·230·

Operating manual

CNC 8055

CNC 8055i

13.

DIAGNOSIS

·T· MODEL

SOFT: V02.2X

Adjustments

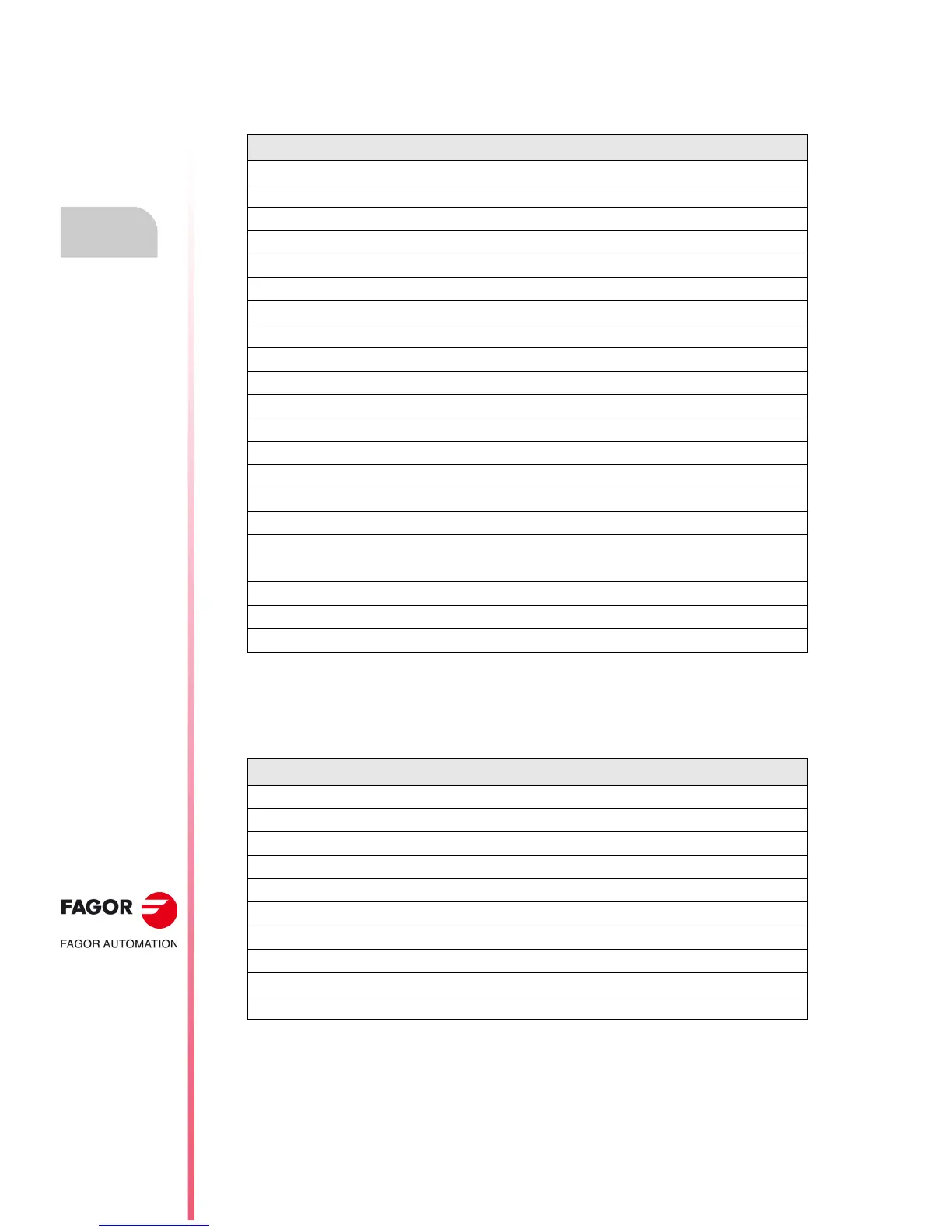

CNC variables that may be assigned to a channel

Indicate the desired variable.

Example: ANAI1 FREAL FLWEX.

