Workshop

Manual

Rolls- Royce Silver Shadow

8

Bentle y

T

Series

Chapter

M

3.

Repeat the test, replacing one of the two cables

by the third cable.

Fa~iure of the test lamp to

illuminate on either occasion, means that part of the

stator winding is open-circuit and the stator

must

be

renewed.

4.

Test for defective insulation between the stator

coils and lamination pack with the mains test lamp

(see

Fig.

M30).

5.

Connect the test probes between any one of the

three cable ends and the lamination pack. If the lamp

is illuminated, the stator coils are earthing and the

stator must be renewed.

6.

Before soldering the stator cable ends to the

diode pins, carry out the following test.

Diodes-To test

1.

Each diode can be checked if connected in

series with a 1.5 Watt test bulb across a 12 Volt

(D.C.)

supply. Test again by reversing the

connections

(see

Fig.

M3I).

2.

The bulb should be illuminated and current

should flow in one direction only. Should the bulb

be illuminated in both tests, or not be illuminated in

either test, this indicates a defective diode and the

appropriate heat sink assembly must be renewed.

FIG. M35 MEASURING ROTOR WINDING

3.

The above procedure is adequate for service

purposes but for any accurate measurement of diode

resistance it is necessary for factory equipment to

be available. Since the forward

resis~ance of a diode

varies with the voltage applied, no realistic readings

can be obtained with battery-powered ohmmeters.

However, should a battery-powered ohmmeter be

used

a

serviceable diode will yield 'Infinity' in one

direction and some indefinite, but much lower

reading in the other.

Note

Ohmmeters of the type incorporating a

hand-driven generator must never be used

for checking diodes.

Diode heatsink assembly -To renew

The alternator heat sink assembly comprises two

parts, one of positive polarity and the other negative

(see

Fig.

M33).

The positive portion carries three cathode base

diodes coloured Red and the negative portion carries

three anode base diodes coloured Black.

The diodes cannot be renewed individually, but

for service purposes, they are supplied already

pressed into the appropriate heat sink portion.

When soldering the interconnections,

'

M'

grade

45-55

tin-lead solder should be used.

Great care must be taken to avoid overheating the

diodes or bending the diode pins. The diode pins

should be lightly gripped with a pair of long-nosed

pliers (which act as a thermal shunt). This operation

is shown in Figure

M32;

and the soldering must be

carried out as quickly as possible.

After soldering, the connections must be neatly

arranged around the heat sinks, to ensure adequate

clearance for the rotor and should be tacked down

with

'MMM'

EC 1022 adhesive where indicated in

Figure

M43.

The stator connections must pass through the

appropriate

no~ches at the edge of the heat sink.

Bearings-To renew

Renew any bearings which are worn to such an extent

that they allow excessive side movement of the

rotor shaft.

The needle roller bearing in the slip ring end

bracket cannot be serviced separately. In the un-

likely event of this bearing becoming unserviceable

a complete end bracket assembly must be fitted.

K

699

1.

After withdrawing the rotor shaft from the

drive-end bracket, renew the drive-end ball bearing

race as follows.

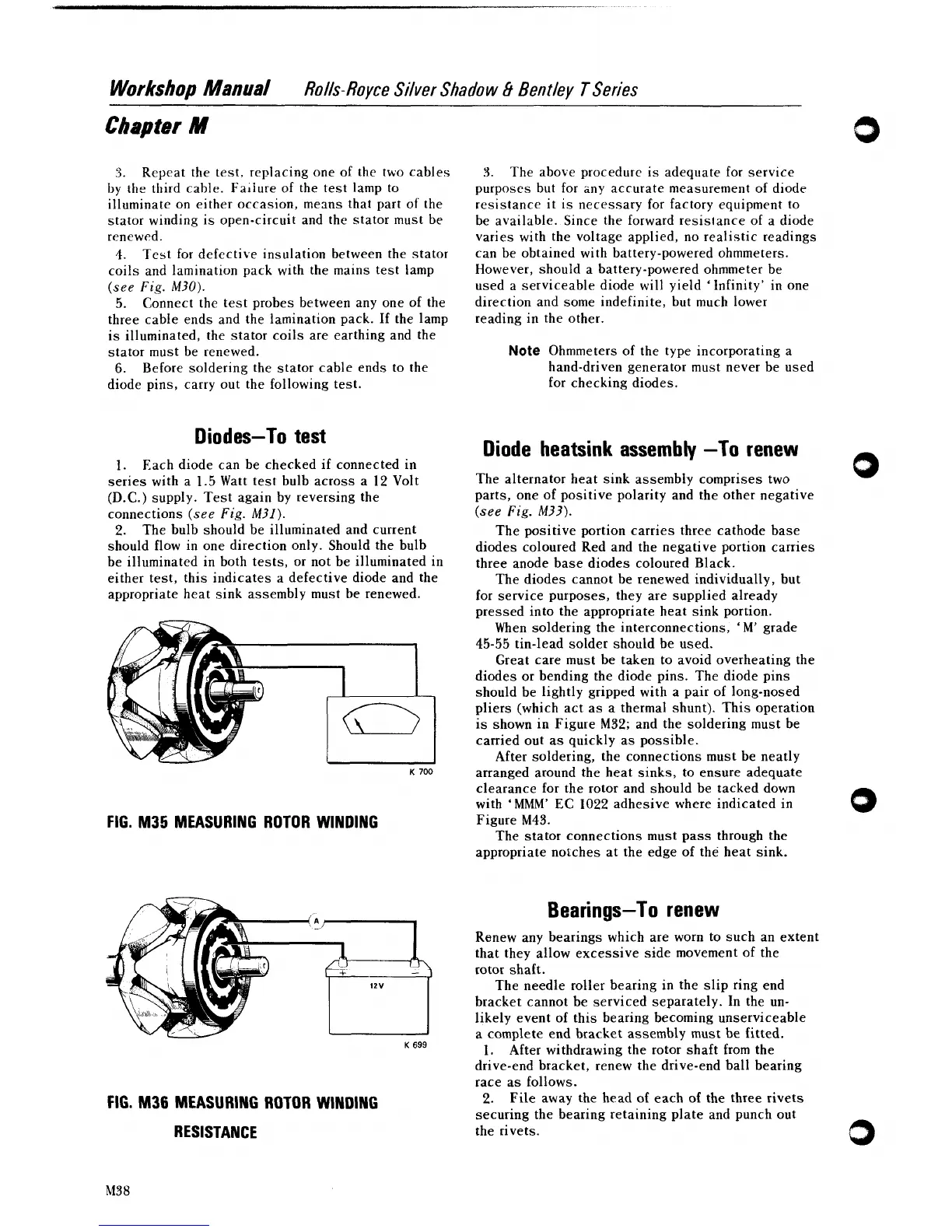

FIG. 111136 MEASURING ROTOR WINDING

2.

File away the head of each of the three rivets

securing the bearing retaining plate and punch out

RESISTANCE

the rivets.

3

Loading...

Loading...