Rolls-Royce Silver Shadow

B

Bentley

T

Series

Workshop

Manual

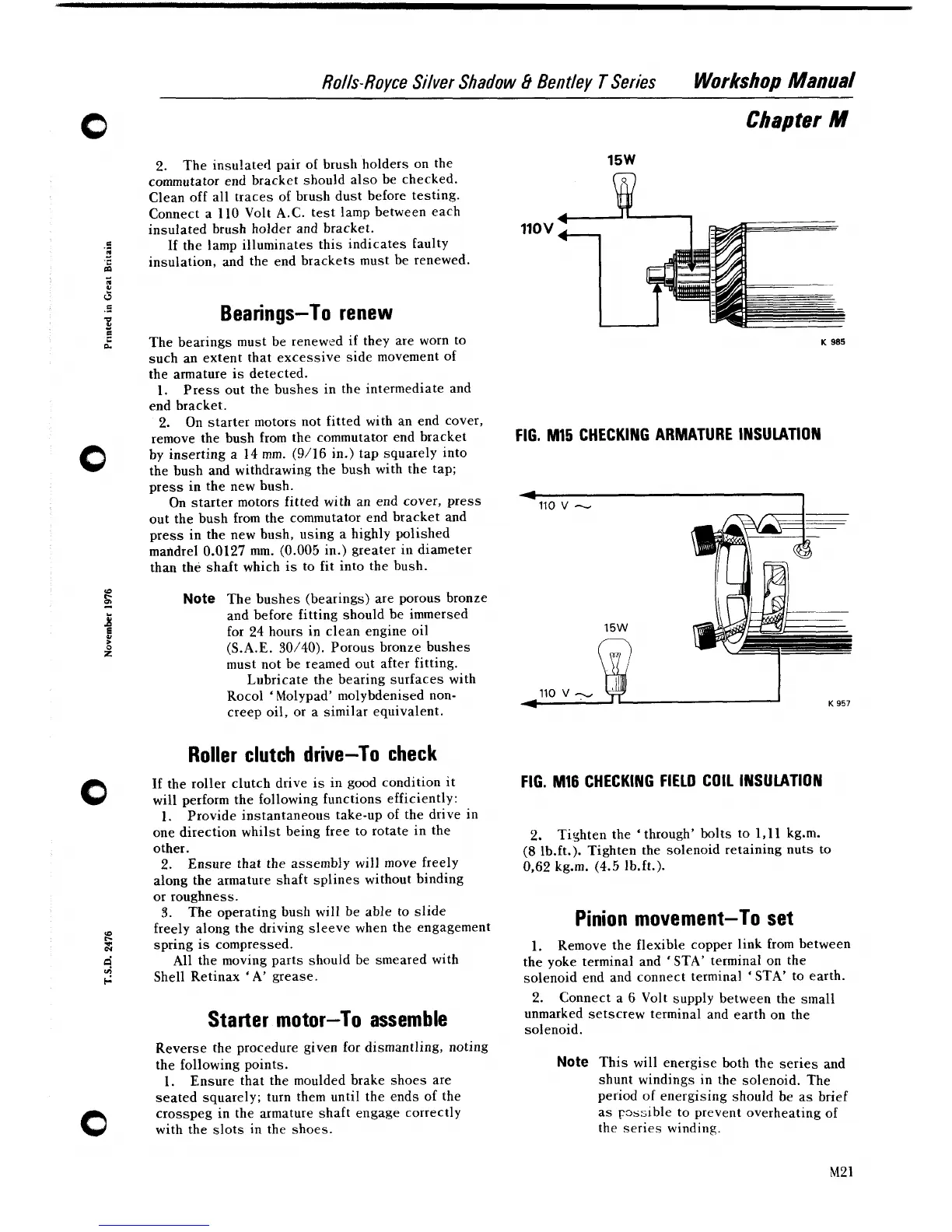

2.

The insu!aterl pair of brush holders on the

commutator end bracket should also be checked.

Clean off all traces of brush dust before testing.

Connect a 110 Volt A.C. test lamp between each

insulated brush holder and bracket.

If the lamp illuminates this indicates faulty

insulation, and the end brackets must be renewed.

Bearings-To renew

The bearings must be renewed if they are worn to

such an extent that excessive side movement of

the armature is detected.

1.

Press out the bushes in the intermediate and

end bracket.

2.

On starter motors not fitted with an end cover,

remove the bush from the commutator end bracket

by inserting a 14 mm.

(9/16 in.) tap squarely into

the bush and withdrawing the bush with the tap;

press in the new bush.

On starter motors fitted with an end cover, press

out the bush from the commutator end bracket and

press in the new bush, using a highly polished

maadre1 0.0127 mm. (0.005 in.) greater in diameter

than the shaft which is to fit into the bush.

Note

The bushes (bearings) are porous bronze

and before fitting should be immersed

for 24 hours in clean engine oil

(S.A.E.

30/40). Porous bronze bushes

must not be reamed out after fitting.

Lubricate the bearing surfaces with

Roc01

'

Molypad' molybdenised non-

creep oil, or a similar equivalent.

Roller clutch drive-To check

If the roller clutch drive is in good condition it

will perform the following functions efficiently:

1.

