Workshop

Manual

Rolls- Royce Silver Shadow

&

Bentley

T

Series

Chapter

M

2.

Remove foreign material from rotor shaft and

stator using a clean cioth moistened with white

spirit.

Caution

Spirit should not be allowed to

contact the leads of the stator and

must not contaminate the protective

coating of the rotor core.

3.

Examine the stator windings for security and

condition. Check the insulation of the stator leads

for deterioration.

4.

Check the bearings for excessive play and

smoothness of operation. The bearings are sealed

and cannot be lubricated therefore any evidence of

dryness will necessitate renewal. If the SRE

bearing requires replacement it will also be

necessary to renew the slip ring.

5.

Examine the slip rings for signs of wear and

scoring. The slip rings may be skimmed to a

minimum diameter of

28,5

mm. (1.136 in.) before

replacement is necessary.

6.

Check carbon brushes for wear. New brushes

are

15,9 rnm. long

(0.625

in.) and the minimum

length of usable brushes is

7,9

mm.

(0.312

in.).

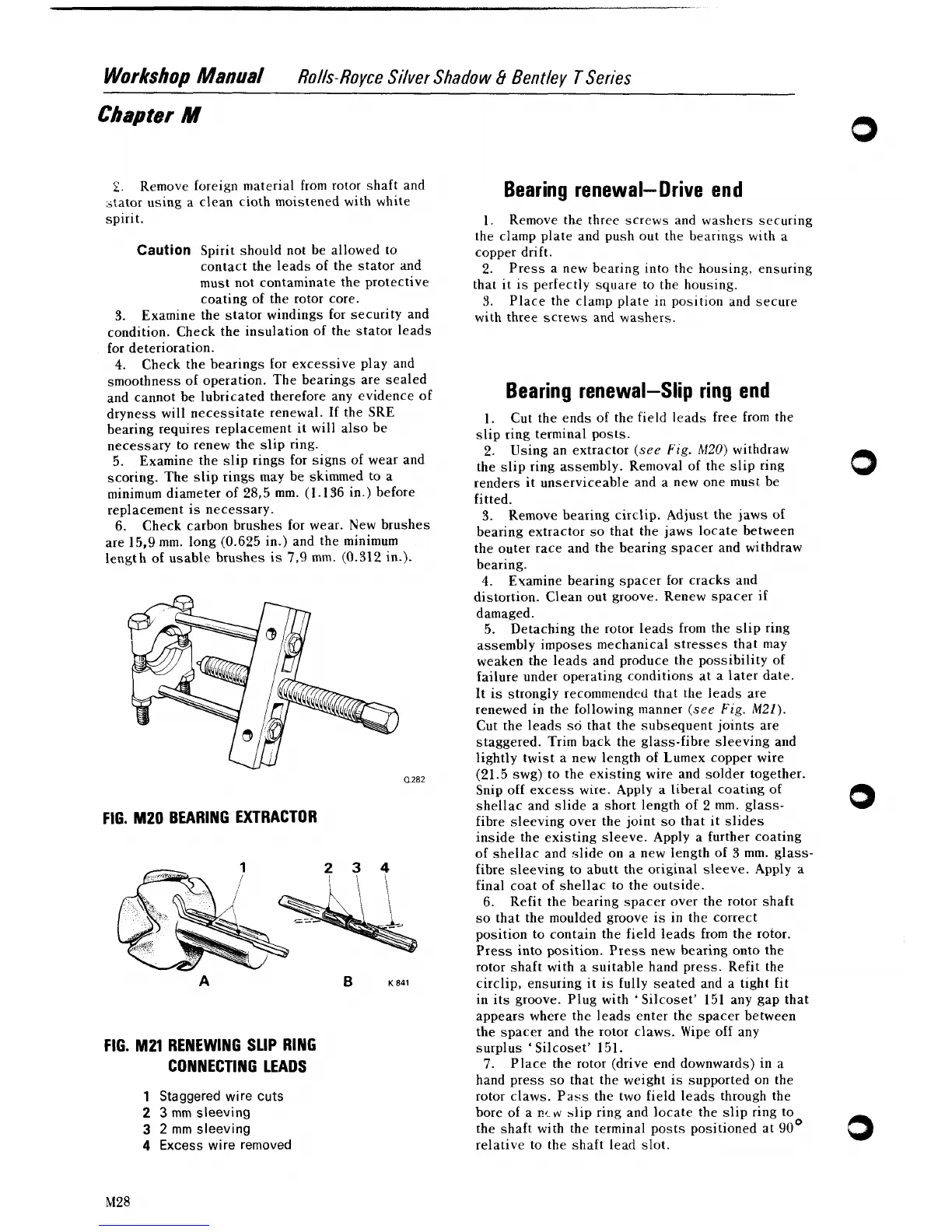

FIG.

