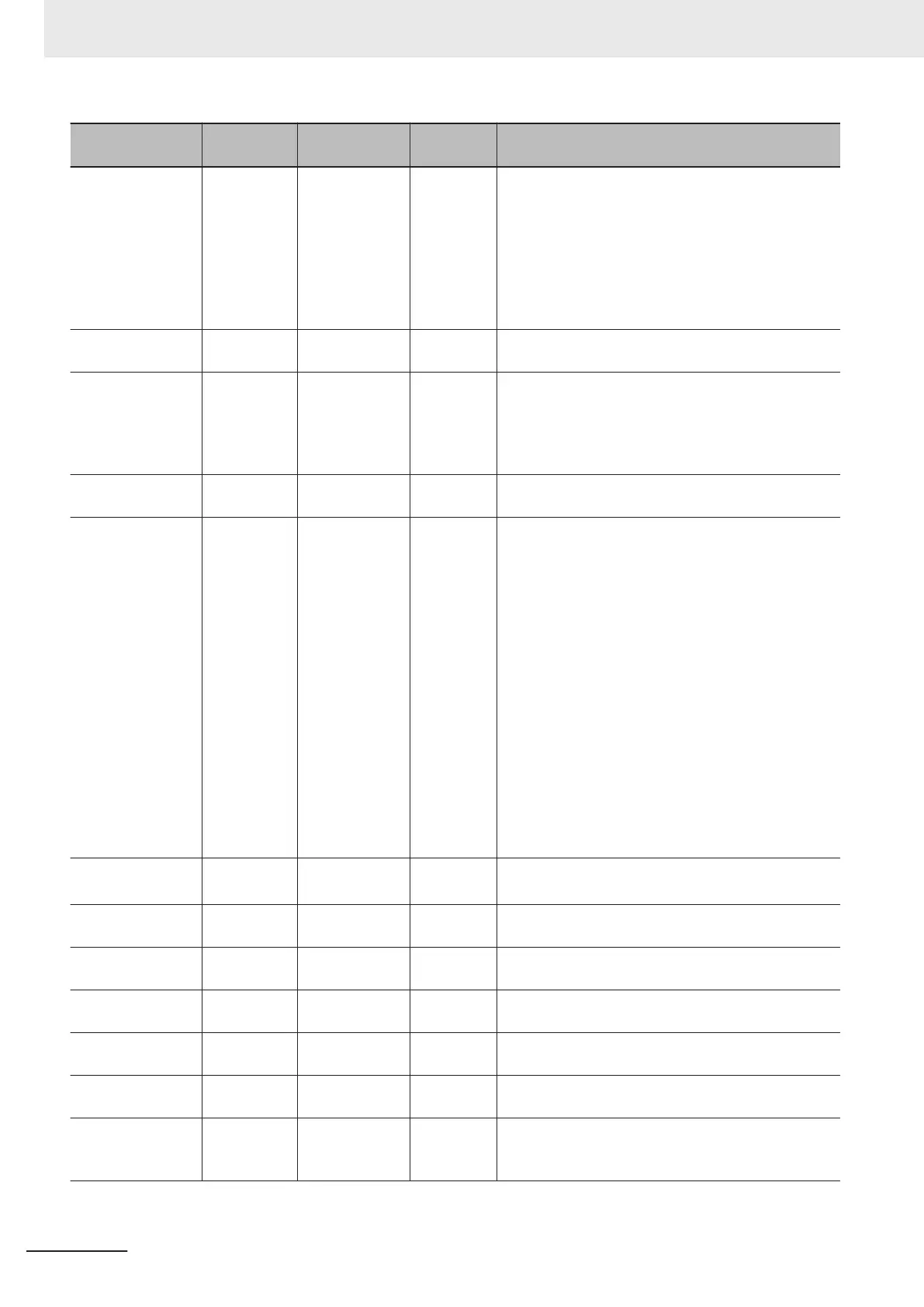

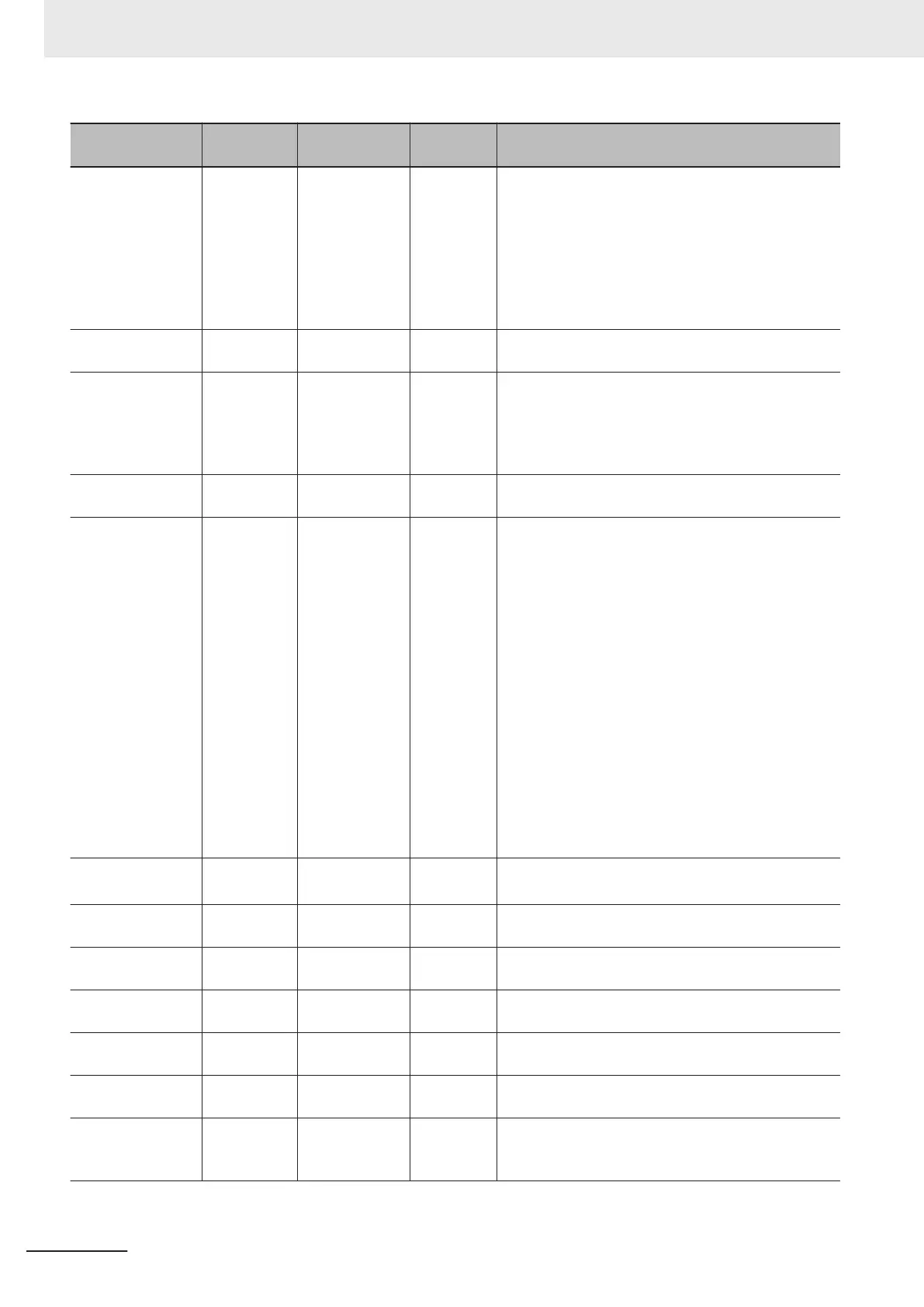

Name Meaning Data type

Valid

range

Description

Done Done BOOL TRUE or

F

ALSE

TRUE when the instruction is completed.

At this time, output variables Active, Error, and

CommandAborted are FALSE.

Done will be TRUE for at least one period if the input

variable Execute is FALSE when the instruction is

completed.

If Execute is TRUE, Done remains TRUE until

Execute changes to FALSE.

Busy Executing BOOL TRUE or

F

ALSE

Changes to TRUE when an instruction is acknowl-

edged.

Active Controlling BOOL TRUE or

F

ALSE

Changes to TRUE when the instruction is executed.

This variable is TRUE while the instruction is actually

controlling an axis or axes group. At this time, output

variables Done, Error, and CommandAborted are

FALSE.

Enabled Enabled BOOL TRUE or

F

ALSE

Changes to TRUE when busy.

CommandAborted Instruction

Aborted

BOOL TRUE or

F

ALSE

TRUE when an instruction could not be executed or

when it was aborted during execution.

The instruction is not executed if there is an error

with the target axis or axes group. Similarly, the in-

struction is not executed while the target axis or axes

group is decelerating to a stop.

The instruction is aborted when another instruction is

