Trainee Guide TR-L2-M2000

Level 2 Maintenance Training – M2000 Dispensing Systems 4-2-33 P/N 73-0018-00 (Revision B)

Information Sheet 4-8-10

DJ-2000 Troubleshooting (Continued)

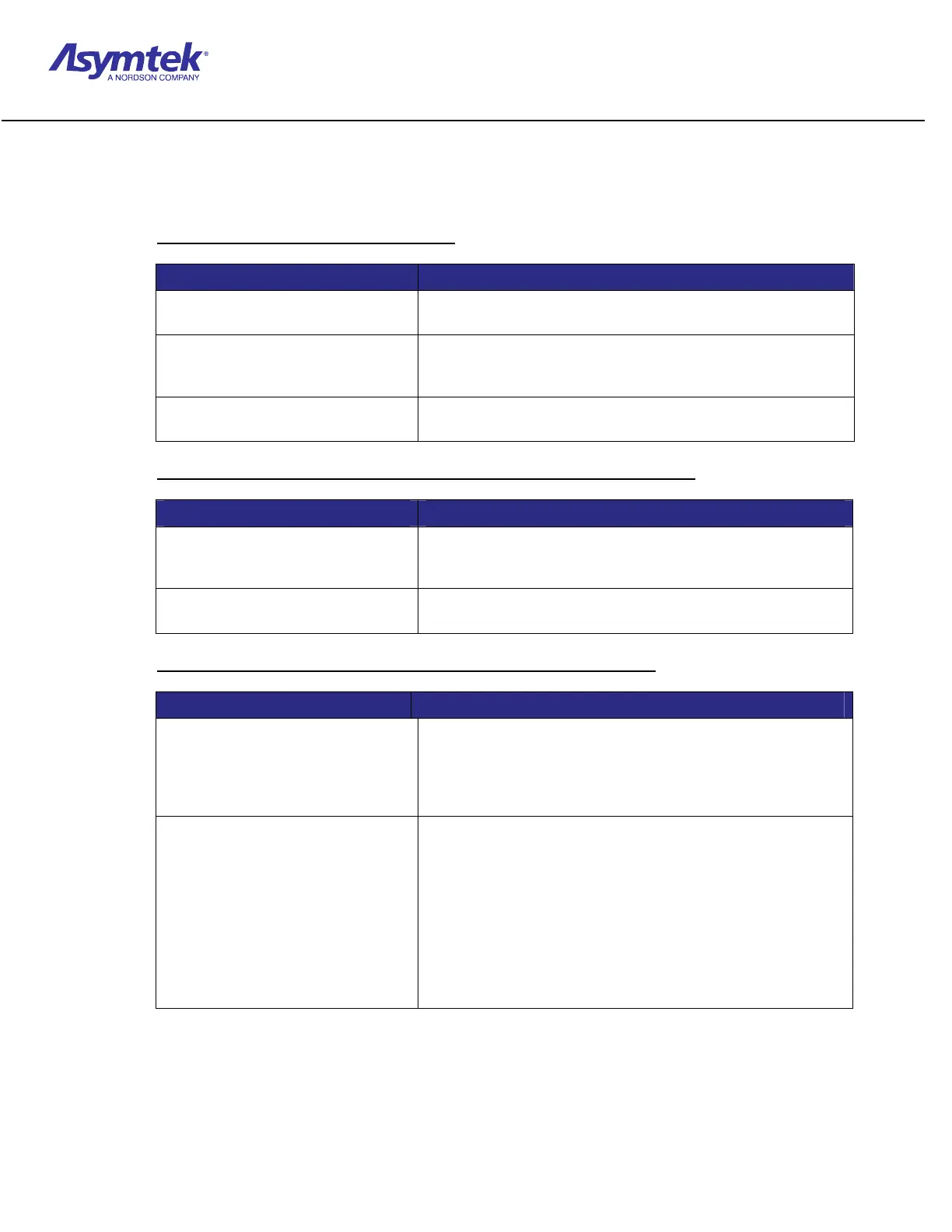

G. Fluid Not Escaping Through Nozzle

Possible Cause Recovery

1. Micrometer or Preload screw is

tightened all the way down

1. Adjust the Micrometer to the proper setting.

2. Cutout windows in extension

not aligned with fluid ports in

the lower body

2. Perform Disassembly and Cleaning procedure in Valve

Operations Manual. Check that cutouts are aligned.

3. Fluid air pneumatic or main air

regulator not connected

3. Check fluid air and main air pneumatics; tighten

connections if necessary.

