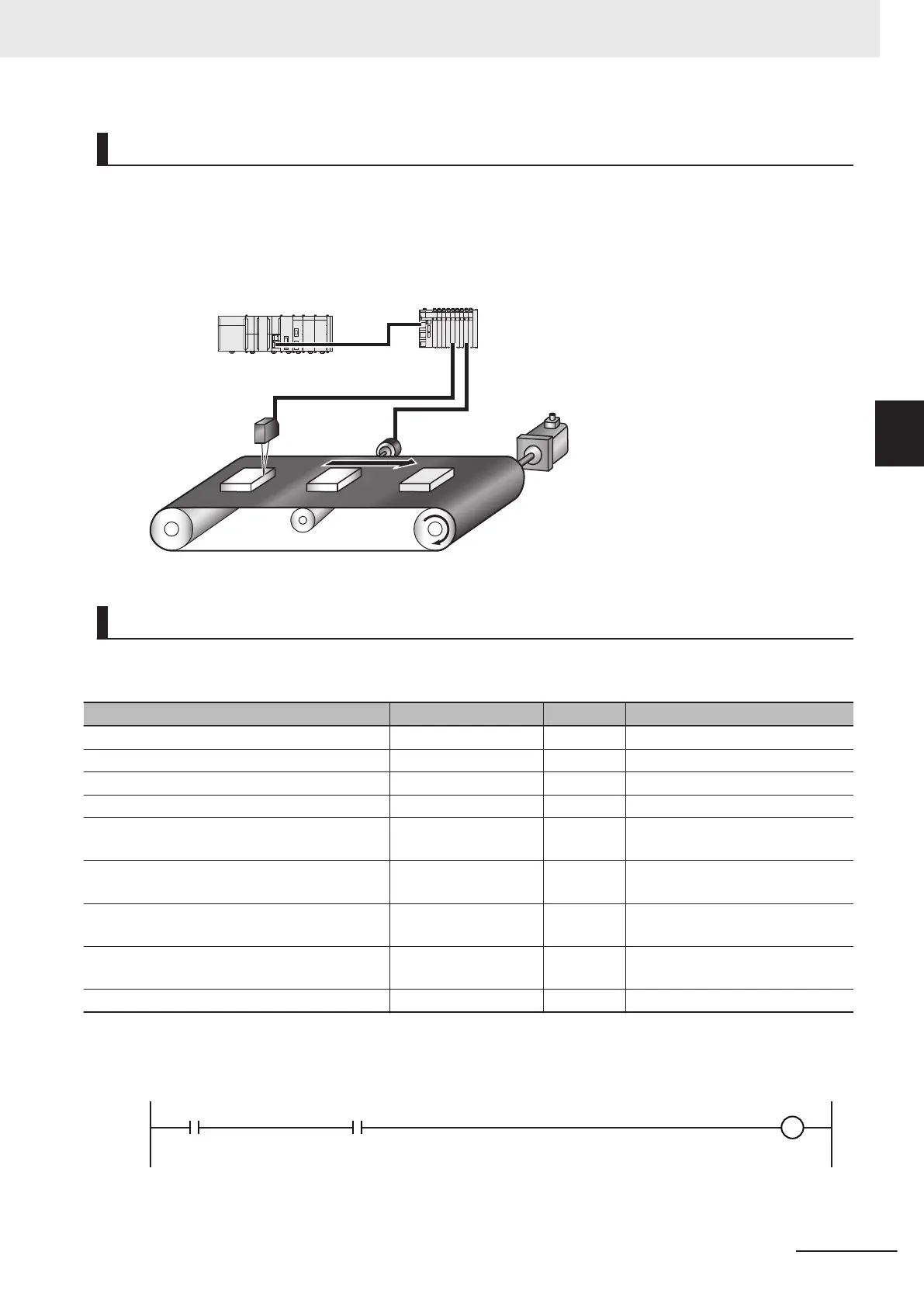

Operation Example

The sensor output turns ON when the sensor detects a workpiece. When the workpiece passes, the

sensor output turns OFF

. When the sensor detects the next workpiece, the sensor output turns ON

again.

The position of the encoder input is calculated based on the time stamp when the sensor output turns

ON. The difference between two positions is the distance between the workpieces.

