225

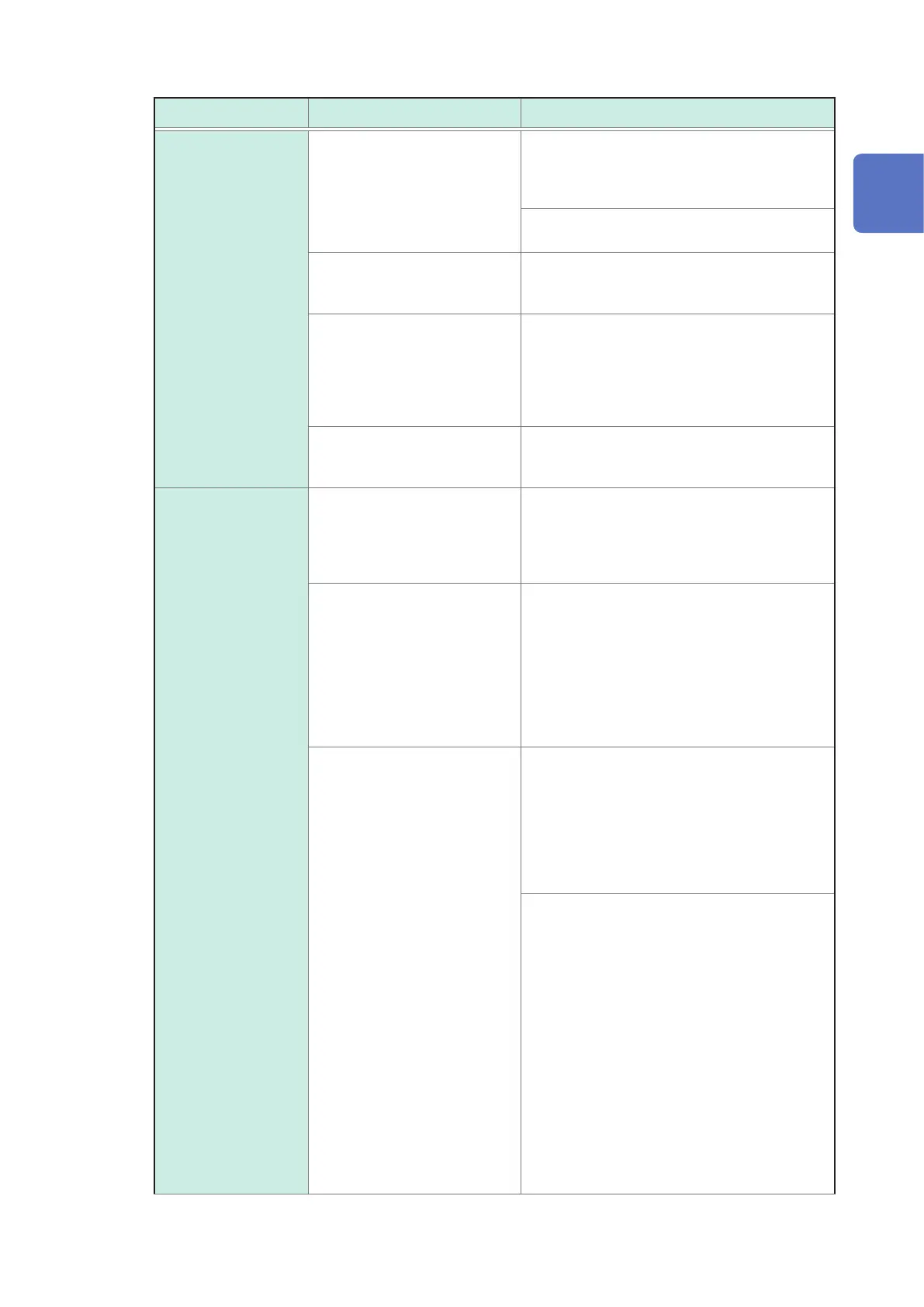

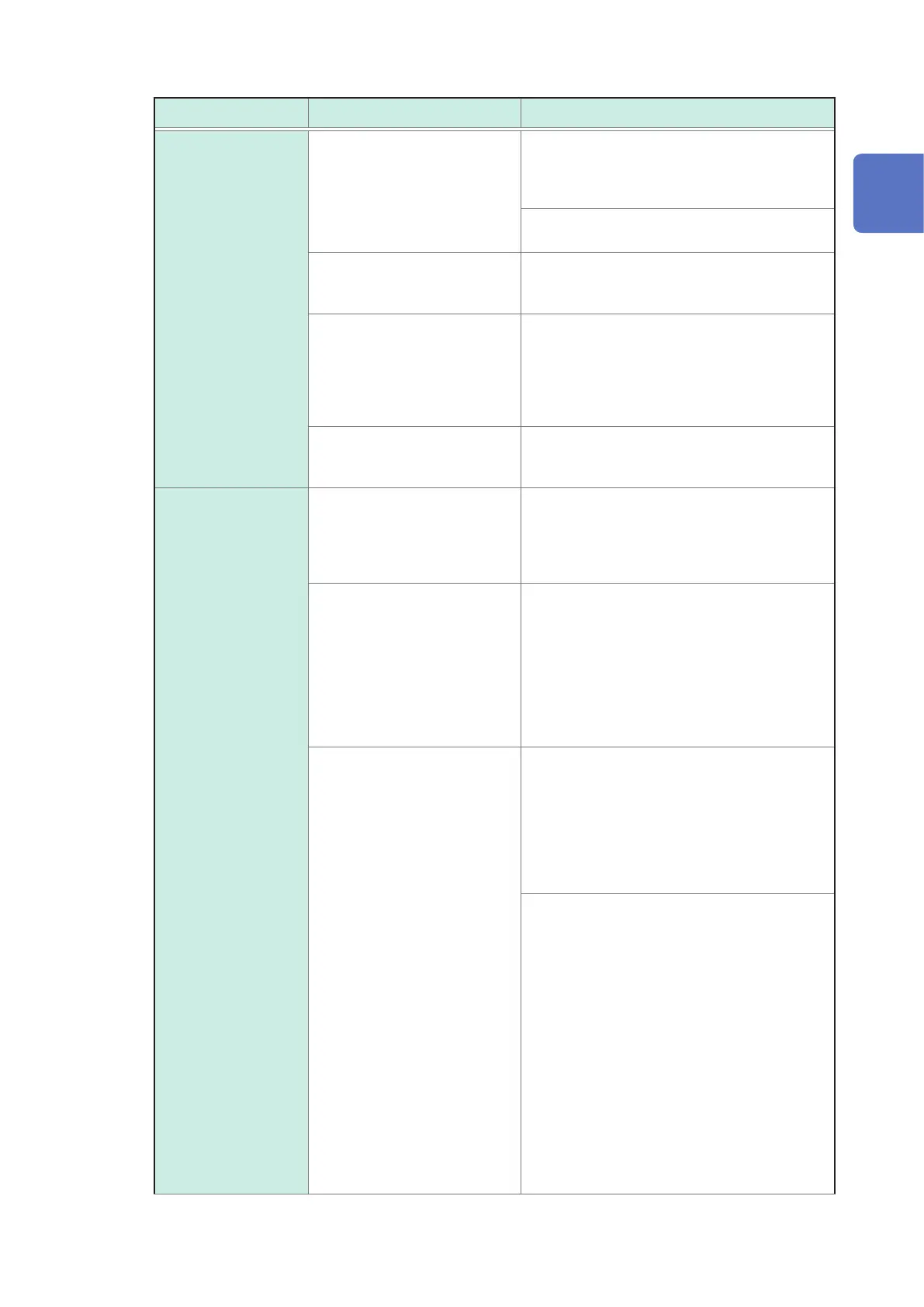

Troubleshooting

Symptom Cause Remedy and Reference

The measurement

values are exhibiting

excessive variation.

Measurement is being per-

formed using a 2-terminal con-

nection.

• Two-terminal connections are susceptible

to the inuence of contact resistance. When

possible, use a 4-terminal connection to the

sample’s electrodes to perform measurement.

• Add a wait time to allow contact to stabilize

before measurement.

Open and short correction has

not been performed.

Perform open and short correction properly.

See"5.2 Open Correction" (p. 99) and "5.3

Short Correction" (p. 105).

Rdc measurement is being

performed before the voltage

stabilizes.

Include an adequate DC delay and adjustment

delay.

See "DC delay (setting the DC measurement

delay time) (DC)" (p. 61) and "Adjustment de-

lay (setting the offset measurement delay time)

(DC)" (p. 62).

Multiple IM3536 instruments are

being used in close proximity to

each other.

Separate instruments and measurement cables

before use.

You are unable to

perform measurement

properly.

An error is being displayed. Check the item indicated by the error display,

address the cause, and then perform measure-

ment.

See "11.3 Error Massage and Error Display"

(p. 230).

An OVERFLOW or UNDER-

FLOW message is being dis-

played.

(Measured value greater than

upper limit/less than lower limit

error)

See "11.3 Error Massage and

Error Display" (p. 230).

