Rolls- Royce Silver Shadow

8

Bentley

T

Series

Workshop

Wua/

Chapter

L

Coolant pump

-

To dismantle

1

2

3

For normal service operation, the bearing housing

will have already been separated from the pump

a

casing.

9

A

1.

Draw the impeller off the shaft using the

M

c

special tool (RH 7098).

W

E

2. Remove the peg screw which retains the

.-

bearing in the housing.

-z

,d

3.

Support the bearing housing to enable the

.

a

bearing assembly to be lightly driven out with a

PI

mallet.

4.

Remove and discard the seal and counter

face.

5.

Examine the shaft and bearing for wear and

damage. The assembly contains lubricant there-

fore no attempt must be made to wash any of the

components.

6.

If the

spider

(early cars),

flange

(later cars)

or the shaft has been damaged, draw the component

off the shaft using the following special tool.

S

583

Spider

-

(RH 7099)

Flange

-

(RH 8615)

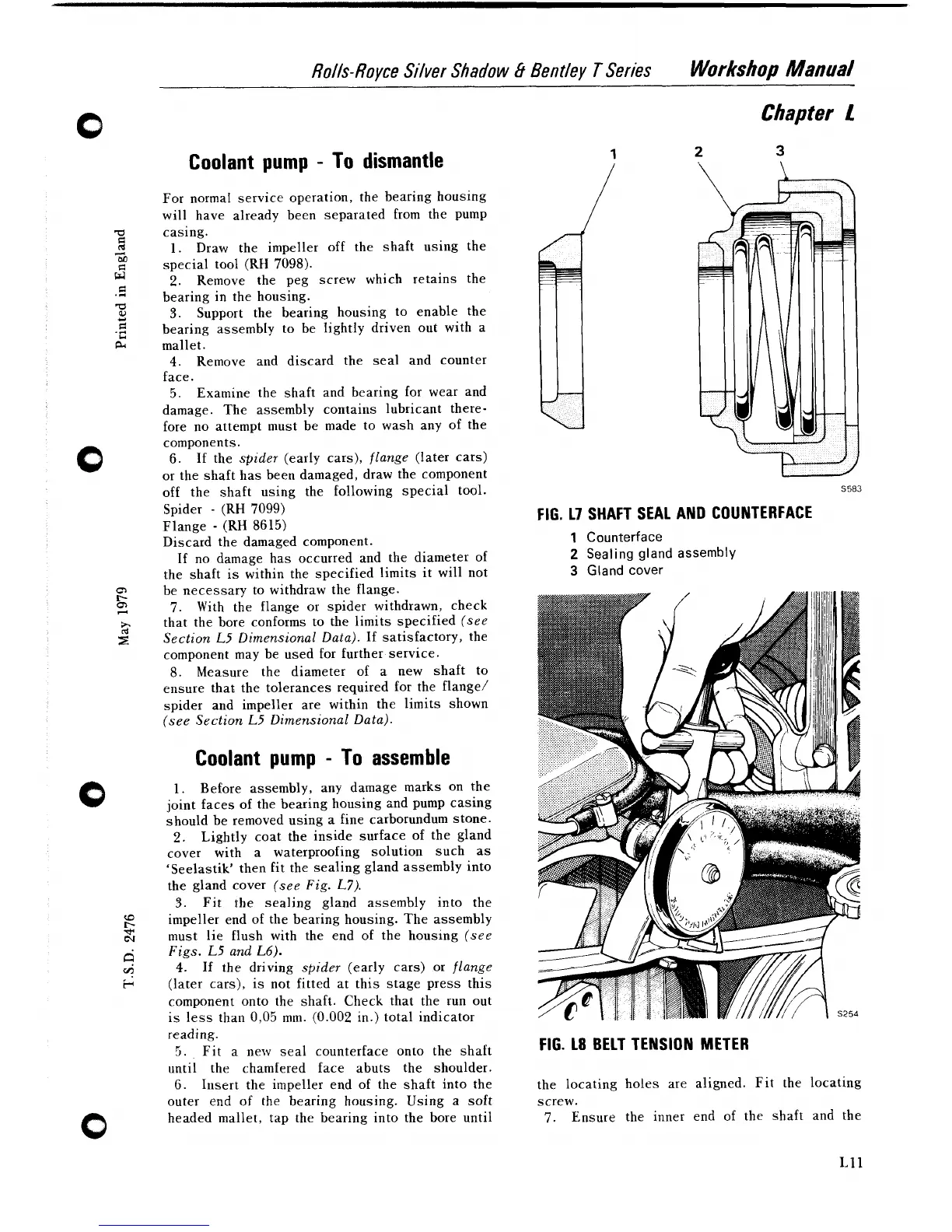

FIG. 17 SHAFT SEAL AND COUNTERFACE

Discard the damaged component.

1

Counterface

If no damage has occurred and the diameter of

2

Sealing gland assembly

the shaft is within the specified limits it will not

3

Gland cover

be necessary to withdraw the flange.

7.

With the flange or spider withdrawn, check

that the bore conforms to the limits specified

(see

Section

L5

Dimensional Data).

If satisfactory, the

component may be used for further service.

8. Measure the diameter of a new shaft to

ensure that the tolerances required for the

flange/

spider and impeller are within the limits shown

(see Section

L5

Dimensional Data).

Coolant pump

-

To

assemble

1.

Before assembly, any damage marks on the

joint faces of the bearing housing and pump casing

should be removed using a fine carborundum stone.

2.

Lightly coat the inside surface of the gland

cover with a waterproofing solution such as

'Seelastik' then fit the sealing gland assembly into

the gland cover

(see Fig.

L7).

3.

Fit the sealing gland assembly into the

impeller end of the bearing housing. The assembly

must lie flush with the end of the housing

(see

Figs.

L5

and

L6).

4.

If

the driving

spider

(early cars) or

flange

(later cars), is not fitted at this stage press this

component onto the shaft. Check that the run out

is less than

0,05 mm. (0.002 in.) total indicator

reading.

5.

Fit a new seal counterface onto the shaft

FIG. 18 BELT TENSION METER

until the chamfered face abuts the shoulder.

6.

Insert the impeller end of the shaft into the the locating holes are aligned. Fit the locating

outer end of the bearing housing. Using a soft screw.

headed mallet, tap the bearing into the bore until

7. Ensure the inner end of the shaft and the

Loading...

Loading...