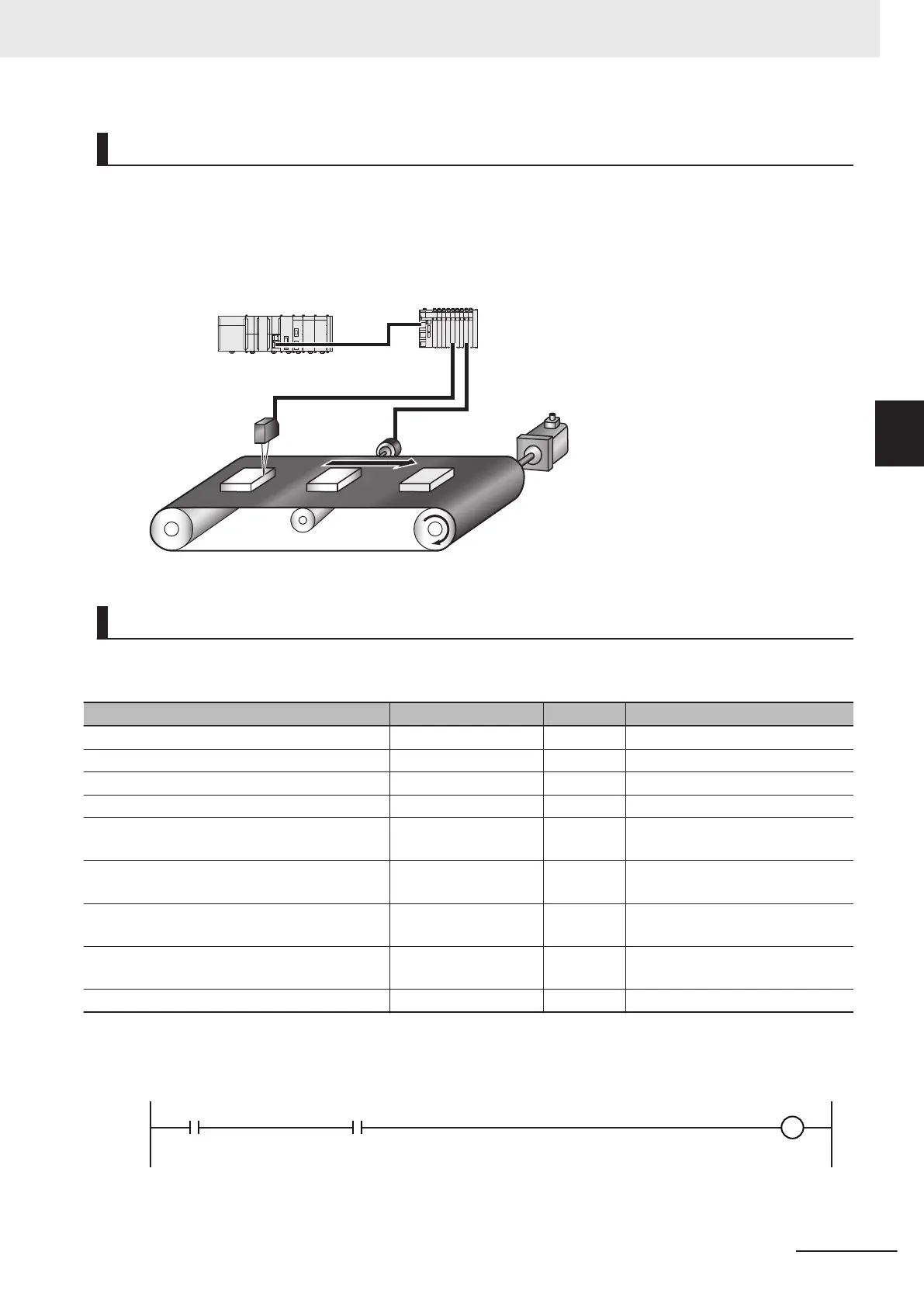

Ladder Diagram

Main Variables

Name Data type Default Comment

MC_Axis000 _sAXIS_REF --- Axis Variable for axis 1.

MC_Axis001 _sAXIS_REF --- Axis Variable for axis 2.

N3_Input_Bit_00 BOOL --- Device variable

N3_Input_Bit_00_Time_Stamp ULINT --- Device variable

Position ARRAY[0..1] OF

LREAL

--- Stores the calculated positions.

Count ARRAY[0..1] OF

ULINT

--- Stores the number of rotations.

FirstPoint UINT --- A variable that is used for proc-

essing.

LastPoint UINT --- A variable that is used for proc-

essing.

Distance LREAL --- The distance between workpieces.

Sample Programming

StartPg

Lock1

MC_Axis000.D

rvStatus.Ready

If StartPg is TRUE, check that the Servo Drive for axis 1 is ready.

3 Axis Command Instructions

3-441

NY-series Motion Control Instructions Reference Manual (W561)

MC_TimeStampToPos

3

Sample Programming

Loading...

Loading...