Workshop

Manual

Rolls Royce Silver Shadow

d

Bentley

T

Series

Chapter

N

2.

Inspect the high and low pressure line hose

connector seats, the poppet valve and seat in the

steering box housing. Renew if they are badly scored,

cracked or distorted.

3.

Inspect the ball plug in the valve body end of the

housing. If it is leaking or raised above the surface

it should be seated flush or

&

in. (1,59

rnm.)

below

the surface.

Lightly

peen over the end of the bore to

secure the ball.

2.

Tap threads in the connector seats using a

I$

in.

thread tap.

Note

Do not tap threads too deeply in the

pressure hose connector seat as the tap

will bottom the poppet valve against the

housing and damage it. It is necessary

to tap only

2

or

3

threads deep.

3. Insert a

&

in. threaded bolt with a nut and

suitable flat washer into the tapped hole (see

Fig.

N27).

4.

To extract the connector seat, prevent the bolt

4.

Inspect all retaining ring grooves and seal sur-

from rotating while screwing the nut off the bolt. This

faces for damage or failure.

will extract the connector from the housing. Discard

the connector seat.

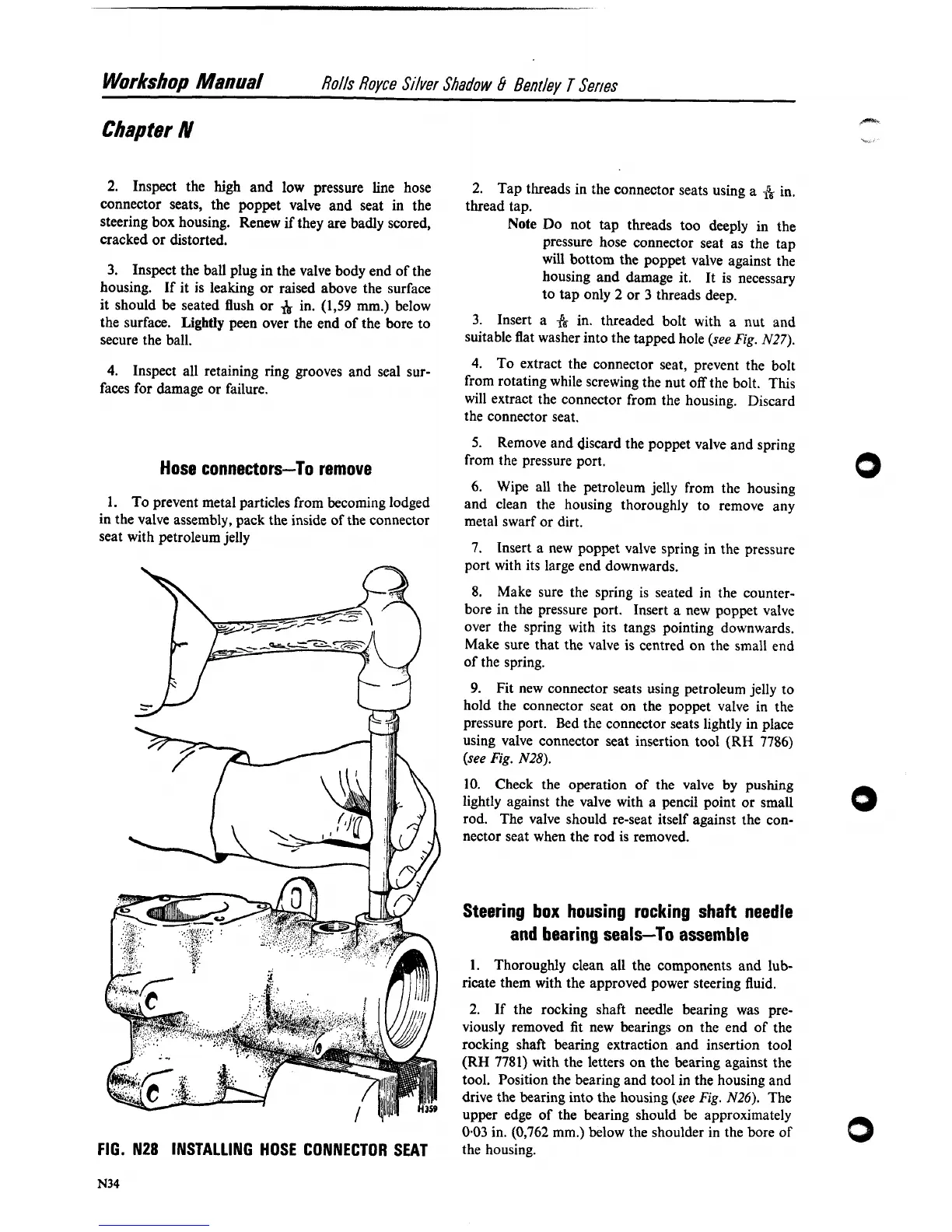

Hose connectors-To remove

1. To prevent metal particles from becoming lodged

in the valve assembly, pack the inside of the connector

seat with petroleum jelly

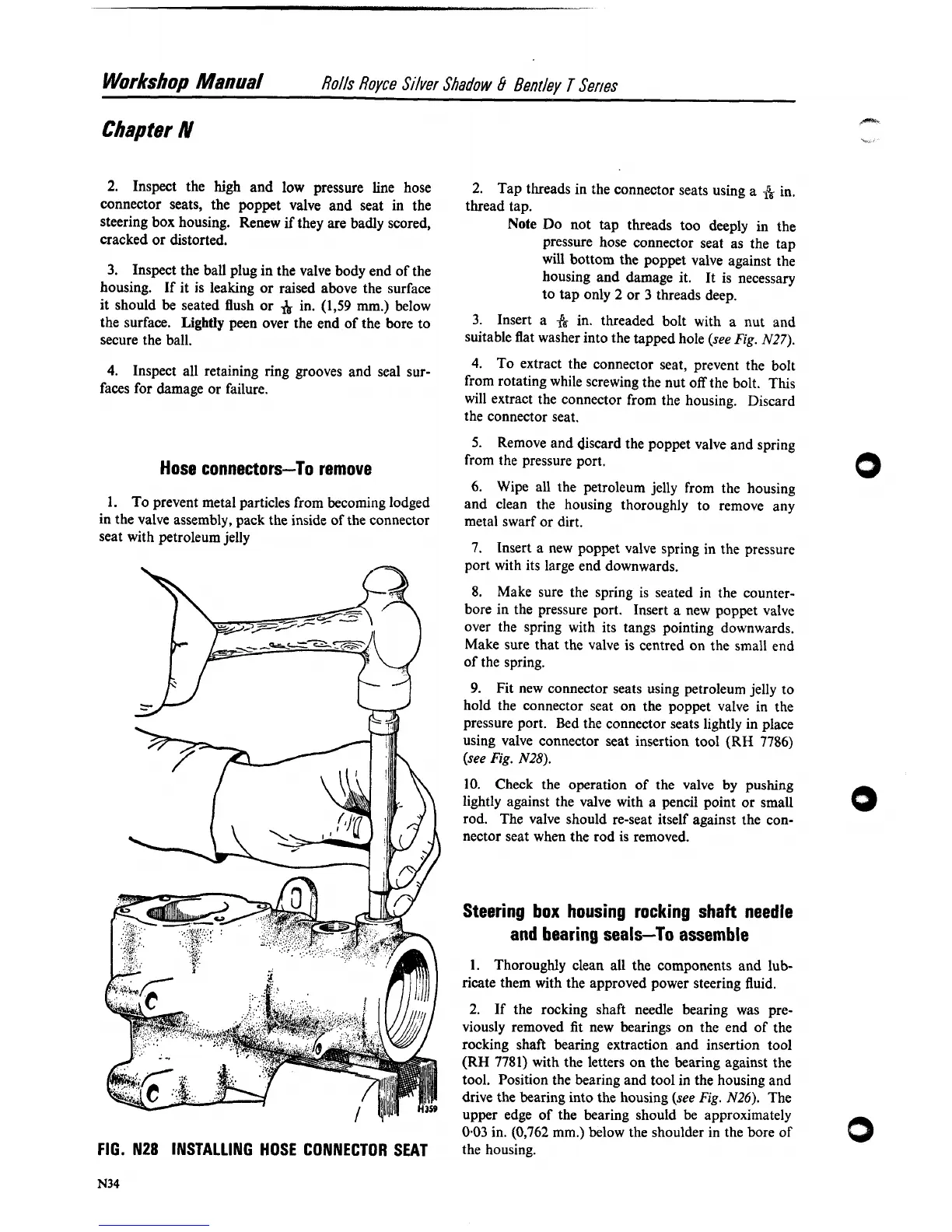

FIG. N28 INSTALLING HOSE CONNECTOR SEAT

5.

Remove and discard the poppet valve and spring

from the pressure port.

