Workshop

Manua/

Rolls Royce Silver Shadow

d

Bentley

T

Series

Chapter

IV

5.

Check the condition of the shaft bearing (bush-

ing).

Note

The bearing is rarely, if evzr, responsible

for noisy pump operation.

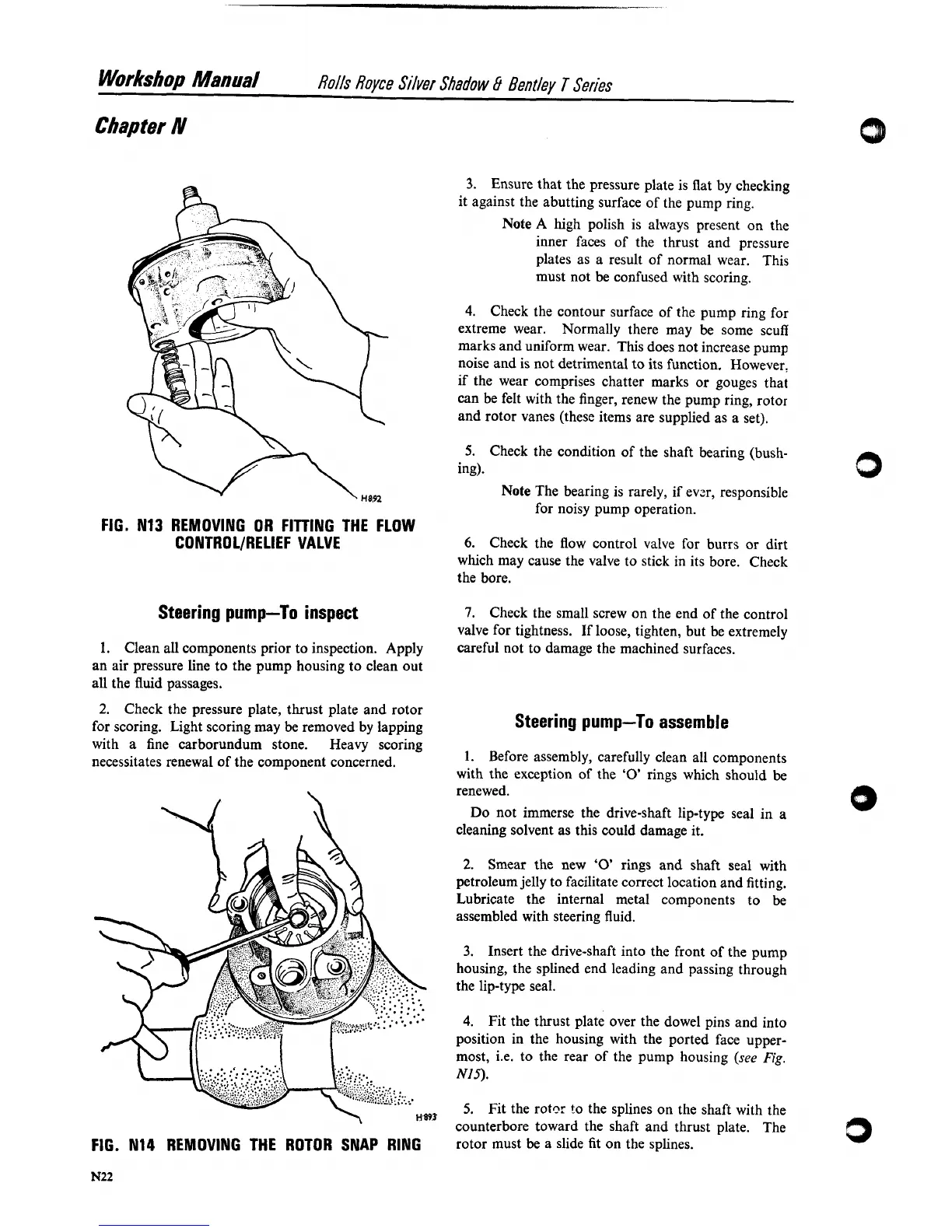

FIG. N13 REMOVING OR FITTING THE FLOW

CONTROL/RELIEF VALVE

Steering pump-To inspect

1.

Clean all components prior to inspection. Apply

an air pressure line to the pump housing to clean out

all the fluid passages.

2.

Check the pressure plate, thrust plate and rotor

for scoring. Light scoring may

be

removed by lapping

with a fine carborundum stone. Heavy scoring

necessitates renewal of the component concerned.

