S0602170K

Page 103

Axle (ZF AP 420R)

3. Screw in adjusting nut (opposite the crown

wheel side) until the differential bearing

has no endplay.

4. Now, tighten adjusting nut further for 2

notches to obtained the required bearing

preload of the differential bearing 3 - 4 Nm

(26.5 - 35.4 in lb).

5. Check backlash again and correct if

necessary.

NOTE:

At this step make several

revolutions of the differential.

Determine yoke width.

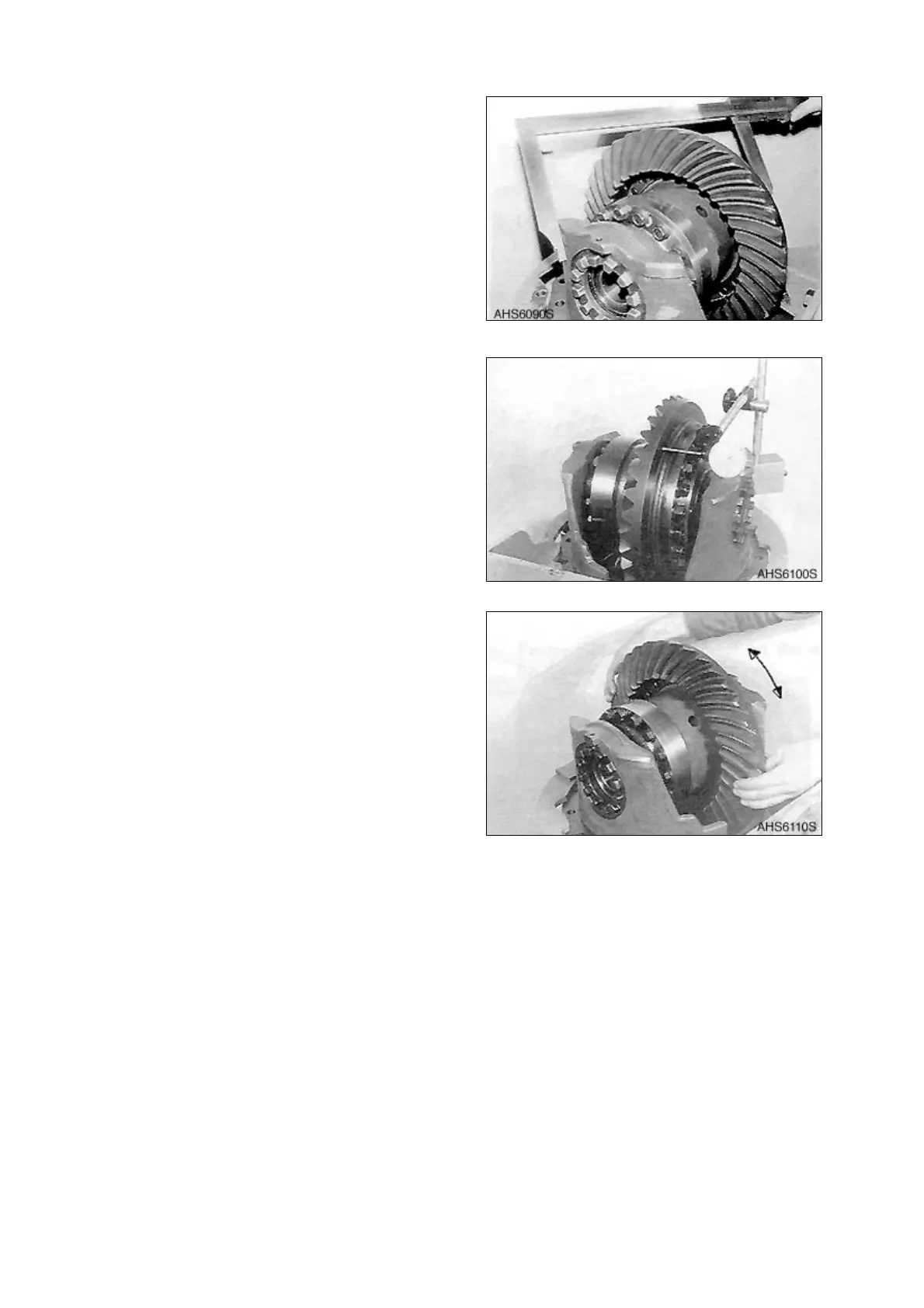

6. Attach dial indicator on the plane face/

crown wheel, make at least one revolution

of the crown wheel and record the run-out.

NOTE:

Admitted run-out max. 0.08 mm

(0.0031 in).

