Errors

If an error occurs during instruction execution, Error

will change to TRUE.

You can find out the cause of the error by referring to the value output by ErrorID (Error Code).

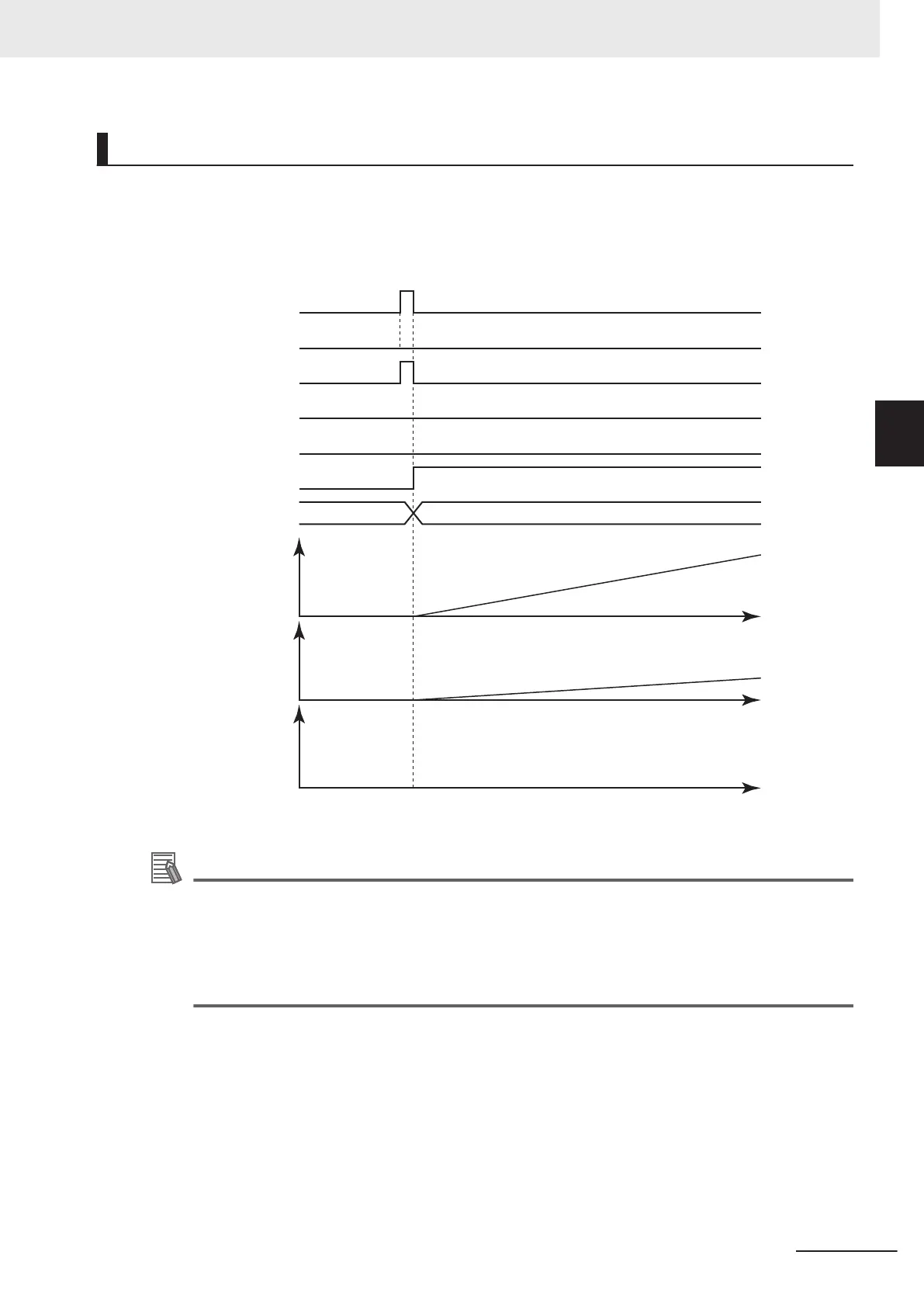

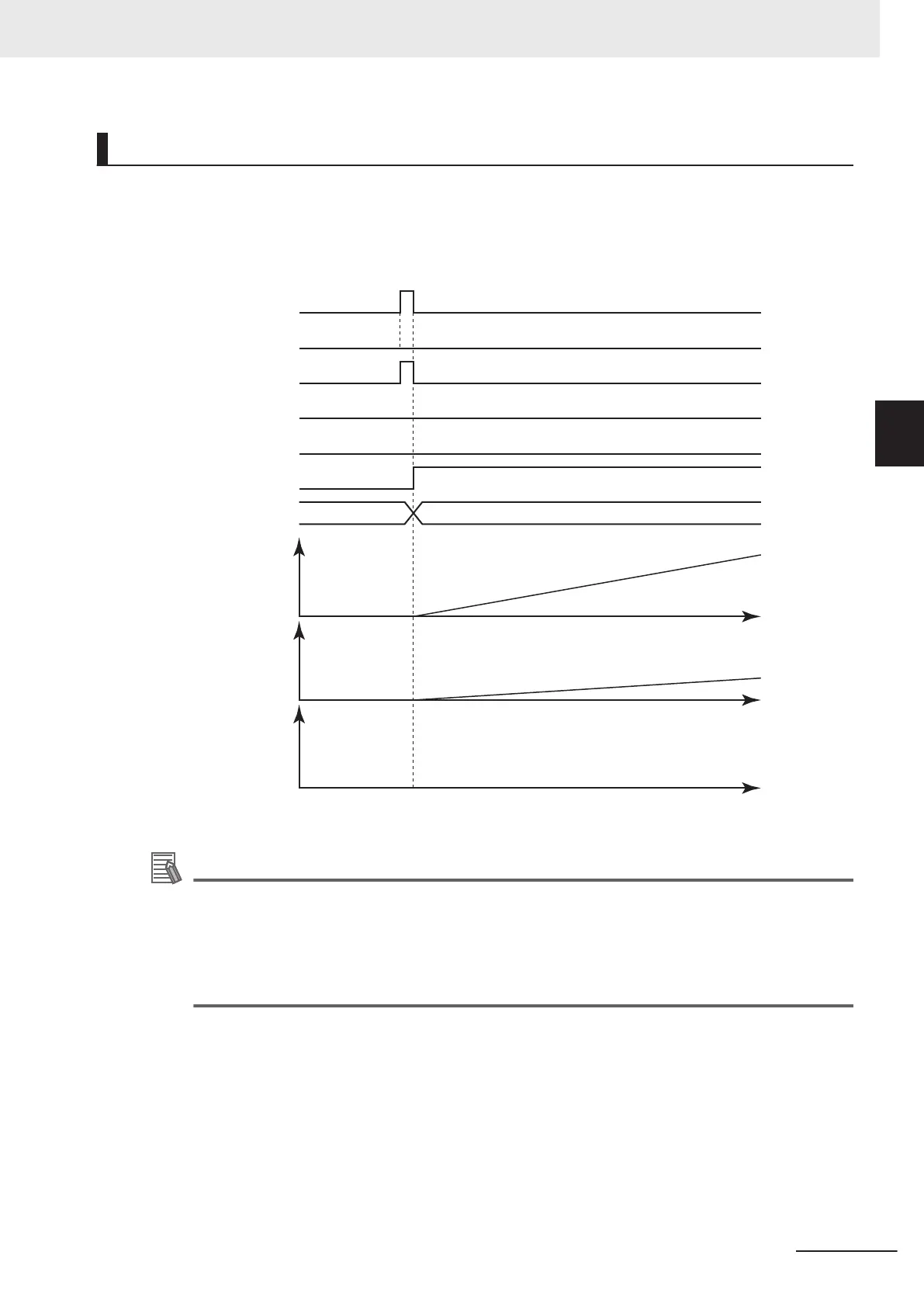

Timing Chart When Error Occurs

Error ID

Time

Time

Time

Slave axis position

Auxiliary axis position

Master axis position

16#0000

Execute

Busy

Active

InCombination

Comm

and Aborted

Error

ErrorID

Additional Information

• This instruction is not affected by errors in the Master

(Master Axis) or the Auxiliary (Auxiliary

Axis).

• After the error is cleared and the Master (Master Axis) or the Auxiliary (Auxiliary Axis) is in

motion, the Slave (Slave Axis) will resume the combined positioning operation. The Master

(Master Axis) and the Auxiliary (Auxiliary Axis) are not affected if an error occurs for the slave

axis during startup or execution of this instruction, but this instruction is aborted.

If a minor fault level error occurs during instruction execution, CommandAborted will change to TRUE

and the axis will stop.

The axis decelerates to a stop at Maximum Deceleration that is set in the axis parameters.

Y

ou can find out the cause of the error by referring to the value output to the MFalutLvl.Code Axis Vari-

able for the Slave (Slave Axis).

3 Axis Command Instructions

3-325

NY-series Motion Control Instructions Reference Manual (W561)

MC_CombineAxes

3

Function

Loading...

Loading...