Trainee Guide TR-L2-M2000

Level 2 Maintenance Training – M2000 Dispensing Systems 4-2-28 P/N 73-0018-00 (Revision B)

Information Sheet 4-8-5

DV-6000 Troubleshooting (Continued)

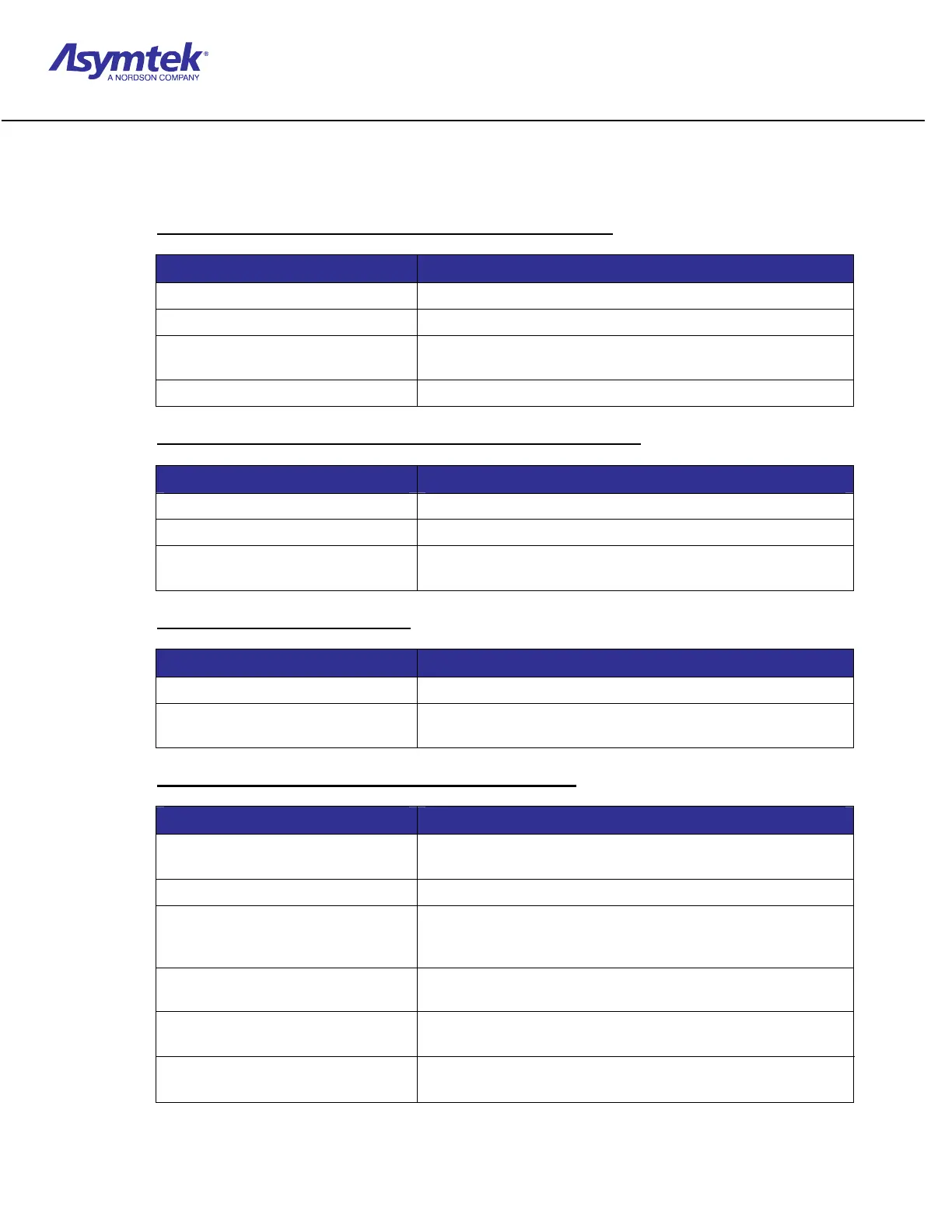

D. Material Drips For A Short Time And Eventually Stops

Possible Cause Recovery

1. Air in Fluid 1. Purge thoroughly or use degassed material.

2. Valve set too high 2. Lower valve pressure.

3. Syringe plunger is incorrect

type

3. Change plunger to orange no-draft stopper or yellow

stopper.

