ARMATURE

GUIDE PLATE

1

Diaphragm

2

Nylon guide plate

diaphragm and unscrewing it

anti-clockwise until the

armature spring pushes the diaphragm away from the

solenoid housing.

It

is advisable to hold the housing

over the bench so that the eleven brass rollers are not

lost.

Fuel pumps fitted with nylon armature guide plates.

Turn back

theedge of the diaphragm to expose the two

end lobes of the nylon guide plate. Gently probe the

two end lobes of the guide plate free from the recess

into which they fit

(see

Fig.

K8);

remove the guide

plate.

Remove the diaphragm and spindle assembly by

holding the diaphragm and unscrewing it anti-clock-

wise until the armature spring pushes the diaphragm

away from the solenoid housing.

5.

The diaphragm and spindle are serviced as a unit

and should not be separated.

6.

Repeat operations

1

to

5

inclusive on the remain-

ing pump.

7.

Fuel pumps

fitted

with brass rollers. Wash all parts

in clean paraffin and

dry thoroughly. Inspect the

diaphragm and brass rollers.

A

new diaphragm

assembly should be fitted if damage or deterioration is

apparent.

The spherical ends of the rollers should

be examined

for damage.

Tf the rollers are damaged and considered

unsatisfactory, a nylon armature guide plate will

be

supplied as a replacement.

Fuel

pumps

fitted

with nylon armature guide plates.

Wash all

coaponents in clean paraffin and dry

Loading...

Loading...