Error Processing

You execute motion control instructions to implement motion control with the MC Function Module.

When motion control instructions are executed, input parameters and instruction processing are

checked for errors.

If an error occurs in an instruction, the Error

output variable from the instruction changes to TRUE and

an error code is output to ErrorID output variable.

There are two ways that you can use to program processing of errors for motion control instructions.

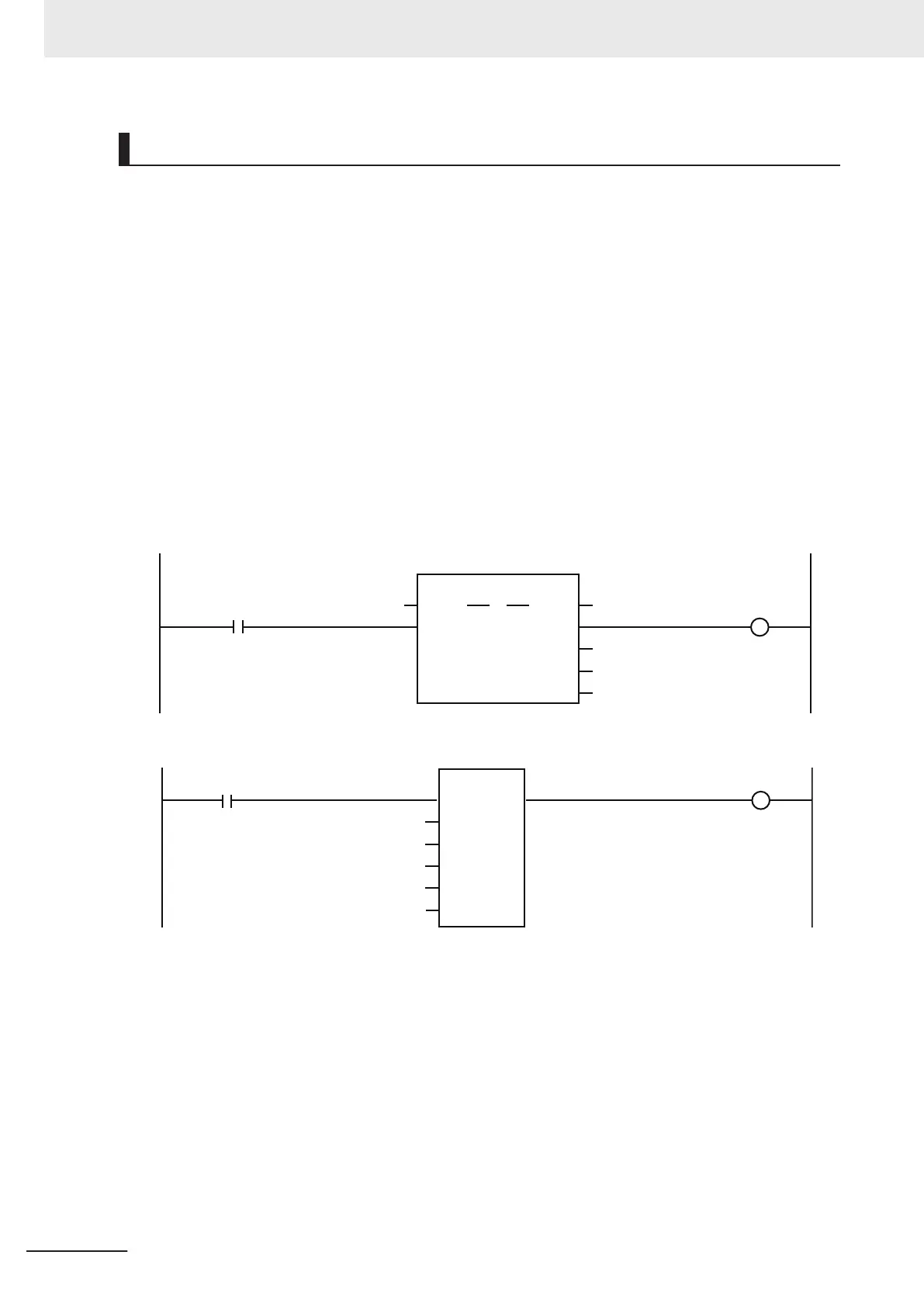

Error Processing for Individual Instructions

You can use the Error and ErrorID output variables from the instruction to process errors that occur

for each instruction.

The following example shows how to determine if an Illegal Axis Specification occurs for the in-

struction with the instance name PWR1.

The instructions are programmed so that error processing is executed if NoAxisErr changes to

TRUE.