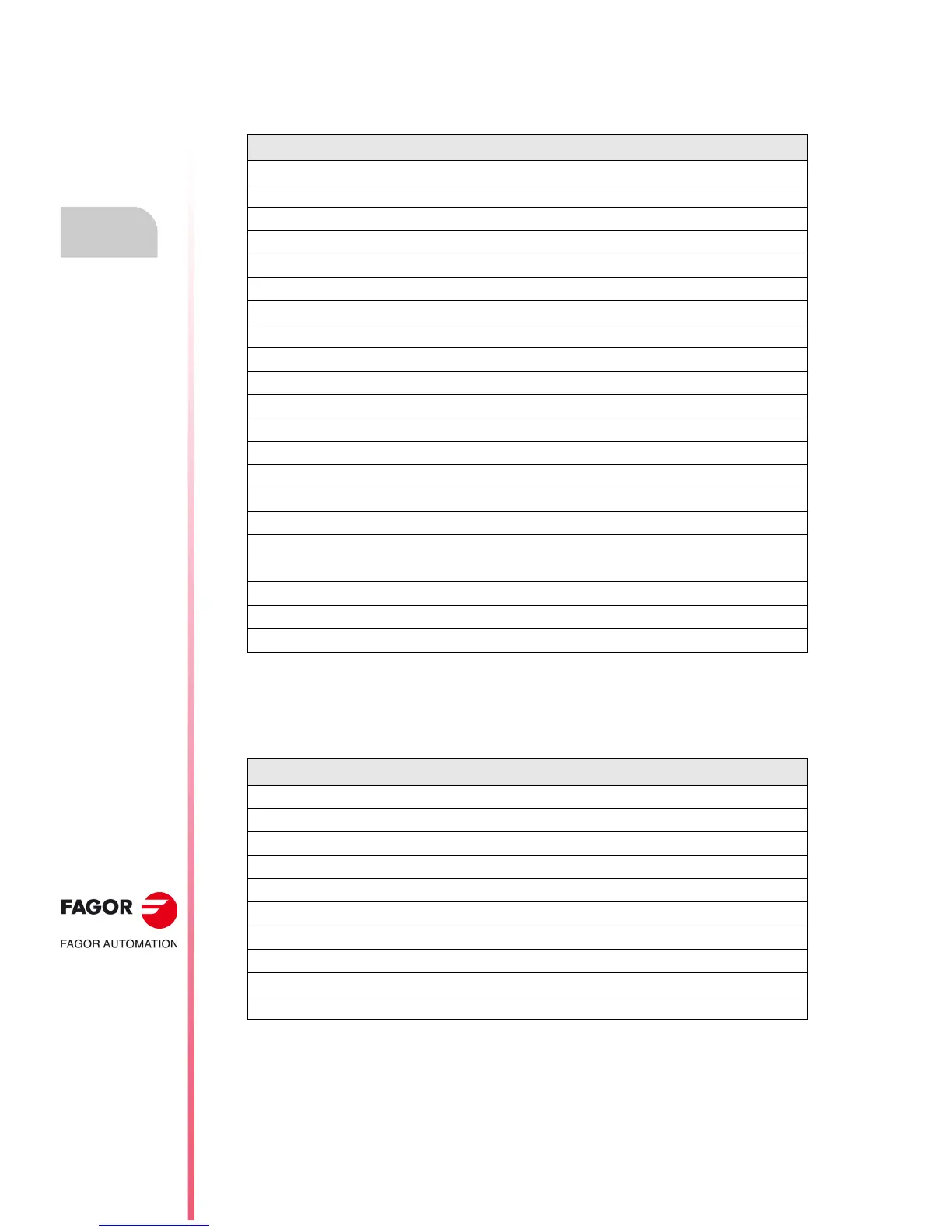

Fagor Sercos or CAN drive variables that may be assigned to a channel

Indicate the desired axis or spindle and variable, separated by a period. The auxiliary spindle is

identified with the prefix "AS".

Example: X.CV3 Y.SV1 S1.SV2 AS.SV1

Variable Description

ANAI(1-8) Voltage of input 1-8.

ANAO(1-8) Voltage to apply to output 1-8.

FREAL Actual (real) CNC feedrate.

FREAL(X-C) Actual (real) X-C axis feedrate

FTEO(X-C) Theoretical X-C axis feedrate

FLWE(X-C) X-C axis following error.

ASIN(X-C) "A" signal of the CNC's sinusoidal feedback for the X-C axis.

BSIN(X-C) "B" signal of the CNC's sinusoidal feedback for the X-C axis.

DRPO(X-C) Position indicated by the Sercos drive of the X-C axis.

SREAL Real spindle speed.

FTEOS Theoretical spindle speed.

FLWES Spindle following error.

ASINS "A" signal of the CNC's sinusoidal feedback for the spindle.

BSINS "B" signal of the CNC's sinusoidal feedback for the spindle.

DRPOS Position indicated by the Sercos drive of the spindle.

SSREAL Real speed of the second spindle.

SFTEOS Theoretical speed of the second spindle.

SFLWES Following error (lag) of the second spindle.

SASINS "A" signal of the CNC sinusoidal feedback for the second spindle.

SBSINS "B" signal of the CNC sinusoidal feedback for the second spindle.

SDRPOS Position indicated by the Sercos drive of the second spindle.

Variable Description

CV3 CurrentFeedback

SV1 VelocityCommand

SV2 VelocityFeedback

SV7 VelocityCommandFinal

TV1 TorqueCommand

TV4 VelocityIntegralAction

RV1 FeedbackSine

RV2 FeedbackCosine

RV51 Feedback2Sine

RV52 Feedback2Cosine

Loading...

Loading...