S0705010

Page 17

Cylinders

Return to Master Table of Contents

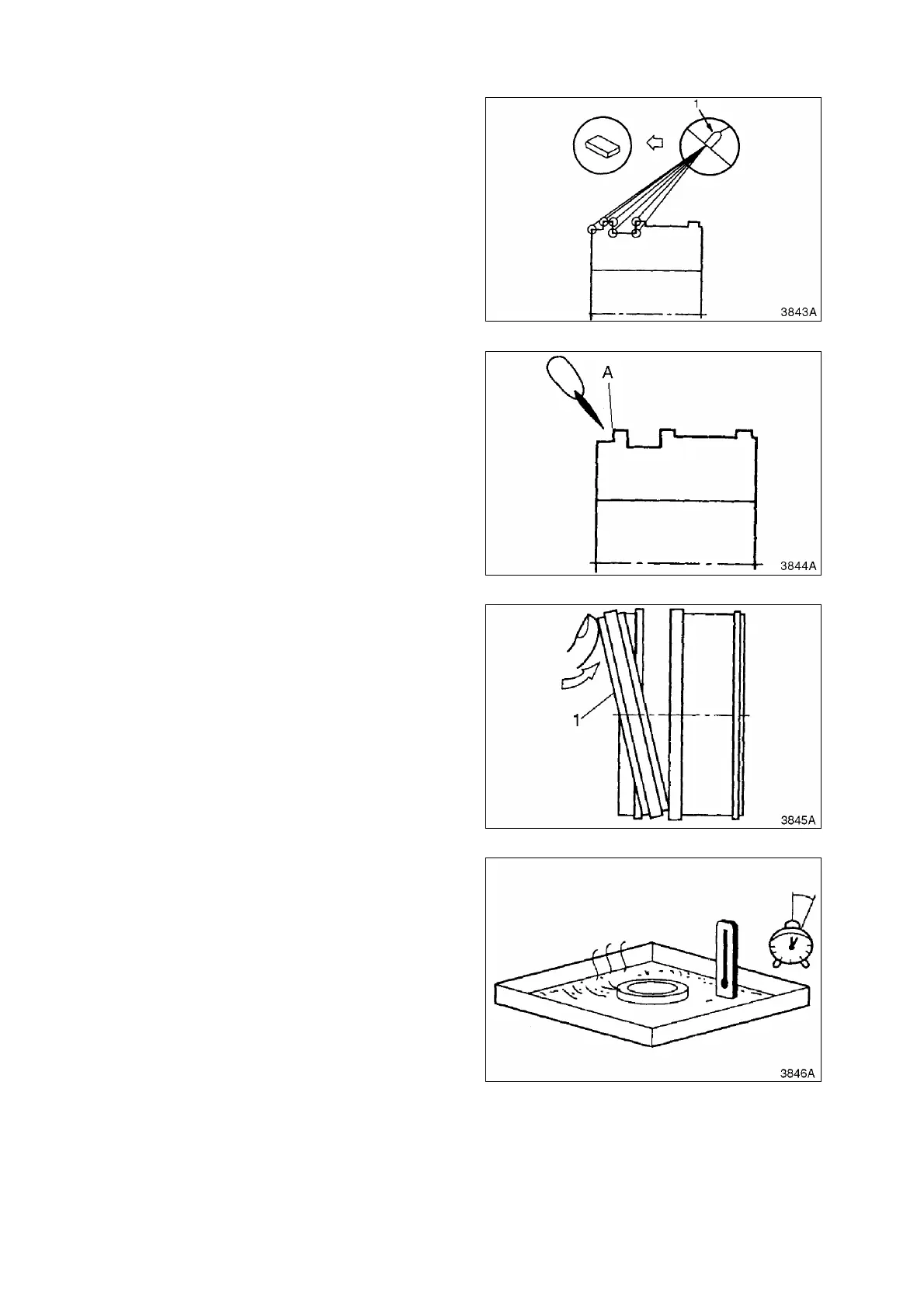

10. On piston, check corners of grooves that

piston rings will be mounted in. See Figure

24. If any burrs, roughness, or sharp

edges (1) are present, use an oil stone to

smooth roughened areas and dull sharp

edges.

