·232·

Operating manual

CNC 8055

CNC 8055i

13.

DIAGNOSIS

·T· MODEL

SOFT: V02.2X

Adjustments

• Superimposed channels

If this option is not selected, all the signals appear separated. The screen is divided into as many

horizontal strips as active and visible channels have been defined. The signals are shown with

their own graphic zero and ordered from top to bottom in the defined order (CH1, CH2, CH3,

CH4).

If this option is selected all the signals appear superimposed, with a single graphic zero located

at the center of the screen.

During the analysis of the signals, it is possible to change modes by pressing the [M] key.

Machine parameter setting

The parameters defining page shows the definition code on the left column, the parameter name

on the center column and the maximum and minimum values on the right column.

• To add a parameter to the list, select the row for the parameter, enter the definition code and

press [ENTER]. If the parameter is valid, the rest of the fields are updated and if not, it issues

a warning.

• To replace a parameter from the list, select the parameter to be replaced, enter the definition

code of the new parameter and press [ENTER]. If the previous content has been deleted and

no code is entered, the line appears empty.

• The [Add a parameter to the list] softkey enters a new empty line above the currently selected line.

• The [Eliminate parameter] softkey eliminates the currently selected line and shifts all the ones

below upwards.

The parameters are always shown in the same place where they were defined and the empty rows

appear blank.

When a parameter is changed, the CNC machine parameter table and the drive's work parameters

are updated. The [Save parameters] softkey is also activated. It is recommended to save the

parameter tables that have been changed, those of the CNC into the hard disk (KeyCF) and those

of the drive in its FLASH. If only the CNC parameters have been changed, the drive tables remain

unchanged and vice versa.

Once the values saved are the same as the ones edited last, the softkey disappears until a new

modification is made.

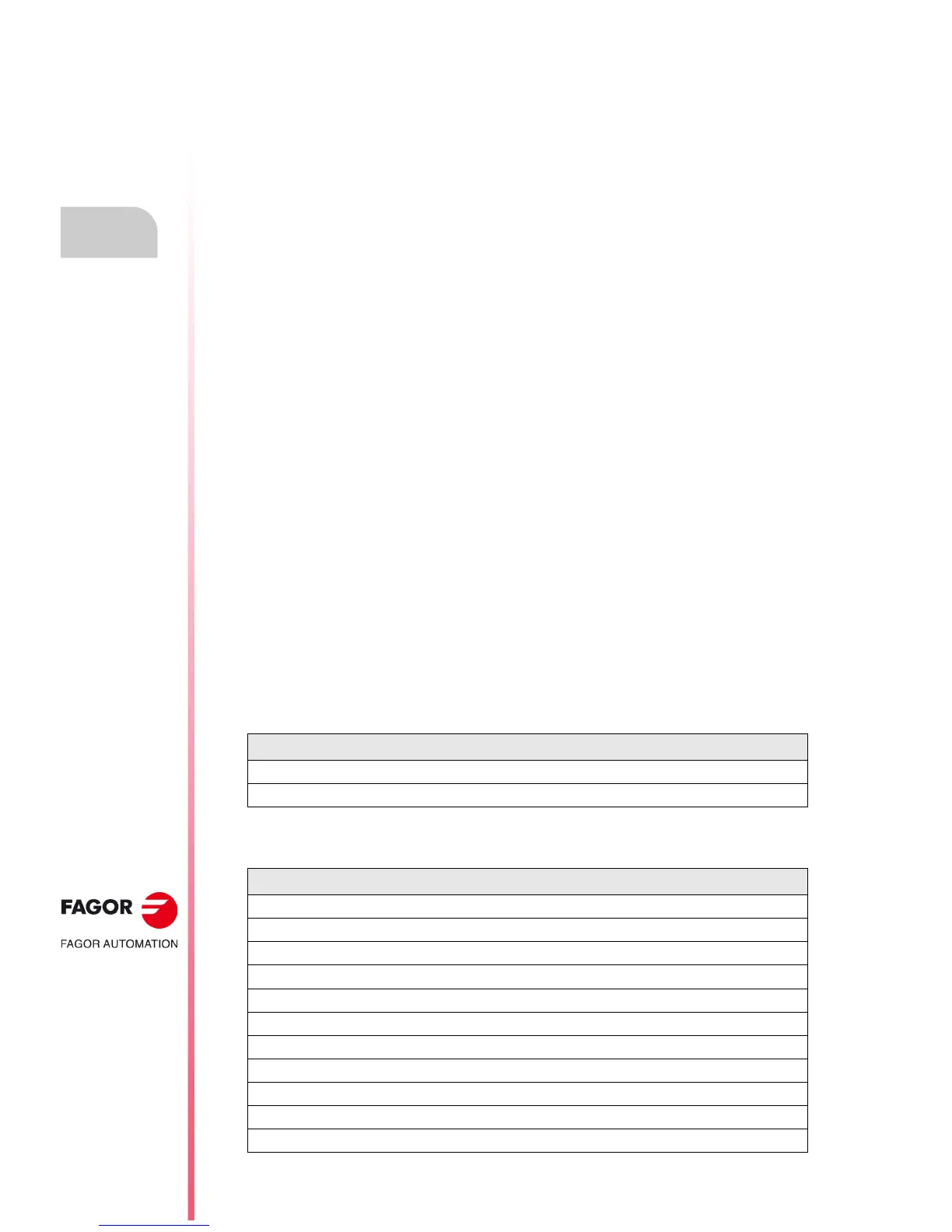

CNC machine parameters that may be modified

General machine parameters: Enter the indicator of the general parameter and the parameter

number separated by a point.