6.

Wipe all the petroleum jelly from the housing

and clean the housing thoroughly to remove any

metal swarf or dirt.

7.

Insert a new poppet valve spring in the pressure

port with its large end downwards.

8.

Make sure the spring is seated in the counter-

bore in the pressure port. Insert

a

new poppet valve

over the spring with its tangs pointing downwards.

Make sure that the valve is centred on the small end

of the spring.

9. Fit new connector seats using petroleum jelly to

hold the connector seat on the poppet valve in the

pressure port. Bed the connector seats lightly in place

using valve connector seat insertion tool

(RH

7786)

(see

Fig.

N28).

10. Check the operation of the valve by pushing

lightly against the valve with a pencil point or small

rod. The valve should re-seat itself against the con-

nector seat when the rod is removed.

Steering box housing rocking shaft needle

and bearing seals--To assemble

1.

Thoroughly clean all the components and lub-

ricate them with the approved power steering fluid.

2.

If the rocking shaft needle bearing was pre-

viously removed fit new bearings on the end of the

rocking shaft bearing extraction and insertion tool

(RH

7781)

with the letters on the bearing against the

tool. Position the bearing and tool in the housing and

drive the bearing into the housing (see

Fig.

N26).

The

upper edge of the bearing should be approximately

0.03 in. (0,762 mm.) below the shoulder in the bore of

the housing.

0

Loading...

Loading...