Rolls- Royce Silver Shadow

B

Bent/ey

T

Series

Workshop

Manua/

Rear tyres

The rear tyres tend to wear in

a

tapered form from

the outer shoulder across to the inner shoulder; the

centre and inside shoulder showing most wear.

.An

example of a normally worn rear tyre is shown in

Figure

R11.

When assessing tyre wear the following points

should also be considered.

1.

The wear rate on the outer shoulders of the

front and rear tyres which run on the kerb side of

the road will be slightly greater than the other outer

shoulders, particularly if the car is driven on roads

with a pronounced camber.

2.

Tyre wear is critical to tyre inflation pressures,

particularly with respect to under-inflation. There-

fore, it is imperative that the recommended tyre

pressures are maintained.

3.

The higher the speed at which a car is driven

through corners, the more the rear tyres will wear

on the inner shoulders. The effects of hard

cornering will be shown also by the 'feathering'

which occurs on the rib edges as shown in Figure

R11. Do not change the position of a partially worn

set of tyres as the subsequent rate of wear will be

increased.

Tread wear indicators

To provide a visual indication that the depth of

tread remaining on a tyre is 1,6 mm.

($

in.) or less,

tread wear indicators are incorporated into the

construction of the tyres.

These

indicators

are Integrally moulded ribs

located in the tread grooves. The ribs are spaced at

frequent intervals around the circumference of the

tyre and at each point they extend across the full

width of the tyre tread in all primary grooves.

When a tyre has worn so that one or more of the

indicators are flush with the tread (1.6 mm.

(hin.) or less, tread depth)

a

new tyre

is

required.

Remould tyres

In cases where new tyres fail to meet the overall

quality standards laid down by the manufacturers,

but remain structurally sound and are suitable for

sale as a remoulded tyre, the sidewalls will bear

one of the following markings,

'

Regraded Quality',

'Remould Quality' or ~econds'. In addition the

speed rating of the tyre

(e.g. the

H

in HR15) will

be obliterated.

Under no circumstances

should any tyres be

fitted which have

bcen branded 'Regraded Quality',

'

Remould Quality' or "econds', or those which

have had the speed rating removed or altered.

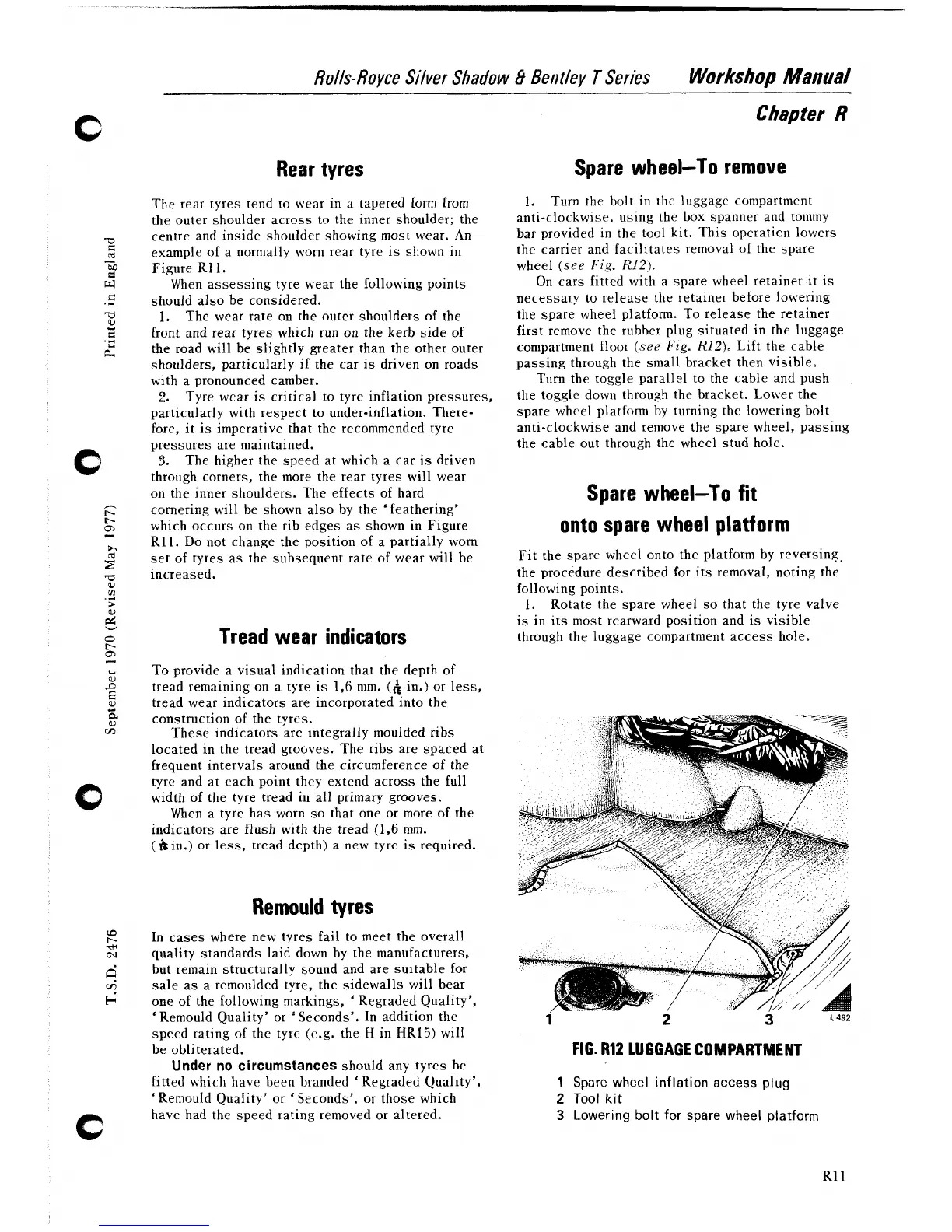

Spare wheel-To remove

1.

Turn the bolt in the luggage

con~partment

anti-clockwise, using the box spanner and tommy

bar provided in the tool kit. This operation lowers

the carrier and facilitates removal of the spare

wheel (see

Fig.

K12).

On cars fitted with a spare wheel retainer it is

necessary to release the retainer before lowering

the spare wheel platform. To release the retainer

first remove the rubber plug situated in the luggage

compartment floor (see

Fig.

R12).

Lift the cable

passing through the small bracket then visible.

Turn the toggle parallel to the cable and push

the toggle down through the bracket. Lower the

spare wheel

platforn~ by turning the lowering bolt

anti-clockwise and remove the spare wheel, passing

the cable out through the wheel stud hole.

Spare wheel-To fit

onto spare wheel platform

Fit the spare wheel onto the platform by reversing-

the procedure described for its removal, noting the

following points.

1.

Rotate the spare wheel so that the tyre valve

is in its most rearward position and is visible

through the luggage compartment access hole.

1

2

3

L

492

FIG.

R12

LUGGAGE

COMPARTMENT

1

Spare wheel inflation access

plug

2

Tool

kit

3

Lowering bolt

for

spare wheel platform

Loading...

Loading...