Rolls- Royce Silver Shadow

6

Bentley

T

Series

Workshoa

Manual

Chapter

K

Fuel pump failure

In the United Kingdom all faulty pumps are recondi-

tioned by the manufacturer only; it is therefore

necessary to replace a faulty

unlt with a new or recondi-

tioned unit.

In all other countries, a new or reconditioned pump

should be fitted; if this is not possible, parts can be

obtained and the fault rectified as described in Section

K6-Fault Diagnosis.

All reconditioned pump units and parts are obtain-

able through the Parts Department at Crewe.

Reconditioned fuel pump units

S.U.

reconditioned fuel pump units are of the short

barrel type and incorporate all the latest design

features. The pump mounting studs are

either

of B.S.F.

or U.N.F. thread form, but the correct nuts will be

supplied with each pump. Nuts from other pumps

should not be fitted unless the thread form is known

to be the same as the stud thread on the reconditioned

Pump.

Neither inlet or outlet unions are supplied with

reconditioned pumps. These parts should be removed

from the faulty pump unit before its return to

Rolls-

Royce Limited.

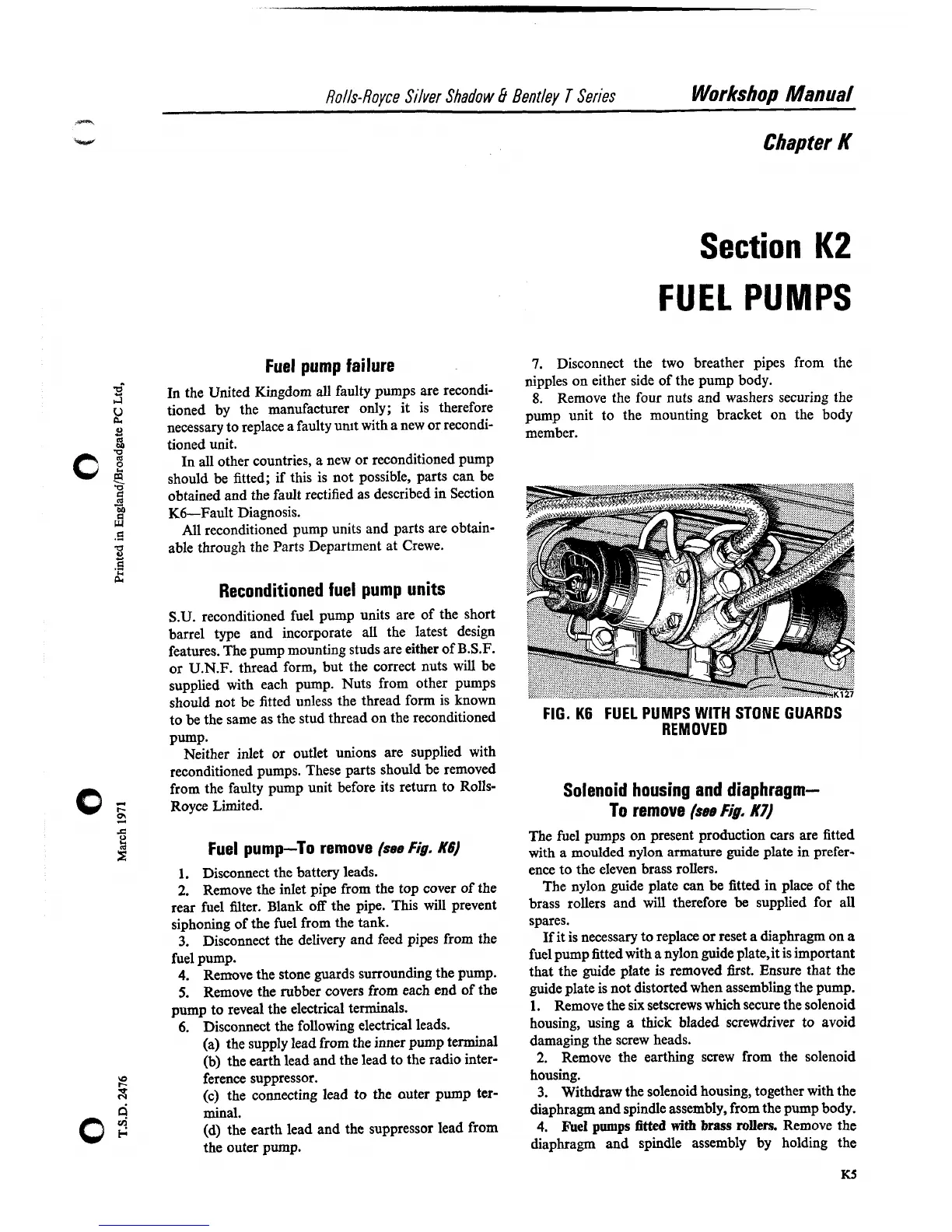

Fuel pump-To remove

(see

Fig.

K6)

1.

Disconnect the battery leads.

2.

Remove the inlet pipe from the top cover of the

rear fuel filter. Blank off the pipe. This will prevent

siphoning of the fuel from the tank.

3.

Disconnect the delivery and feed pipes from the

fuel pump.

4. Remove the stone guards surrounding the pump.

5.

Remove the rubber covers from each end of the

pump to reveal the electrical terminals.

6.

Disconnect the following electrical leads.

(a) the supply lead from the inner pump terminal

(b) the earth lead and the lead to the radio inter-

ference suppressor.

(c) the connecting lead to the auter pump ter-

minal.

(d) the earth lead and the suppressor lead from

the outer pump.

Section

K2

FUEL

PUMPS

7.

Disconnect the two breather pipes from the

nipples on either side of the pump body.

8.

Remove the four nuts and washers securing the

pump unit to the mounting bracket on the body

member.

FIG.

K6

FUEL PUMPS

WITH STONE

GUARDS

REMOVED

Solenoid housing

and

diaphragm-

To

remove

(see

Fig.

K7)

The fuel pumps on present production cars are fitted

with a moulded nylon armature guide plate in prefer-

ence to the eleven brass rollers.

The nylon guide plate can be fitted

in

place of the

brass rollers and will therefore

be

supplied for all

spares.

If it is necessary to replace or reset a diaphragm on

a

fuel pump fitted with a nylon guide plate3 is important

that the guide plate is removed first. Ensure that the

guide plate is not distorted when assembling the pump.

1.

Remove the six setscrews which secure the solenoid

housing, using

a

thick bladed screwdriver to avoid

damaging the screw heads.

2.

Remove the earthing screw from the solenoid

housing.

3.

Withdraw the solenoid housing, together with the

diaphragm and spindle assembly, from the pump body.

4.

Fuel

pumps

fitted

with

brass rollers.

Remove the

diaphragm and spindle assembly by holding the

Loading...

Loading...