Workshop

Manual

Rolls Royce

Silver

Shadow

b

Bentlev

i

Series

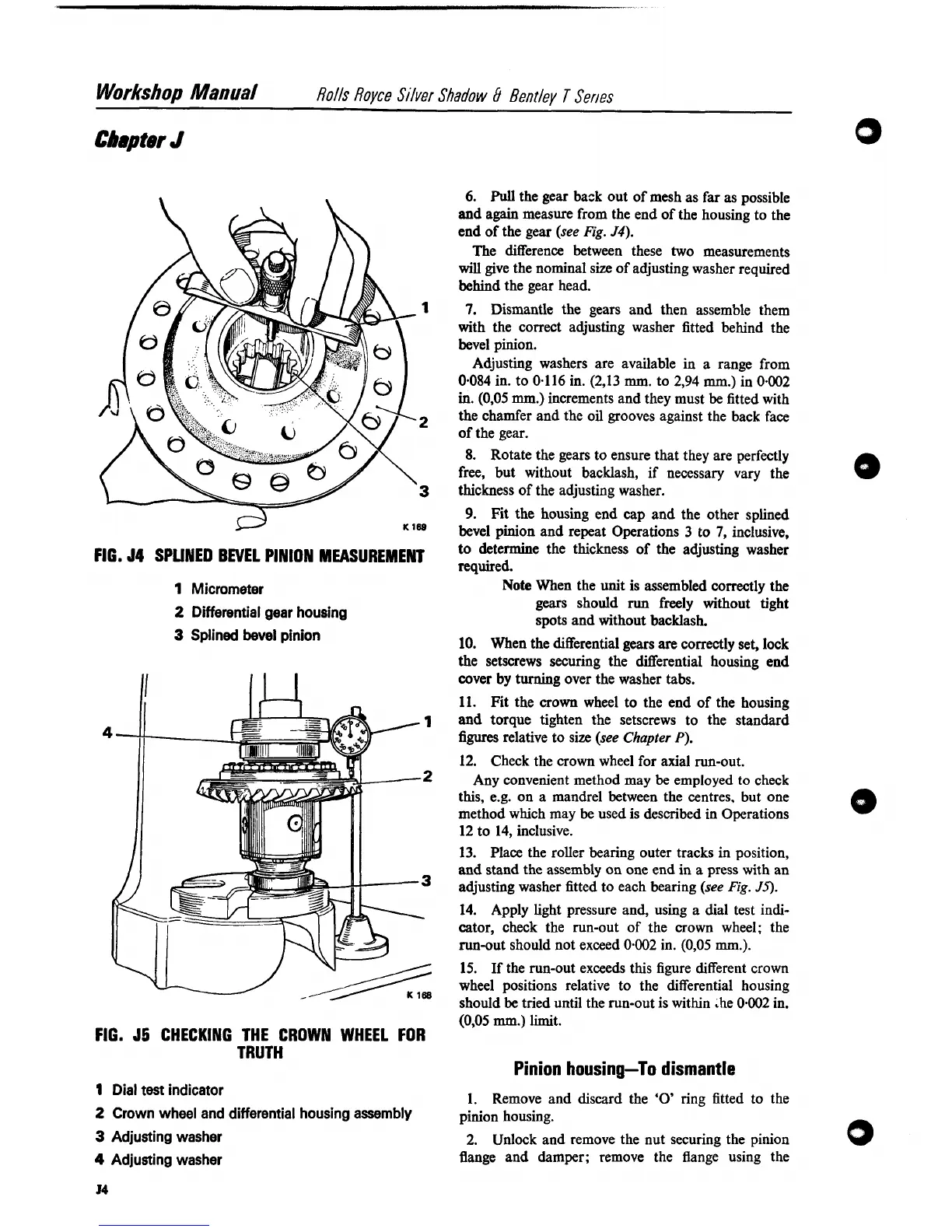

6.

Pull

the gear bask out of mesh as far as possible

and again measure from the end of the housing to the

end of the gear (see

Fig.

J4).

The difference between these two measurements

will

give the nominal size of adjusting washer required

behind the gear head.

7.

Dismantle the gears and then assemble them

with the correct adjusting washer fitted behind the

bevel pinion.

Adjusting washers are available in a range from

0.084 in. to 0.116 in.

(2,13

mm.

to

2,94

mm.)

in

0.002

in. (0,05

mm.)

increments and they must be fitted with

the chamfer and the oil grooves against the back face

of the gear.

8.

Rotate the gears to ensure that they are perfectly

free, but without backlash, if necessary vary the

thickness of the adjusting washer.

FIG.

