workshop

Manual

Rolls Royce Silver Shadow

&

Bentley

T

Ser~es

Chapter

K

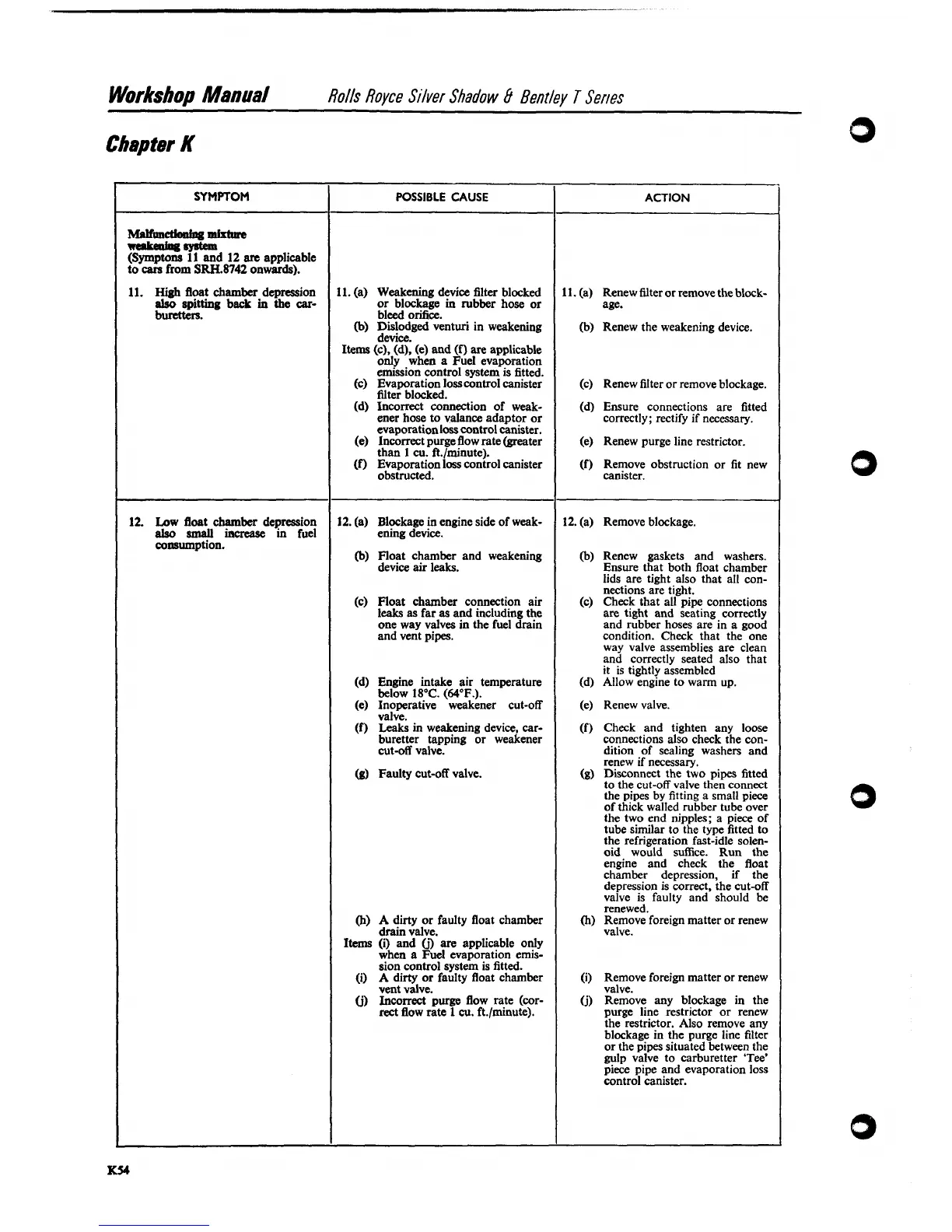

SYMPTOM

--mirQre

--

(Symptom

11

and

12

arc

applicable

to

cars

from

SRH.8742

onwards).

11.

High

float

chamber

depression

also

spitting

back

in the

car-

buretters.

12.

Low

float

+her

depression

also

small

~ncrease

m fuel

consumption.

POSSIBLE CAUSE

11.

(a)

Weakening

device filter blocked

or blockage in rubber hose or

bleed orifice.

(b)

Dislodged venturi in weakening

device.

Items

(c), (d), (e) and

(f)

are applicable

only when a Fuel evaporation

emission control system is fitted.

(c) Evaporation losscontrol canister

Nter blocked.

(d) Incorrect connection of weak-

ener hose to valance adaptor or

evaporation loss control canister.

(e) Incorrect purge flow rate (greater

than

1

cu. ft./minute).

(f)

Evaporationloss control canister

obstructed.

12. (a) Blockage in engine side of weak-

ening device.

(b)

Float chamber and weakening

device air leaks.

(c) Float chamber connection air

leaks

as

far

as

and including the

one way valves in the fuel drain

and vent pipes.

(d) Engine intake air temperature

below

18°C.

(64°F.).

(e) Inoperative weakener cut-off

valve.

(f)

Leaks in weakening device, car-

buretter tapping or weakener

cut-off valve.

(g)

Faulty cut-off valve.

(h)

A dirty or faulty float chamber

drain valve.

Items

(i) and

(j)

are applicable o@y

when

a

Fuel

evaporation

emls-

sion control system is fitted.

(i)

A

dirty or faulty float chamber

vent valve.

(j)

Incorrect purge flow rate (cor-

rect

flow rate

1

cu. ft./minute).

ACTION

11.

(a) Renew filter or remove the block-

age.

(b)

Renew the weakening device.

(c) Renew filter or remove blockage.

(d) Ensure connections are fitted

correctly; rectify if necessary.

(e) Renew purge line restrictor.

(f) Remove obstruction or fit new

canister.

12. (a) Remove blockage.

(b)

Renew gaskets and washers.

Ensure that both float chamber

lids are tight also that all con-

nections are tight.

(c) Check that all pipe connections

are tight and seating correctly

and rubber hoses are in a good

condition. Check that the one

way valve assemblies are clean

and correctly seated also that

it is tightly assembled

(d) Allow engine to warm up.

(e) Renew valve.

(f) Check and tighten any loose

connections also check the con-

dition of sealing washers and

renew if necessary.

(g) Disconnect the two pipes fitted

to the cut-off valve then connect

the pipes by fitting a small piece

of thick walled rubber tube over

the two end nipples; a piece of

tube similar to the type fitted to

the refrigeration fast-idle solen-

oid would suffice. Run the

engine and check the float

chamber depression, if the

depression is correct, the cut-off

valve is faulty and should be

renewed.

(h)

Remove foreign matter or renew

valve.

(i)

Remove foreign matter or renew

valve.

(j)

Remove any blockage in the

purge line restrictor or renew

the restrictor. Also remove any

blockage in the purge line filter

or the pipes situated between the

gulp valve to carburetter 'Tee'

piece pipe and evaporation loss

control canister.

Loading...

Loading...