Turning ON the Servo

Enable Status

ErrorID

PWR1

E

rror

MC_Power

Axis Axis

Busy

MC_Axis000

Pwr1_En

Pwr1_Status

Pwr1_Bsy

Pwr1_Err

Pwr1_ErrID

Checking to See If the Specified Axis Exists

Pwr1_Err

In1

EQ

In2

EQ

In3

In4

In5

NoAxisErr

Pwr1_ErrID

WORD#16#5460

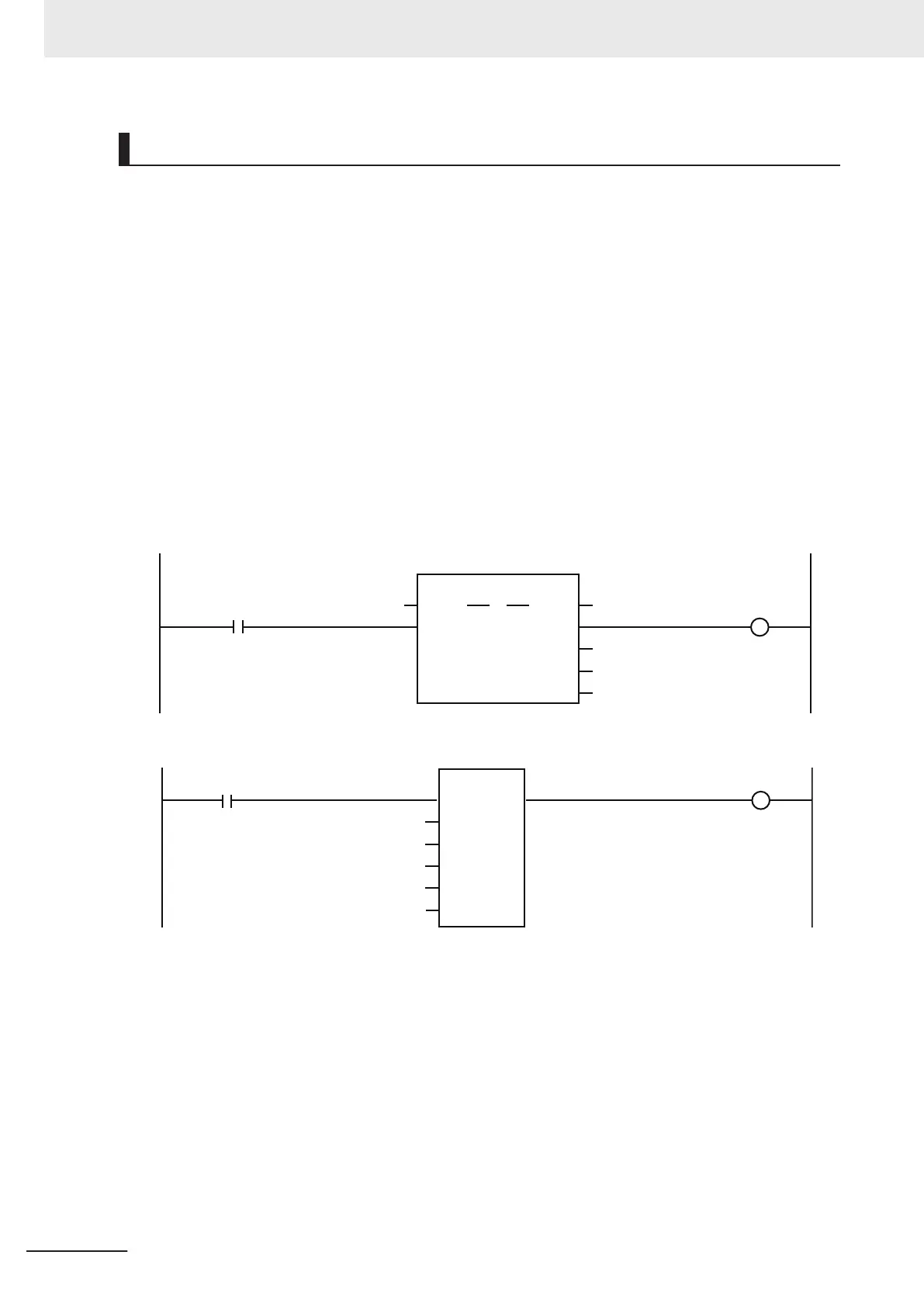

Error Processing for Different Types of Errors

You can use the error status that is provided by the system-defined variables for motion control to

process each type of error separately

.

The following example shows how to determine if a Slave Communications Error occurs for the ax-

is that is called MC_Axis000. The instructions are programmed so that error processing is executed

if ConnectErr changes to TRUE.

1 Introduction to Motion Control Instructions

1-4

NY-series Motion Control Instructions Reference Manual (W561)

Loading...

Loading...