Example: G.P161

Machine parameters of an axis: Indicate the axis and the parameter number separated by a period.

Example: X.P18 Z.P23

Parameter Number Update

TLOOK P161 Beginning of program execution

CODISET P147 Immediate

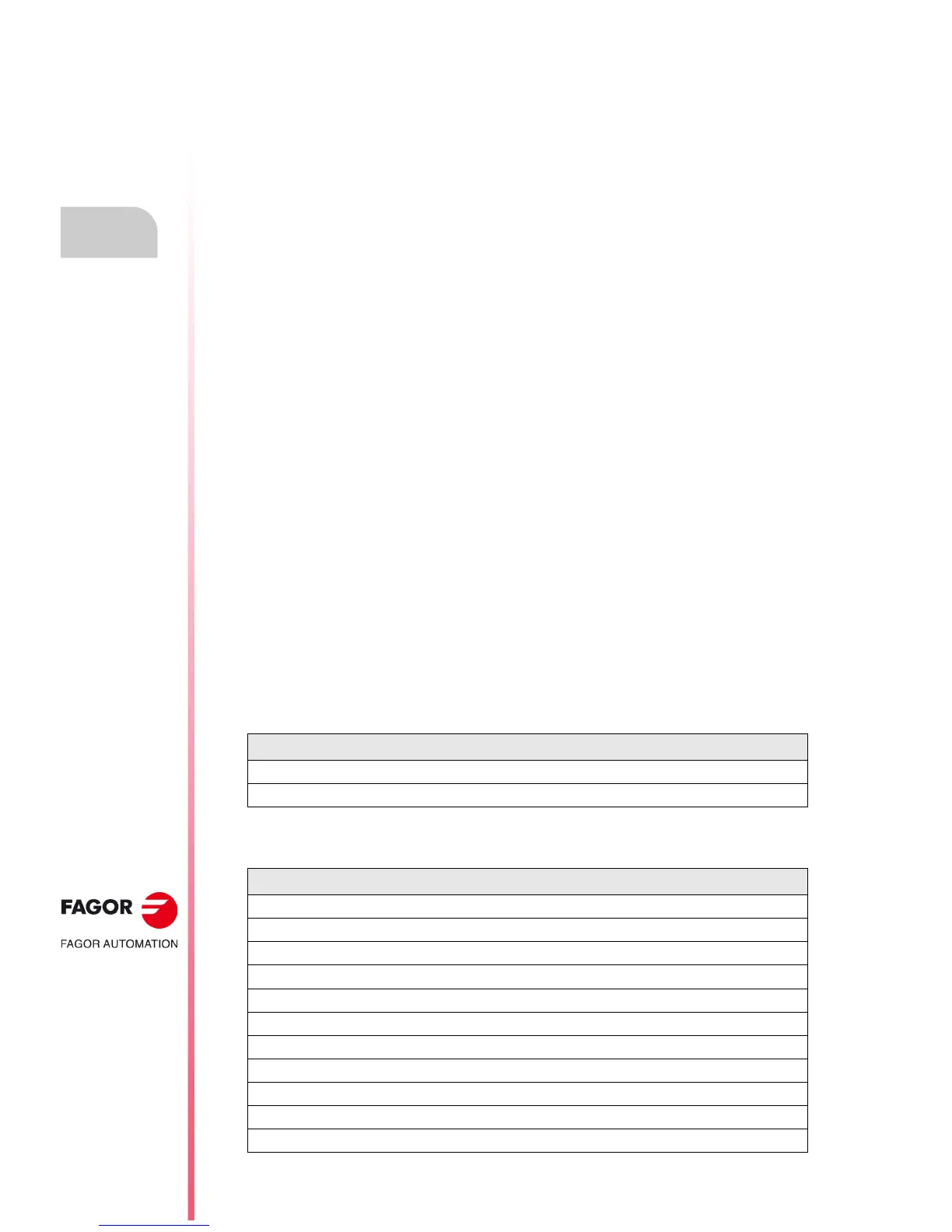

Parameter Number Update

BACKLASH P14 Immediate

ACCTIME P18 Beginning of the next block

INPOSW P19 Immediate

MAXFLWE1 P21 Immediate

MAXFLWE2 P22 Immediate

PROGAIN P23 Immediate

DERGAIN P24 Immediate

FFGAIN P25 Immediate

MINANOUT P27 Immediate

SERVOFF P28 Immediate

BAKANOUT P29 Immediate

Loading...

Loading...