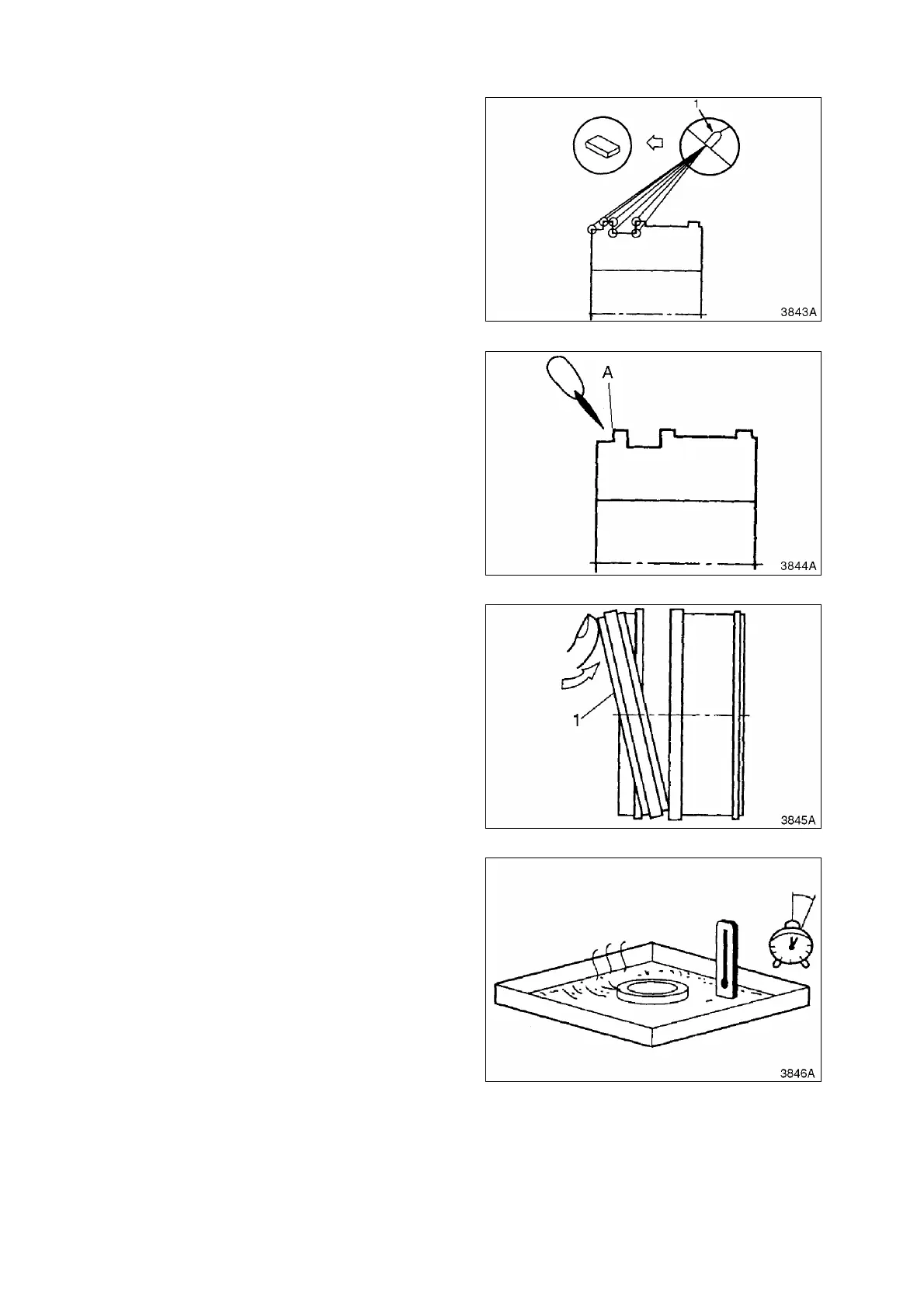

11. Apply grease or hydraulic oil to corner of

piston at position A. See Figure 25.

12. Insert one end of backup ring into its

groove. See Figure 26. Use your hand to

slide other end of ring into groove.

13. Use warm water to expand slipper seal.

See Figure 27. This will make seal easier

to install. Set slipper seal in 60 -100

degree C (140 - 212 degree F) water for 5

minutes or longer.

Figure 24

Figure 25

Figure 26

Figure 27

Loading...

Loading...