Provide instantaneous take-up of the drive in

one direction whilst being free to rotate in the

other.

2.

Ensure that the assembly will move freely

along the armature shaft splines without binding

or roughness.

3.

The operating bush will be able to slide

freely along the driving sleeve when the engagement

spring is compressed.

All the moving parts should be smeared with

Shell

Retinax 'A' grease.

Starter motor-To assemble

Reverse the procedure given for dismantling, noting

the following points.

1.

Ensure that the moulded brake shoes are

seated squarely; turn them until the ends of the

crosspeg in the armature shaft engage correctly

with the slots in the shoes.

Chapter

M

FIG. MI5 CHECKING ARMATURE INSULATION

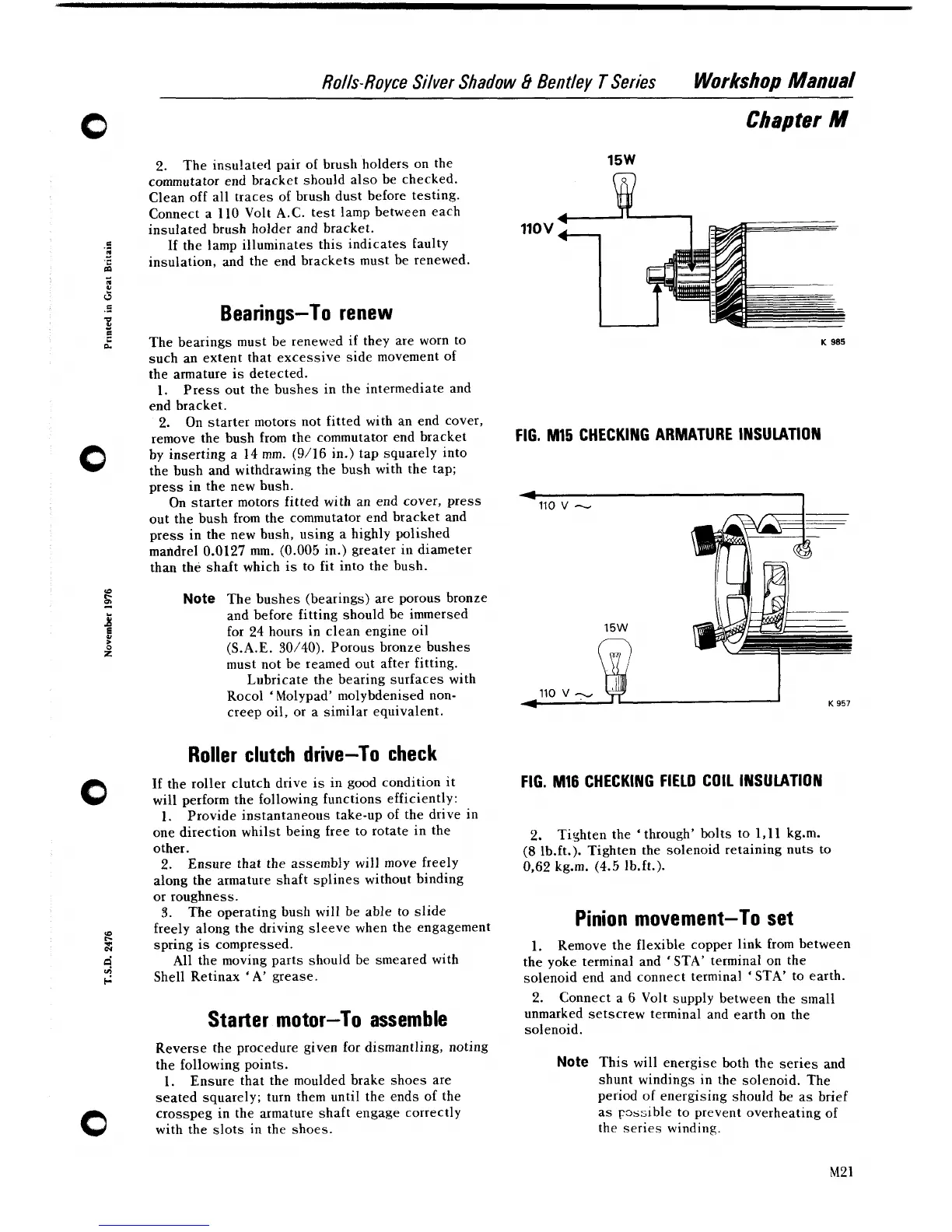

FIG.

MI6 CHECKING FIELD COIL INSULATION

2.

Tishten the

'

through' bolts to 1,11 kg.m.

(8

1b.ft.). Tighten the solenoid retaining nuts to

0,62

kg.m. (4.5 1b.ft.).

Pinion movement-To set

1.

Remove the flexible copper link from between

the yoke terminal and

'

STA' terminal on the

solenoid end and connect terminal

'

STA' to earth.

2.

Connect a 6 Volt supply between the small

unmarked setscrew terminal and earth on the

solenoid.

Note

This will energise both the series and

shunt windings in the solenoid. The

period

of

energising should be as brief

as

passible to prevent overheating of

the series winding.

Loading...

Loading...