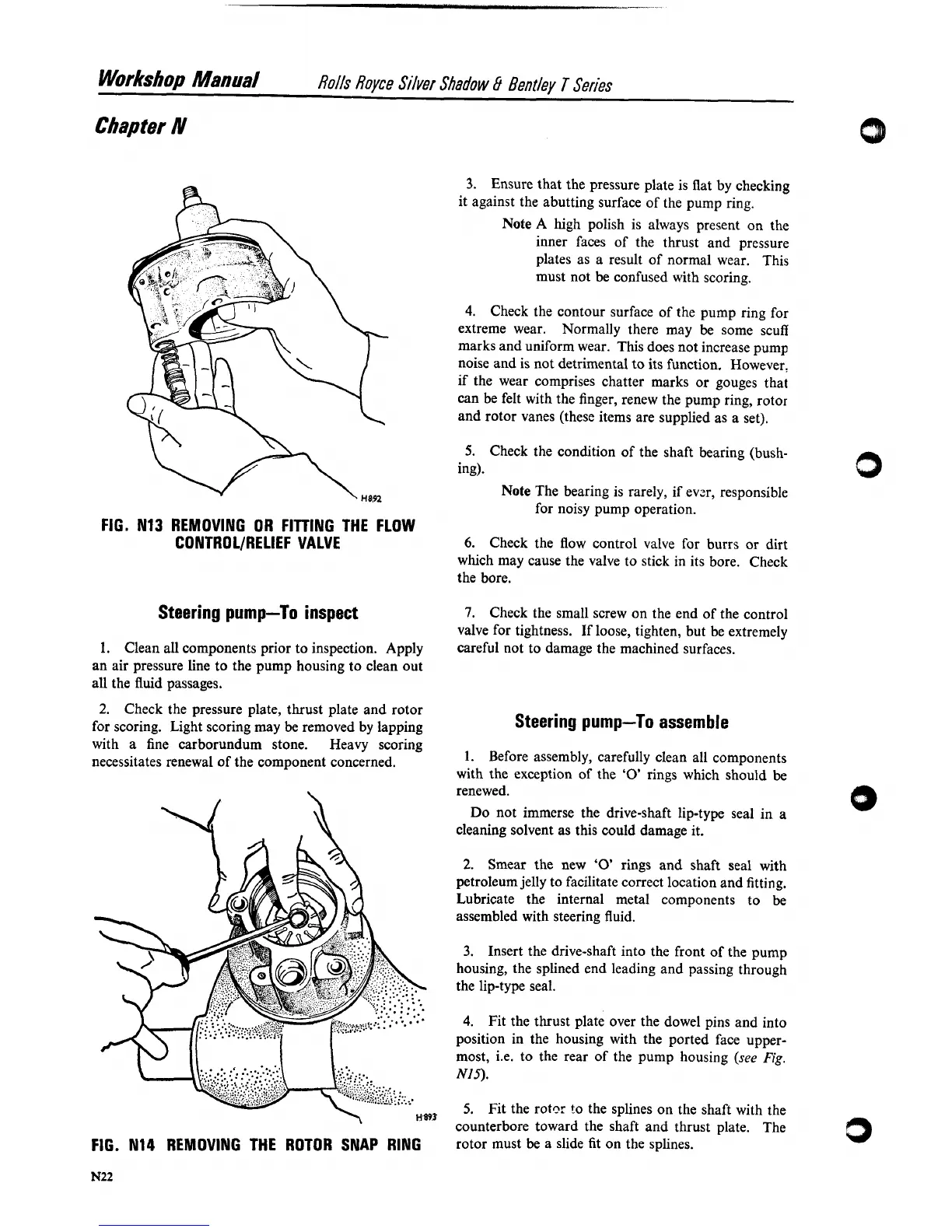

H.893

FIG. N14 REMOVING THE ROTOR SNAP RING

3.

Ensure that the pressure plate is flat by checking

it against the abutting surface of the pump ring.

Note

A

high polish is always present on the

inner faces of the thrust and pressure

plates as a result of normal wear. This

must not be confused with scoring.

4.

Check the contour surface of the pump ring for

extreme wear.

Normally there may be some scuff

marks and uniform wear. This does not increase pump

noise and is not detrimental to its function. However,

if the wear comprises chatter marks or gouges that

can be felt with the finger, renew the pump ring, rotor

and rotor vanes (these items are supplied as a set).

6.

Check the flow control valve for burrs or dirt

which may cause the valve to stick in its bore. Check

the bore.

7.

Check the small screw on the end of the control

valve for tightness. If loose, tighten, but be extremely

careful not to damage the machined surfaces.

Steering pump-To assemble

1.

Before assembly, carefully clean all components

with the exception of the

'0'

rings which should be

renewed.

Do not immerse the drive-shaft lip-type seal in

a

cleaning solvent as this could damage it.

2.

Smear the new

'0'

rings and shaft seal with

petroleum jelly to facilitate correct location and fitting.

Lubricate the internal metal components to be

assembled with steering fluid.

3.

Insert the drive-shaft into the front of the pump

housing, the splined end leading and passing through

the lip-type seal.

4.

Fit the thrust plate over the dowel pins and into

position in the housing with the ported face upper-

most,

i.e. to the rear of the pump housing

(see

Fig.

NIS).

5.

Fit the rotnr to the splines on the shaft with the

counterbore toward the shaft and thrust plate. The

rotor must be a slide fit on the splines.

Loading...

Loading...