4. Fluid is slightly compressible 4. Add a short valve pullback (0.05 to 0.1 seconds).

E. Fluid Leaking From Overflow Port On Side Of Valve Body

Possible Cause Recovery

1. Cup seal is worn out 1. Replace cup seal.

2. Valve pressure set too high 2. Lower valve pressure.

3. Feedscrew has worn at the

shoulder

3. Replace seal or send valve back for refurbishment.

F. Dispensed Fluid Is Discolored

Possible Cause Recovery

1. Abrasive fluid is wearing seal 1. Change to UHMW seal.

2. Abrasive fluid is wearing the

feedscrew

2. None.

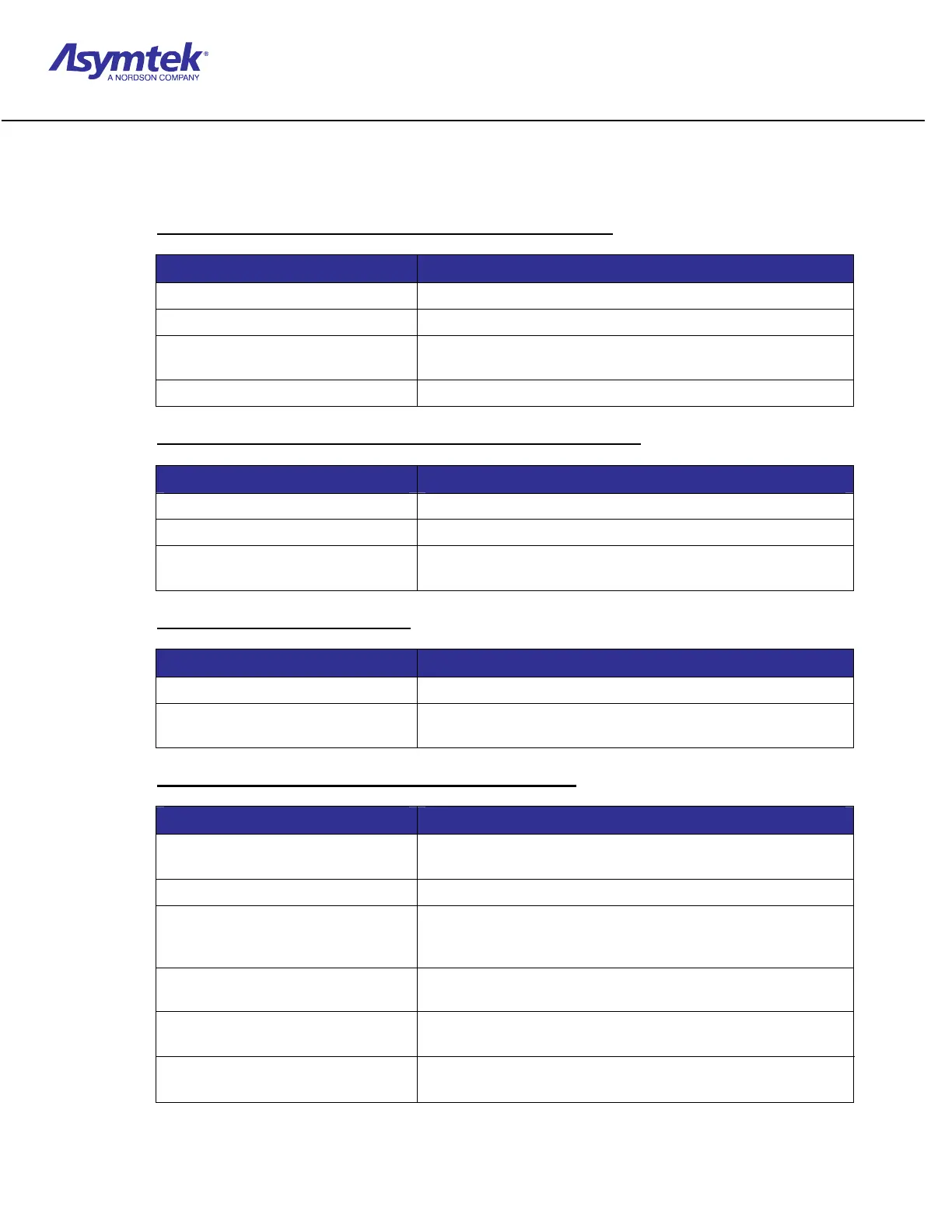

G. Valve And/Or Needle Clogging With Solder Paste

Possible Cause Recovery

1. Solder paste is not a

dispensable grade

1. Select a dispensable grade.

2. Needle size is too small 2. Use a larger needle.

3. Valve not primed with

conditioning fluid prior to

dispensing

3. Prime valve.

4. Solder paste packaged in 30

cc syringes

4. Use 10 cc or smaller syringes to reduce agitation time.

5. Dispensing tip not tightened

properly.

5. Use torque wrench to tighten tip.

6. Tip too close to substrate or

touching substrate

6. Raise dispensing height.

Loading...

Loading...