M20

BEARING EXTRACTOR

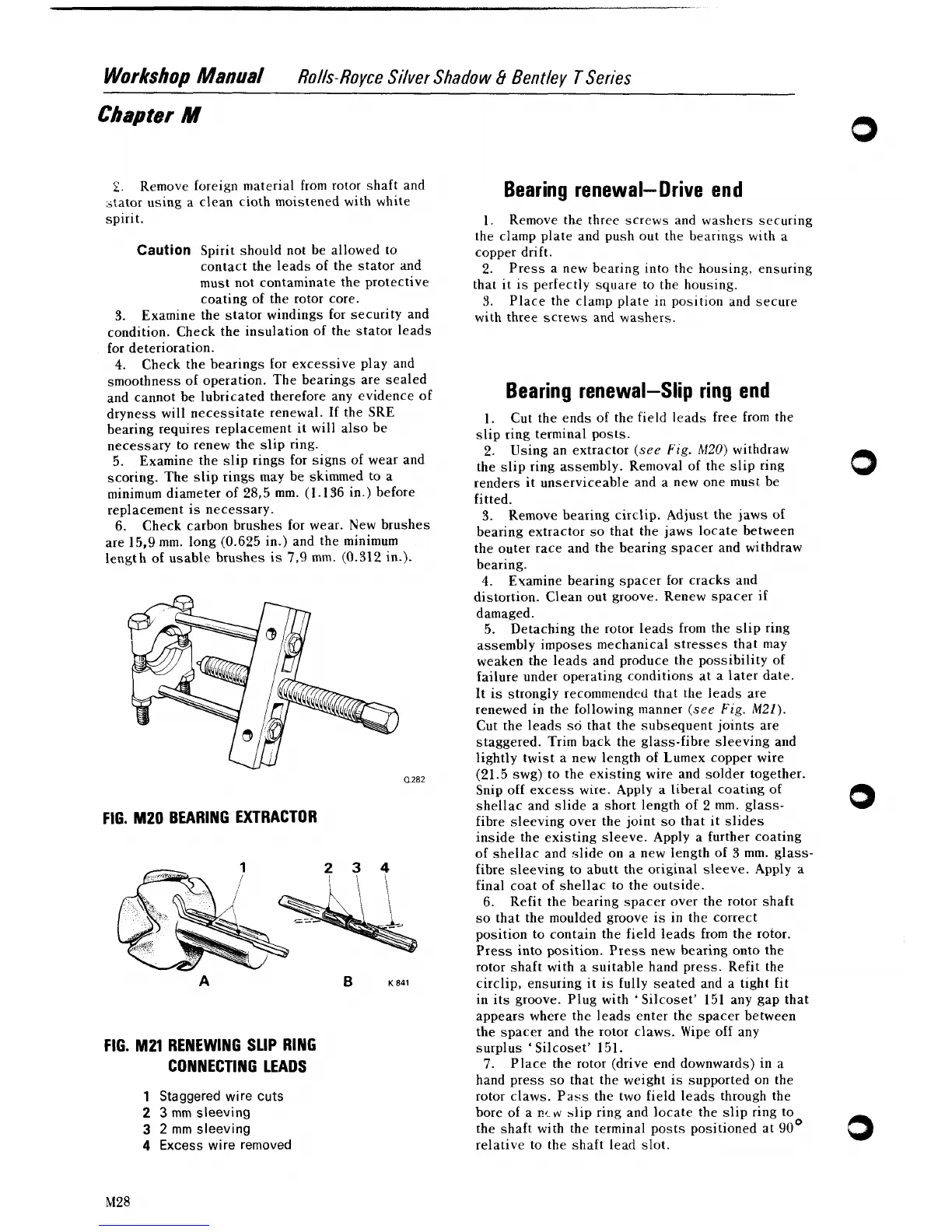

FIG.

M21

RENEWING SLIP RING

CONNECTING LEADS

1

Staggered wire cuts

2

3

mm

sleeving

3

2

mm

sleeving

4

Excess wire removed

Bearing renewal-Drive end

1.

Remove

the three screws and washers securing

the clamp plate and push out the bearings with a

copper drift.

2.

Press a new bearing into the housing, ensuring

that it is perfectly square to the housing.

3.

Place the clamp plate in position and secure

with three screws and washers.

Bearing renewal-Slip ring end

1.

Cut the ends of the field leads free from the

slip ring terminal posts.

2.

Using an extractor

(see

Fig.

12.120)

withdraw

the slip ring assembly. Removal of the slip ring

renders it unserviceable and a new one must be

fitted.

3.

Remove bearing circlip. Adjust the jaws of

bearing extractor so that the jaws locate between

the outer race and the bearing spacer and withdraw

bearing.

4.

Examine bearing spacer for cracks and

distortion. Clean out groove. Renew spacer if

damaged.

5.

Detaching the rotor leads from the slip ring

assembly imposes mechanical stresses that may

weaken the leads and produce the possibility of

failure under operating conditions at a later date.

It is strongly recommended that the leads are

renewed in the following manner

(see

Fig.

M21).

Cut the leads s6 that the subsequent joints are

staggered. Trim back the glass-fibre sleeving and

lightly twist a new length of Lumex copper wire

(21.5 swg) to the existing wire and solder together.

Snip off excess wire. Apply

a

liberal coating of

shellac and slide a short length of

2

mm. glass-

fibre sleeving over the joint so that it slides

0

inside the existing sleeve. Apply a further coating

of shellac and

slide on

a

new length of

3

mm. glass-

fibre sleeving to abutt the original sleeve. Apply a

final coat of shellac to the outside.

6.

Refit the bearing spacer over the rotor shaft

so that the moulded groove is in the correct

position to contain the field leads from the rotor.

Press into position. Press new bearing onto the

rotor shaft with a suitable hand press. Refit the

circlip, ensuring it is fully seated and a tight fit

in its groove. Plug with 'Silcoset' 151 any gap that

appears where the leads enter the spacer between

the spacer and the rotor claws. Wipe off any

surplus

'

Silcoset' 151.

7.

Place the rotor (drive end downwards) in a

hand press so that the weight is supported on the

rotor claws. Pass the two field leads through the

-

bore of a

~cw

blip ring and locate the slip ring to

the shaft with the terminal posts positioned

at

90'

3

relative to the shaft lead slot.

Loading...

Loading...