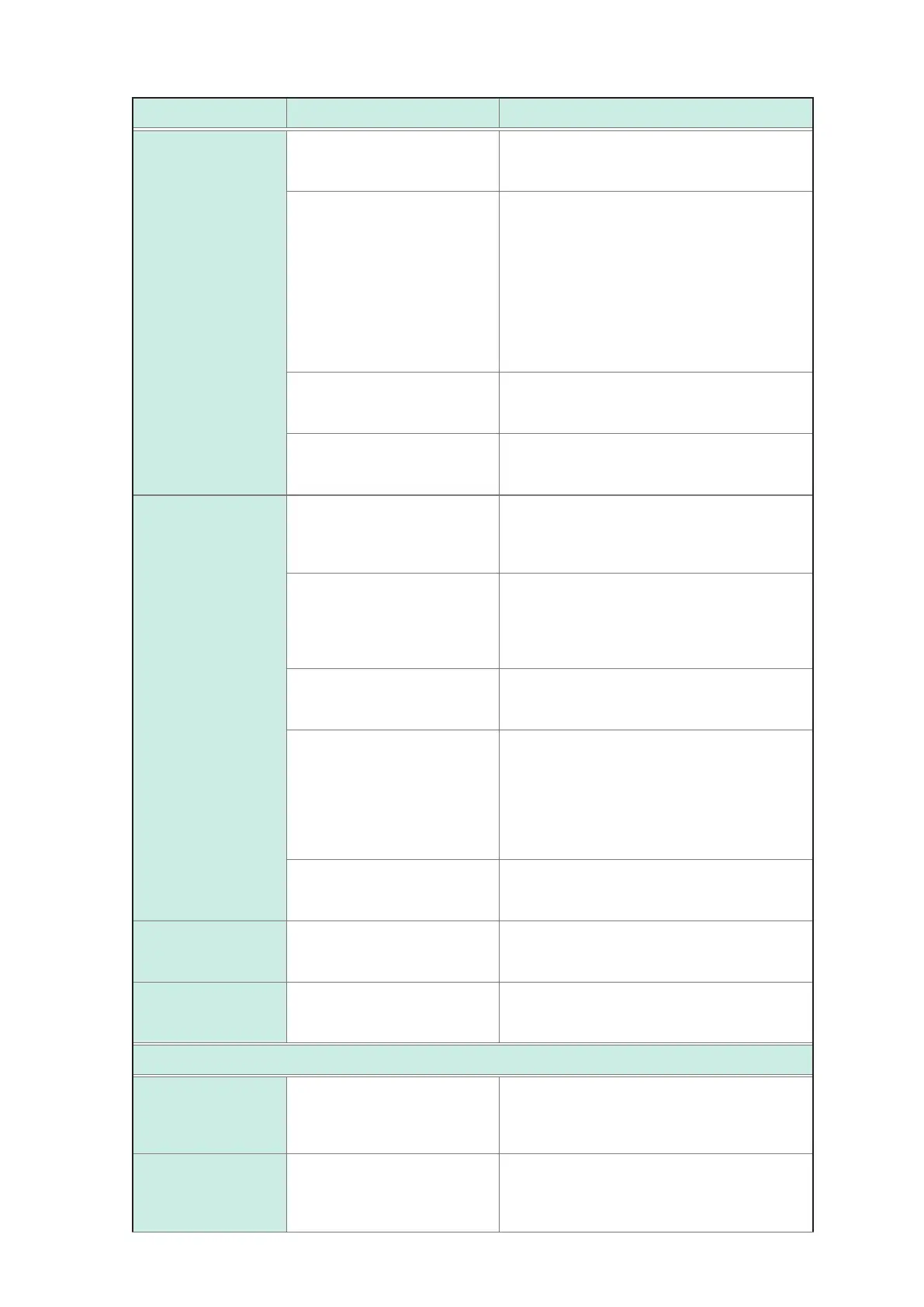

226

Troubleshooting

Symptom Cause Remedy and Reference

You are unable to

perform measurement

properly.

An element with its own voltage,

for example a battery, is being

measured.

If there is a high DC voltage, you may damage

the instrument. Avoid measuring the sample.

An element on a circuit board is

being measured.

• You can measure an element on a printed cir-

cuit board if the target element is isolated from

external connections. However, if the target

element is connected to other components or

external circuitry, you will not be able to obtain

a proper measurement.

• You may be unable to measure components

in circuits that are generating a voltage or to

which a voltage is being applied, for example

because they are energized.

A high-impedance element is

being measured in a noisy envi-

ronment.

Use guarding.

See "Appx. 2 Measurement of High Impedance

Components" (p. Appx.3).

The DC bias function is being

used for a sample other than a

capacitor.

Set the DC bias function OFF.

See "DC bias (superimposing a DC voltage on

the measurement signal)(AC)" (p. 59).

The measurement val-

ues differ when a stan-

dard resistor, standard

capacitor, or other

known test sample is

measured.

The known sample measure-

ment conditions and the instru-

ment’s measurement conditions

do not match.

Make sure the measurement conditions match.

The open or short correction

method is wrong.

Perform open and short correction properly. To

perform short correction for the 9140-10, use a

short bar without directly shorting the tip.

See "5.2 Open Correction" (p. 99), and "5.3

Short Correction" (p. 105).

Load correction has been en-

abled.

Set the load correction off.

See "5.6 Load Correction (Correcting Values to

Match Reference Values)" (p. 112).

