Rolls-Royce Silver Shadow

B

Bentley

T

Series

Workshop

Manual

C

Chapter

M

4.

The voltage should rise steadily and then

drop slightly

a1 the instant of contact closure. The

cut-in voltage is the reading which is indicated

immediately before the pointer drops back and

should occur between the limits given in Chapter A

-

General Information. If the cut-in occurs outside

the limits, an adjustment must be made. In this

event reduce engine speed to below cut-in and

proceed as follows.

5.

Remove the control box cover by removing the

securing screws.

6.

Using the special 'Lucas' tool (543-817-42),

turn the cut-out relay adjustment cam a small amount

in the appropriate direction (turning the tool clock-

wise raises the setting and turning the tool

anti-

clockwise lowers the setting).

7.

Repeat Operation

6

until the correct setting is

obtained.

8.

Switch off the engine, fit the original connec-

tions and the cover.

Drop-off voltage-To ad just

1.

Withdraw the cables from the control box

terminal blades

'

B'.

2.

Connect the first grade Zero to 20 Volt moving

coil voltmeter between the control box terminal

marked

'

B'

and earth.

3.

Start the engine and raise the speed to

approximately

3000 [.p.m.

4.

Slowly decelerate and observe the voltmeter

pointer.

5.

Opening of the contacts (indicated by the volt-

meter pointer falling to Zero) should occur between

the limits given in Chapter A

-

General Information.

If the

drop-off voltage occurs outside these limits

an adjustment must be made as follows.

6.

Stop the engine and remove the control box

cover.

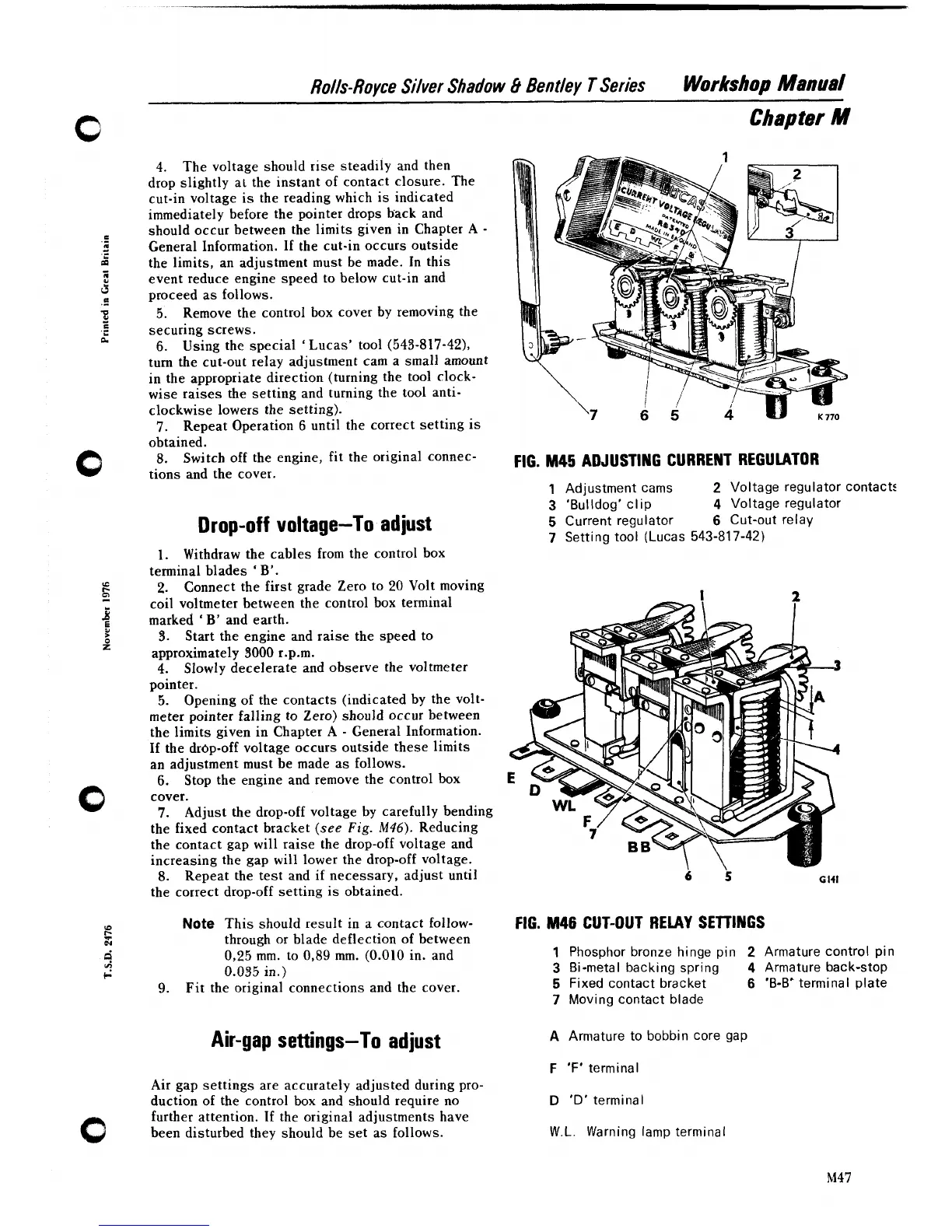

7.