NOTE:

See “Special Tools” on page 15.

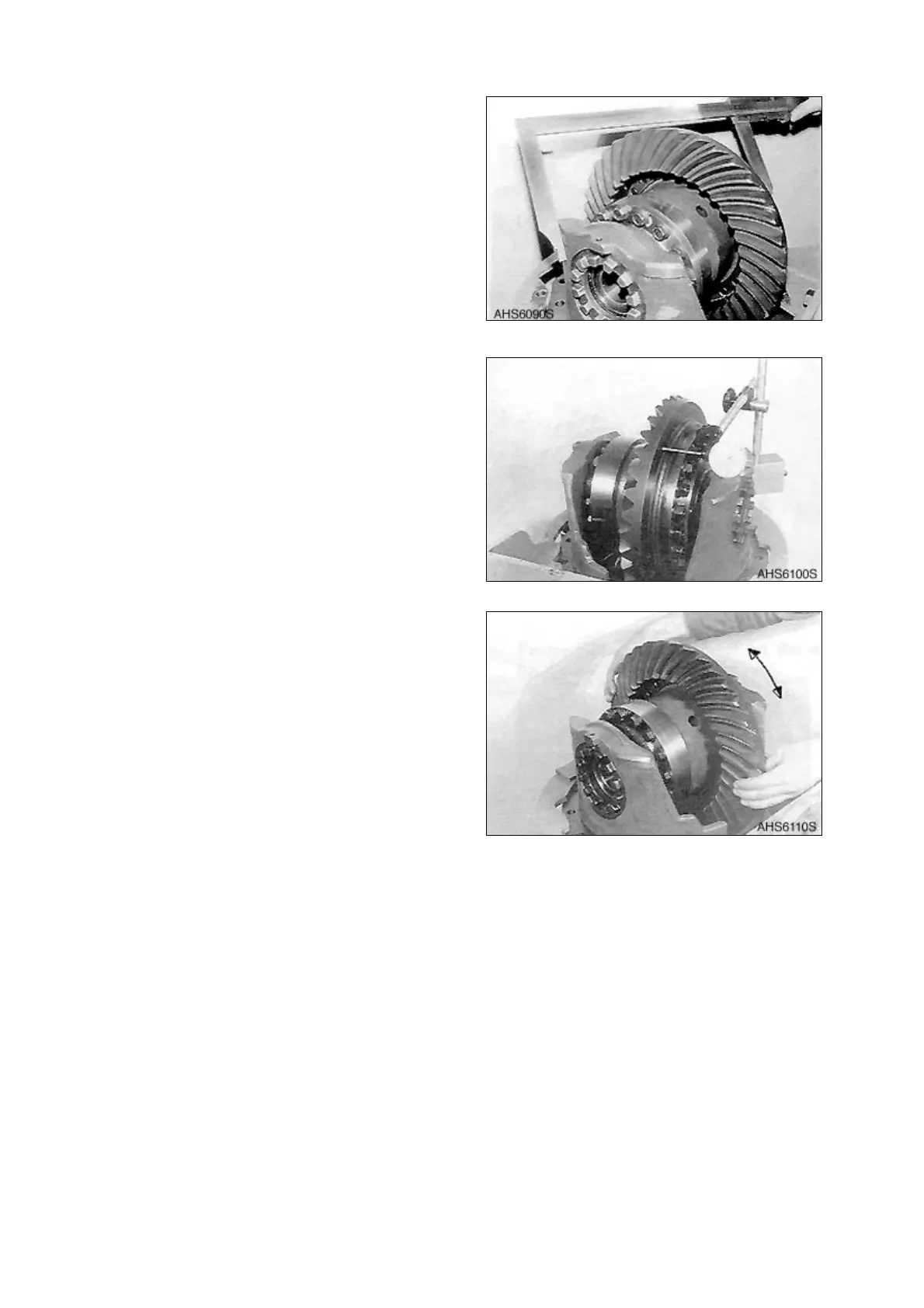

7. Check contact pattern on the crown wheel

A. Cover some tooth flanks of the crown

wheel with gear marking compound.

B. Roll the clown wheel over the drive

pinion back and forth.

C. Take the contact pattern and

compare it with “Examples of Gear-

tooth-contact Patterns for the

Gleason Gear-tooth System” on

page 11.

D. In case of a greater contact pattern

deviation, a spacing error has been

made during the reassembly of the

drive pinion, which must be

corrected.

Figure 235

Figure 236

Figure 237

Loading...

Loading...