Rolls-Royce Silver

Shadow

B

Bentley

T

Series

Workshop

Manual

C

Chapter

M

.3.

.Press the old bearing out of the bracket.

4.

Before fitting the new bearing, ensure that it

is clean and packed with an approved melting-point

grease.

5.

Locate the bearing in the housing and press

C

.

-

n

squarely into position.

-

-

d

6.

When fitting the bearing retaining plate, use

-

*

I

new rivets.

C?

..

Alternator output control unit Model

4

TR

F

E

.-

h

Important

The battery must never be dis-

n.

connected while the alternator is

running. Failure to observe this

ruling will cause the control unit to

be damaged.

Checking and adjusting

1.

Before checking and adjusting the control unit

it must be established that the alternator and the

charging circuit wiring are in good condition.

2.

Check the battery to control unit wiring which

incorporates the field isolating relay. To ensure

correct working of the control unit, the resistance of

this complete circuit, including the isolating relay,

must not exceed

0.1

ohm. Any unduly high resistance

must be traced and rectified.

C

6

-

6

E

$

z

Control unit-To check

Do not disturb the existing connections to the alter-

nator and control unit.

1.

Connect a voltmeter of the suppressed-zero

type, reading

12

Volt to

15

Volt between the battery

terminals and note the reading with all electrical

equipment switched off.

2.

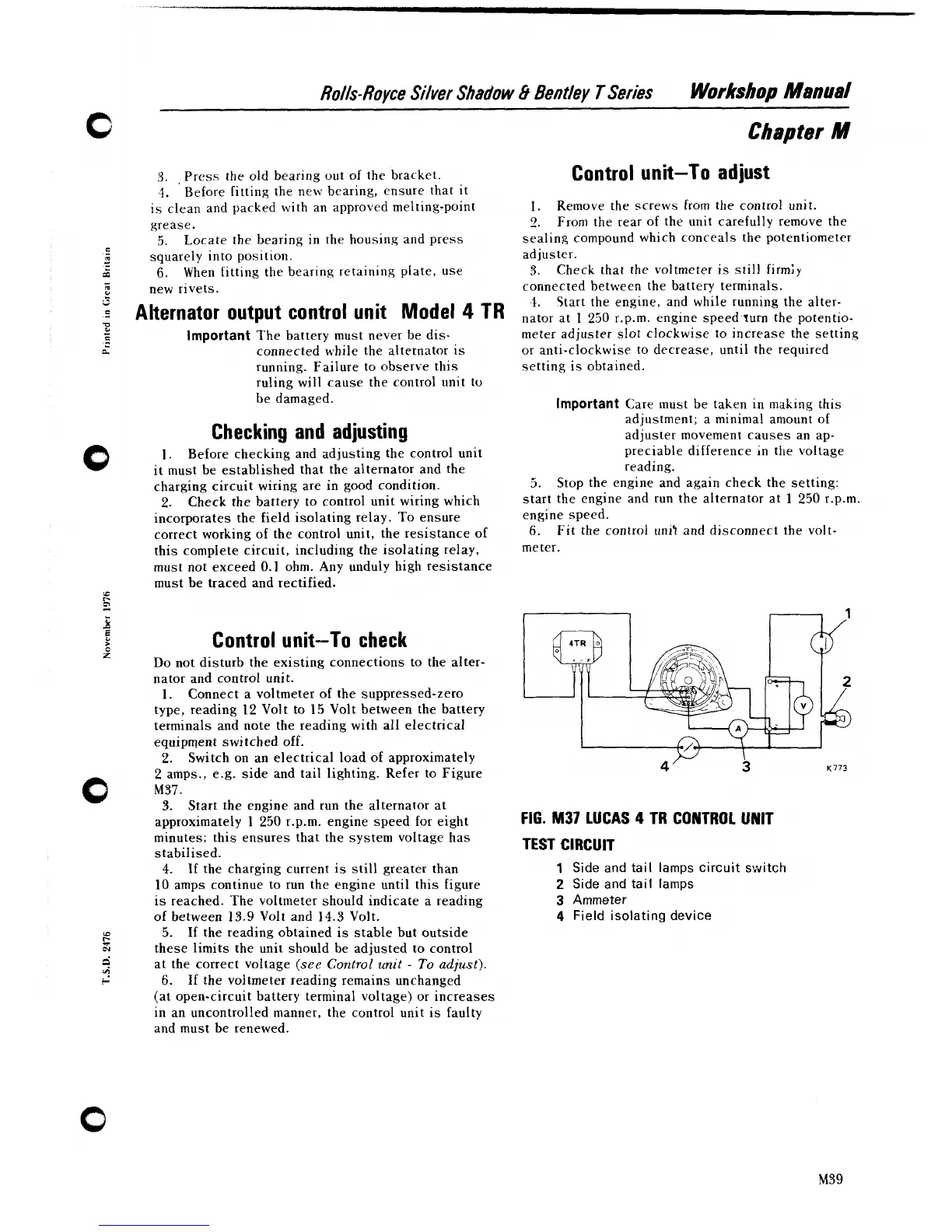

Switch on an electrical load of approximately

2

amps., e.g. side and tail lighting. Refer to Figure

0

M37.

3.

Start the engine and run the alternator at

approximately

1

250

r.p.m. engine speed for eight

Control unit-To adjust

1.

Remove the screws from the control unit.

2.

From the rear of the unit carefully remove the

sealing compound which conceals the potentiometer

adjuster.

3.

Check that the voltmeter

is

still firmly

connected between the battery terminals.

,I.

Start the engine, and while running the alter-

nator at

1

250

r.p.m. engine speed.turn the potentio-

meter adjuster slot clockwise to increase the setting

or anti-clockwise to decrease, until the required

setting is obtained.

Important

Care must be taken in making this

adjustment; a minimal amount of

adjuster movement causes an ap-

preciable difference

;n the voltage

reading.

5.

Stop the engine and again check the setting:

start the engine and run the alternator at

1

250

r.p.m.

engine speed.

6.

Fit the control unit and disconnect the volt-

meter.

4'

3

K773

FIG.

M37

LUCAS

4

TR

CONTROL UNIT

minutes; this ensures that the system voltage has

stabilised.

TEST CIRCUIT

4.

If

the charging current is still greater than

1

Side and tail lamps circuit switch

10

amps continue to run the engine until this figure

2

Side and tail lamps

is reached. The voltmeter should indicate a reading

3

Ammeter

of between

13.9

Volt and

14.3

Volt.

4

Field isolating device

iD

I-

3

5.

If the reading obtained is stable but outside

N

these limits the unit should be adjusted to control

?'

at the correct voltage

(see

Control unit

-

To

adjust).

"?

t-

6.

If the voltmeter reading remains unchanged

(at open-circuit battery terminal voltage) or increases

in an uncontrolled manner, the control unit is faulty

and must be renewed.

Loading...

Loading...