J4

SPUNED BEVEL PINION MEASUREMENT

1

Micrometer

2

Differential gear housing

3

Splined bevel pinion

ILL

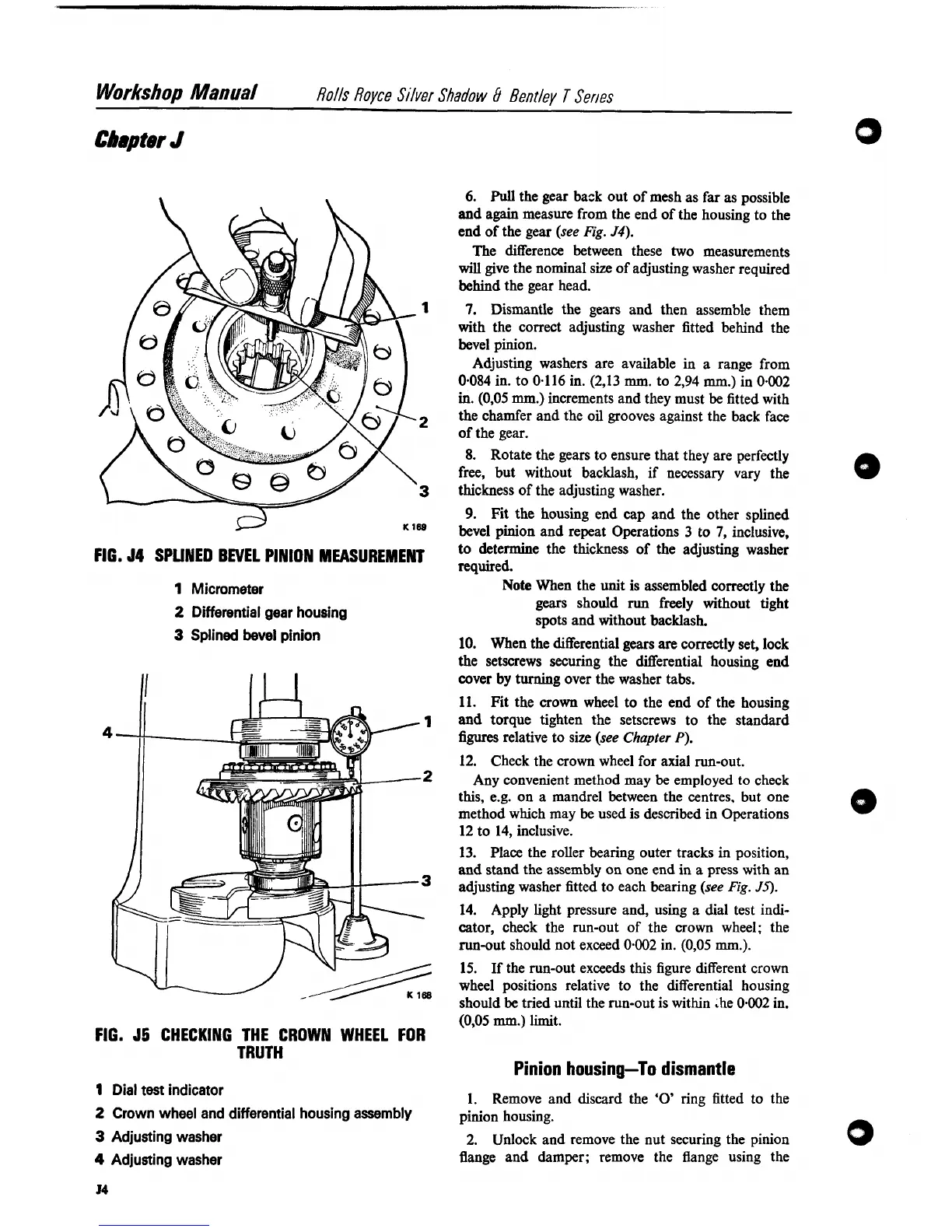

FIG.

55

CHECKING THE CROWN WHEEL

FOR

TRUTH

1

Dial test indicator

2

Crown wheel and differential housing assembly

3

Adjusting washer

4

Adjusting washer

9.

Fit the housing end cap and the other splined

bevel pinion and repeat Operations 3 to

7,

inclusive,

to determine the thickness of the adjusting washer

required.

Note

When the unit is assembled correctly the

gears should

run

freely without tight

spots and without backlash.

10. When the differential gears

are

correctly set, lock

the setscrews securing the differential housing end

cover

by

turning over the washer tabs.

11. Fit the crown wheel to the end of the housing

and torque tighten the setscrews to the standard

figures relative to size (see Chapter

P).

12.

Check the crown wheel for axial run-out.

Any convenient method may

be

employed to check

this,

e.g. on a mandrel between the centres, but one

method which may be used is described in Operations

12

to 14, inclusive.

13. Place the roller bearing outer tracks in position,

and stand the assembly on one end in a press with an

adjusting washer fitted to each bearing (see

Fig.

J5).

14. Apply light pressure and, using

a

dial test indi-

cator, check the run-out of the crown wheel; the

run-out should not exceed

0.002

in.

(0,05

mm.).

15.

If

the run-out exceeds this figure different crown

wheel positions relative to the differential housing

should

be

tried until the run-out is within &he

0.002

in.

(0,05

mm.)

limit.

Pinion housing-To dismantle

1. Remove and discard the

'0'

ring fitted to the

pinion housing.

2.

Unlock and remove the nut securing the pinion

flange and damper; remove the flange using the

Loading...

Loading...