executed, or if an error other than for this instruction

occurs.

At this time, output variables Done, Active, and Error

change to FALSE. If the instruction is aborted while

the input variable Execute is FALSE,

CommandAborted will be TRUE for at least one peri-

od.

If Execute or Enable is TRUE, CommandAborted re-

mains TRUE until Execute or Enable changes to

FLASE.

Error Error BOOL TRUE or

F

ALSE

TRUE when there is an error caused by a mistake in

an input variable or instruction processing.

*1

ErrorID Error Code WORD

*2

Contains the error code when an error occurs.

16#0000 indicates normal operation.

Failure Failure End BOOL TRUE or

F

ALSE

TRUE when the instruction was not executed correct-

ly.

Status Servo ON BOOL TRUE or

F

ALSE

TRUE when the device is ready for operation.

EndOfProfile End of Cam

Cycle

BOOL TRUE or

F

ALSE

Changes to TRUE when the cam table end point is

executed.

Index Index UINT Non-nega-

tive number

Contains the cam data index number.

StartSync Following BOOL TRUE or

F

ALSE

TRUE when acceleration/deceleration is started for

synchronization and the device is ready for opera-

tion.

2 Variables and Instructions

2-28

NY-series Motion Control Instructions Reference Manual (W561)

Loading...

Loading...