The delay time from connection

of the sample to measurement

is not long enough.

Ensure there is an appropriate trigger delay and

trigger synchronous output wait time.

See "Trigger (perform measurements with user-

dened timing) (Common)" (p. 62) and "Trig-

ger synchronous output (Applying the signal to

the sample during measurement only) (Com-

mon)" (p. 64).

The DC bias function is being

used while measuring an ele-

ment other than a capacitor.

Set the DC bias function off.

See "DC bias (superimposing a DC voltage on

the measurement signal)(AC)" (p. 59).

AUTO ranging is un-

able to determine a

range.

A high-impedance element is

being measured in a noisy envi-

ronment.

Use guarding.

See "Appx. 2 Measurement of High Impedance

Components" (p. Appx.3).

AUTO ranging is un-

able to determine a

range.

The DC bias function is being

used while measuring an ele-

ment other than a capacitor.

Set the DC bias function off.

Set "DC bias (superimposing a DC voltage on

the measurement signal)(AC)" (p. 59).

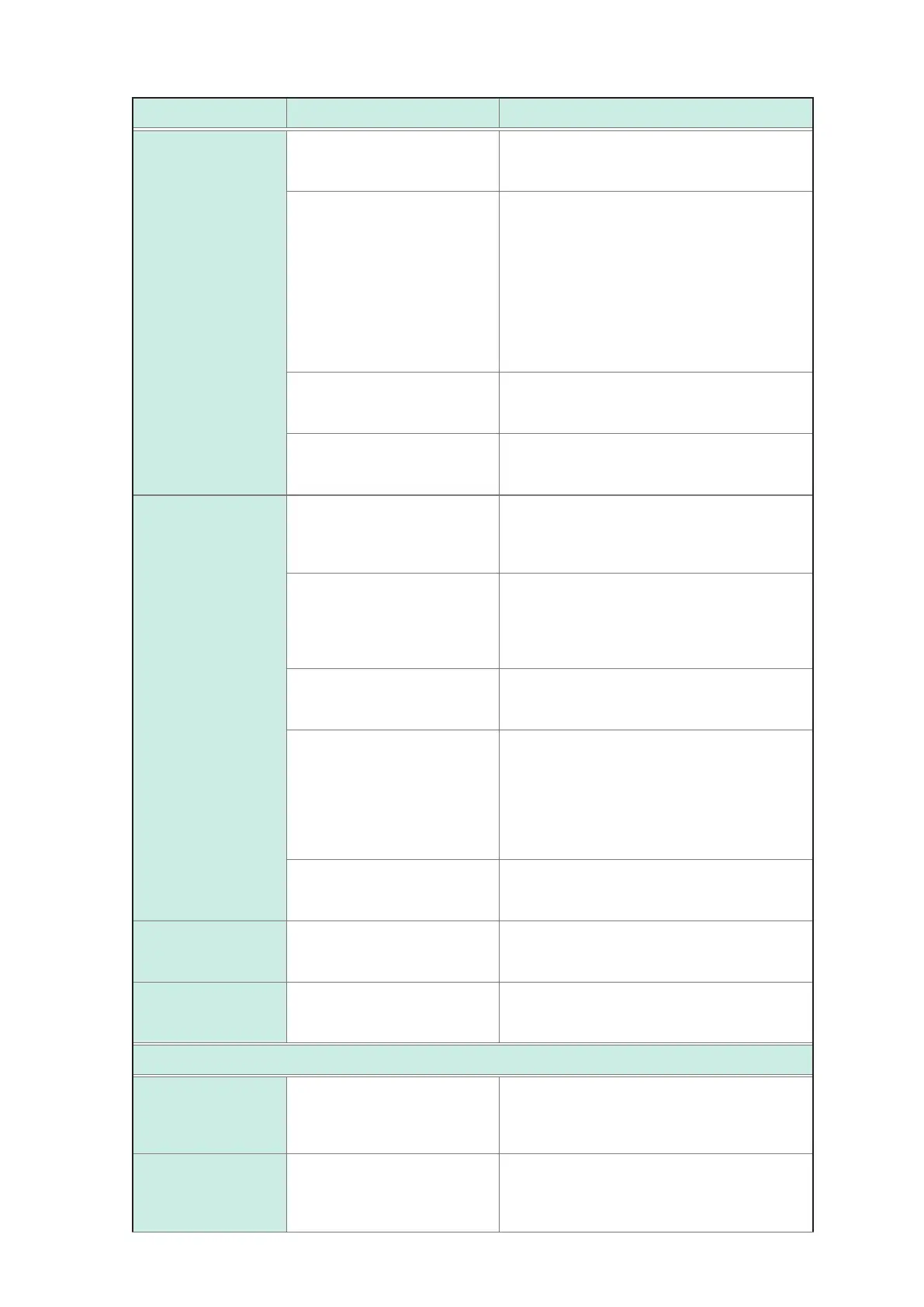

Errors

A contact error is gen-

erated even though

the connections are

correct.

The DC bias function is being

used while measuring an ele-

ment other than a capacitor.

Set the DC bias function off.

See "DC bias (superimposing a DC voltage on

the measurement signal)(AC)" (p. 59).

Open correction or

short correction re-

sulted in an error.

The wrong connection method

is being used for open correc-

tion or short correction.

Perform open correction or short correction with

the proper wiring.

See "5.2 Open Correction" (p. 99) and "5.3

Short Correction" (p. 105).

Loading...

Loading...