• If the range is not appropriate:

Change to an appropriate range or perform

measurement using auto ranging. It is neces-

sary to set both the AC measurement and DC

measurement ranges.

See "Measurement range (AC/DC)" (p. 45).

• If there is a break or short in the wiring:

Check the wiring and perform measurement

with the correct wiring connections.

An error such as an NC A L

or NC B L message is being

displayed. (Contact error)

See "11.3 Error Massage and

Error Display" (p. 230).

• The sample has not been properly secured

in the xture. Verify that the sample has been

properly secured.

Refer to the instruction manual of the xture.

• Check the measurement cable and xture for

broken wires or poor contact.

See "2.4 Connecting the Measurement Cables,

Probes, or Fixture" (p. 35).

If you are using the instrument in a high-noise

environment, consider taking the following mea-

sures:

• Use guarding.

See "Appx. 2 Measurement of High Impedance

Components" (p. Appx.3).

• Implement anti-external noise measures.

See"Appx. 4 Countermeasures Against Incor-

poration of External Noise" (p. Appx.5).

• Separate the sample, measurement cables,

and instrument from the source of the noise

(motor, inverter, electromagnetic switch, power

line, equipment generating sparks, etc.) or

perform the measurement in a separate room.

• Plug the instrument into a grounded outlet.

• Use a separate power supply from the device

that is generating the noise.

Maintenance and Service

11

Loading...

Loading...