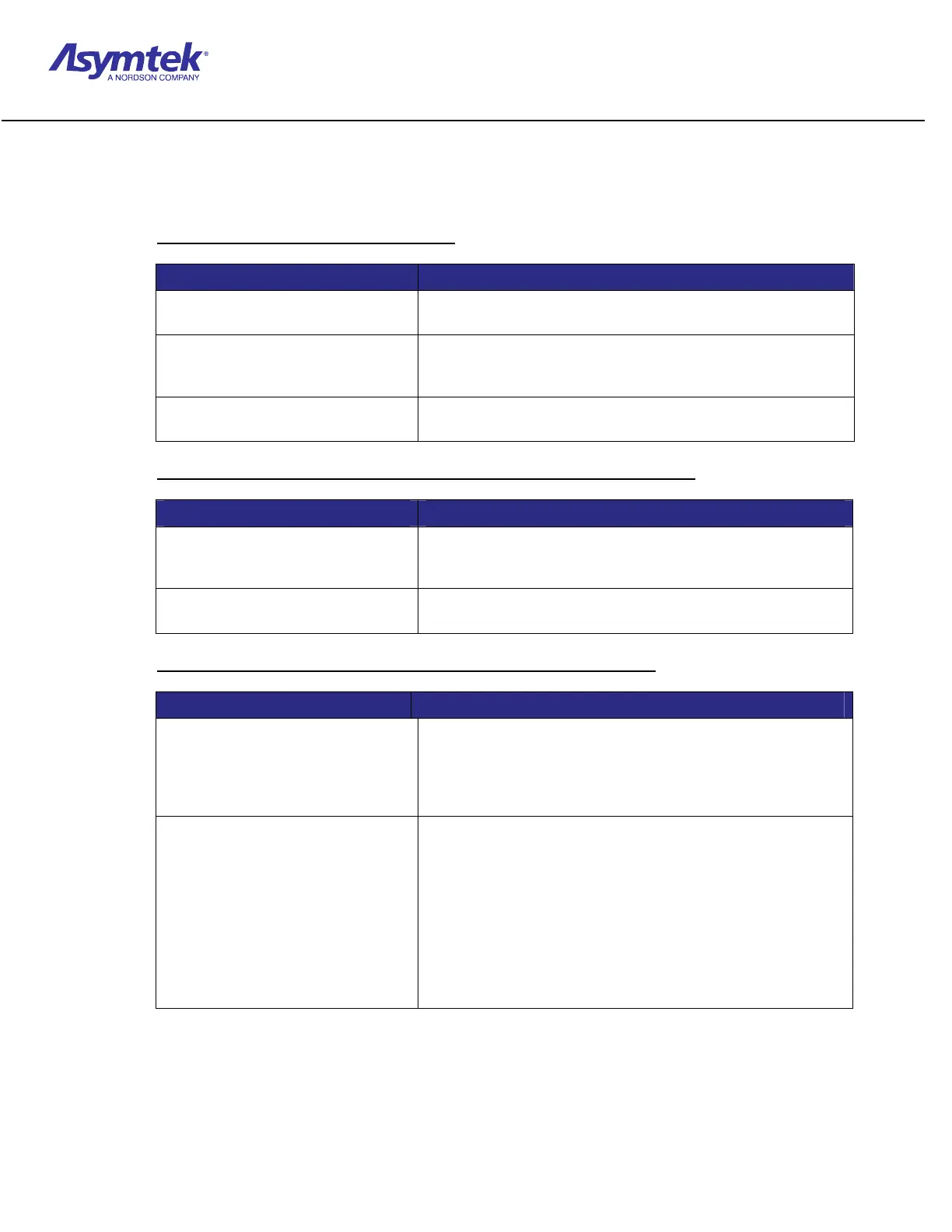

H. Fluid Leaking Through Hole In Extension While Not Dispensing

Possible Cause Recovery

1. Air piston seal may be worn

out, damaged, or may have

slipped out of position

1. Replace or adjust air piston seal. Refer to “Replacing

the Air Piston” and “Adjusting the Air Piston” in DJ-2000

Operations Manual.

2. Extension seat may be broken

2. Replace needle and extension. Refer to DJ-2000

Operations Manual.

I. Fluid Leaking Through Weep Hole On Sides Of Upper Body

Possible Cause Recovery

1. Worn needle

1. Inspect the needle for wear and replace if necessary.

Refer to “Replacing the Needle and Extension” in Valve

Operations Manual. (Excessive wear will appear as a

polished, indented band around the middle of the

needle, where it meets the U-cup seal.)

2. No lower seal or damaged seal

2. Install a new seal using the following steps:

Refer to the procedure “Cleaning the DJ-2000” in DJ-

2000 Operations Manual.

Complete the procedure “To remove the DJ-2000 from

the dispensing system.”

Follow the procedure “To disassemble and clean the

DJ-2000” through Step 16. (You can skip Step 4, the

nozzle cleaning process.)

Follow the procedure “To reassemble the DJ-2000.”

Loading...

Loading...