Adjust the drop-off voltage by carefully bending

the fixed contact bracket

(see

Fig.

M46).

Reducing

the contact gap will raise the drop-off voltage and

increasing the gap will lower the drop-off voltage.

8.

Repeat the test and if necessary, adjust until

the correct drop-off setting is obtained.

Note

This should result in a contact follow-

through or blade deflection of between

0,25 mm. to 0,89 mm. (0.010 in. and

0.035

in.)

9.

Fit the original connections and the cover.

Air-gap settings-To adjust

Air gap settings are accurately adjusted during pro-

duction of the control box and should require no

further attention. If the original adjustments have

been disturbed they should be set as follows.

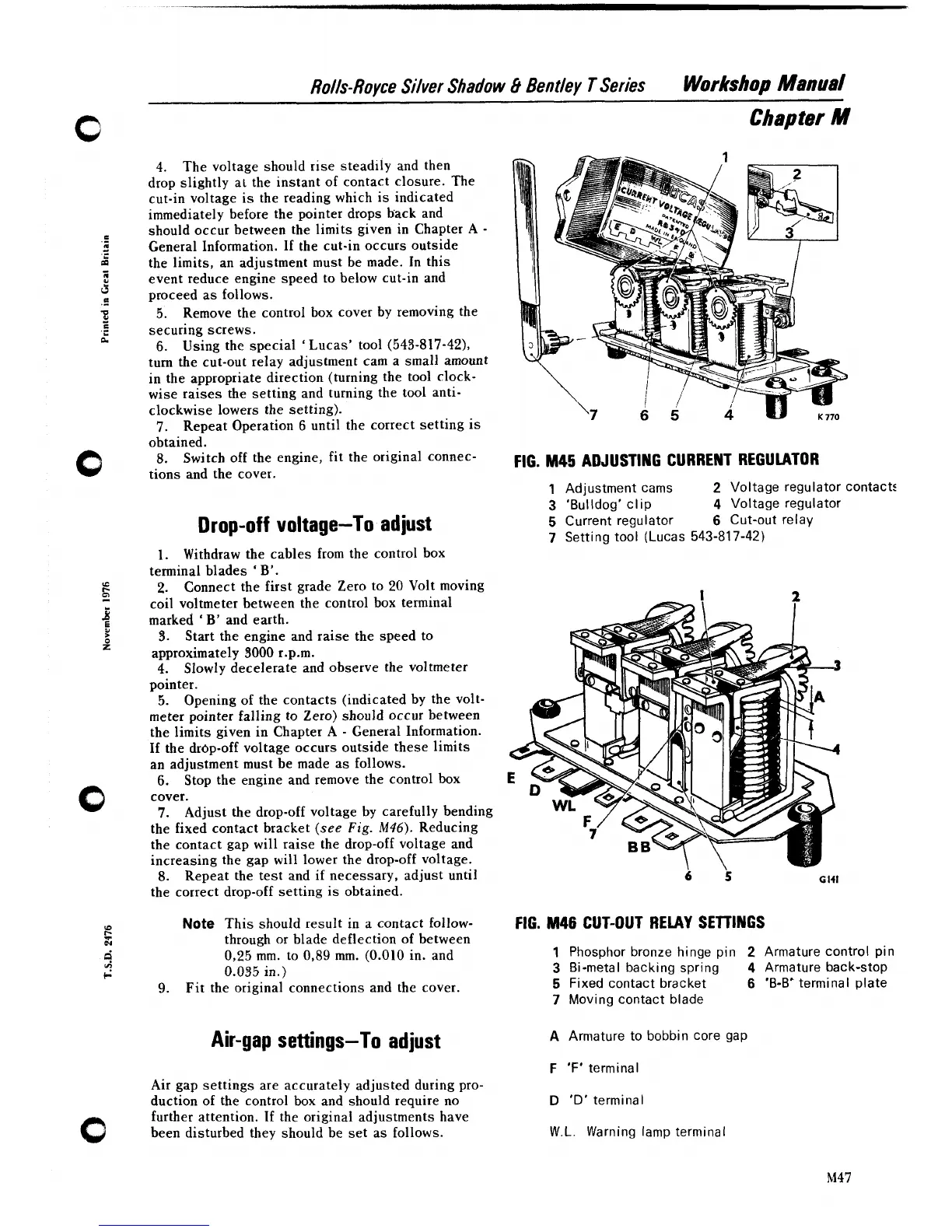

FIG.

M45

ADJUSTING CURRENT REGULATOR

1

Adjustment cams

2

Voltage regulator contacts

3

'Bulldog' clip

4

Voltage regulator

5

Current regulator

6

Cut-out relay

7

Setting tool (Lucas

543-817-42)

FIG.

M46

CUT-OUT RELAY SETTINGS

1

Phosphor bronze hinge pin

2

Armature control pin

3

Bi-metal backing spring

4

Armature back-stop

5

Fixed contact bracket

6

'B-B'

terminal plate

7

Moving contact blade

A

Armature to bobbin core gap

F

'F'

terminal

D

'D' terminal

W.L.

Warning lamp terminal

Loading...

Loading...