Cleaning and Disinfection

• Avoid exposure to highly alkaline conditions (pH > 11), as this can damage

products (for example, aluminum parts).

• Never use conductive solutions or solutions that contain wax or wax compounds

to clean the equipment.

• Do not immerse the device in any liquid as this may corrode metal contacts and

affect signal quality.

• Do not drip or expose the writer assembly to any liquids.

• Do not allow fluid to pool around connection pins. If this happens, blot dry with a

soft, lint-free cloth.

• Avoid contact with open vents, plugs, or connectors during the cleaning and

disinfecting procedures.

• Never autoclave or steam-clean the device.

• Do not use until thoroughly dry.

• Do not use any of below materials to clean the device, because their use may

damage equipment surfaces.

• Organic solvents

• Abrasive cleaners or solvents of any kind

• Acetone

• Ketone

• Betadine

• Sodium salts

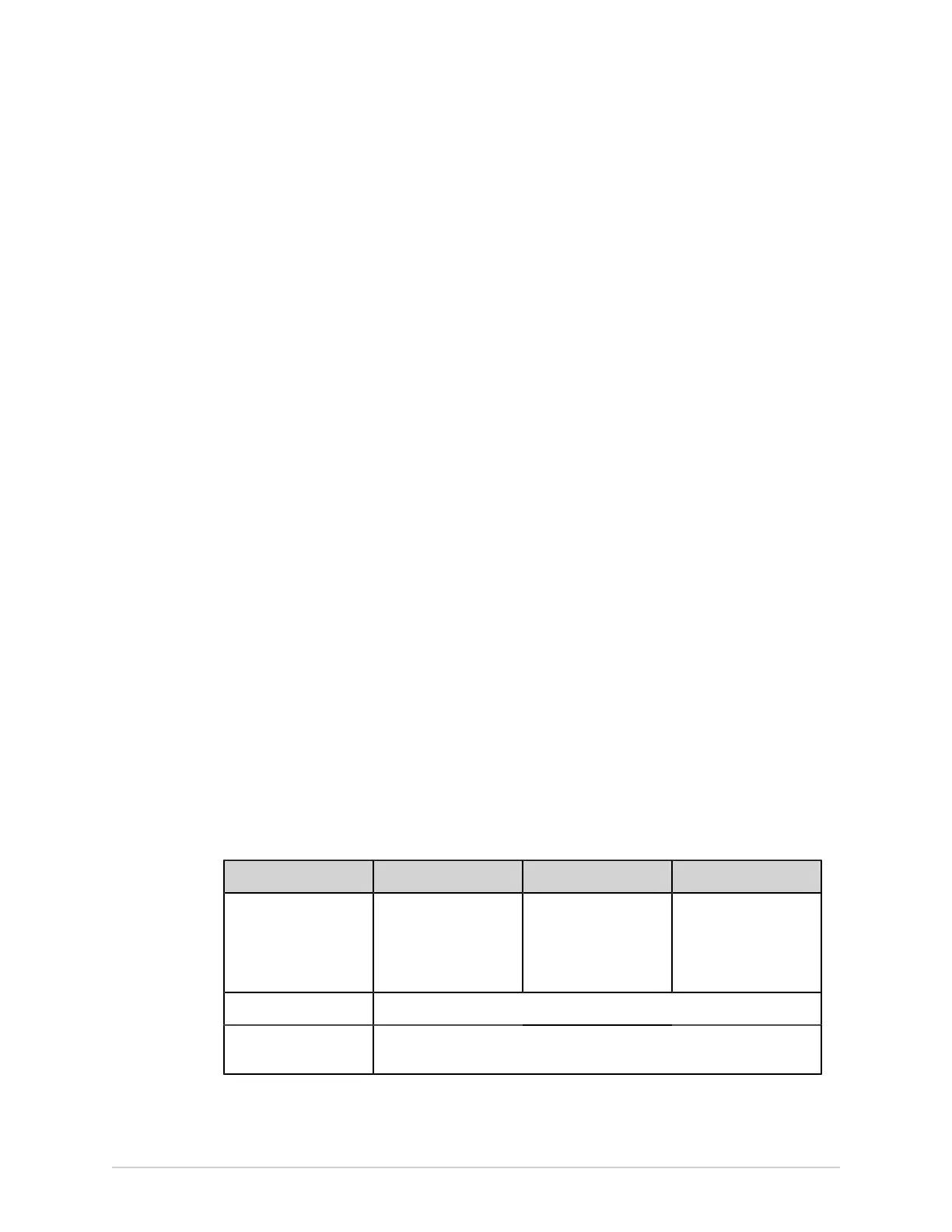

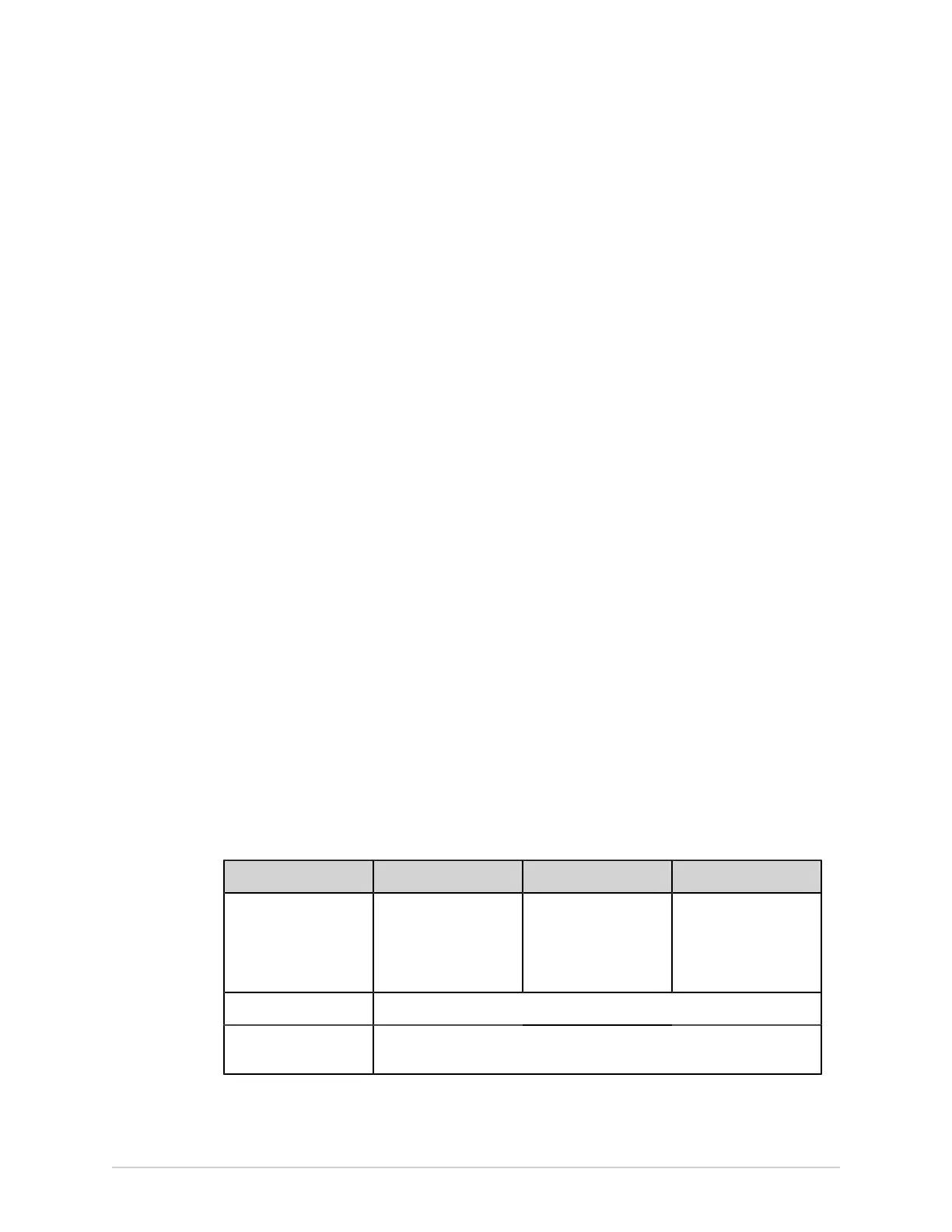

Visual Inspection, Cleaning and Disinfection Frequency

The table indicates the frequency of visual inspection, cleaning, and disinfection

procedures.

Component Visual Inspection Cleaning Disinfection

Device and Trolley

NOTE:

Trolley is an

optional purchase.

Daily, preferably before

the equipment’s first

use each day

Monthly, or more

frequently, as needed

Follow the same

frequency as cleaning.

Disinfection must

be performed after

cleaning.

Leadwires Refer to the supplier's instructions for leadwire cleaning and disinfection.

Reusable electrodes Refer to the supplier's instructions for reusable electrode cleaning,

disinfection and sterilization.

270 MAC

™

5 A4/MAC

™

5 A5/MAC

™

5 Lite 5864335-001-1

Loading...

Loading...